Efficient bisecting and sawing device for stone panel

A stone board and sawing technology, applied in stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of low efficiency, low yield, easy cracking, etc., and achieve high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

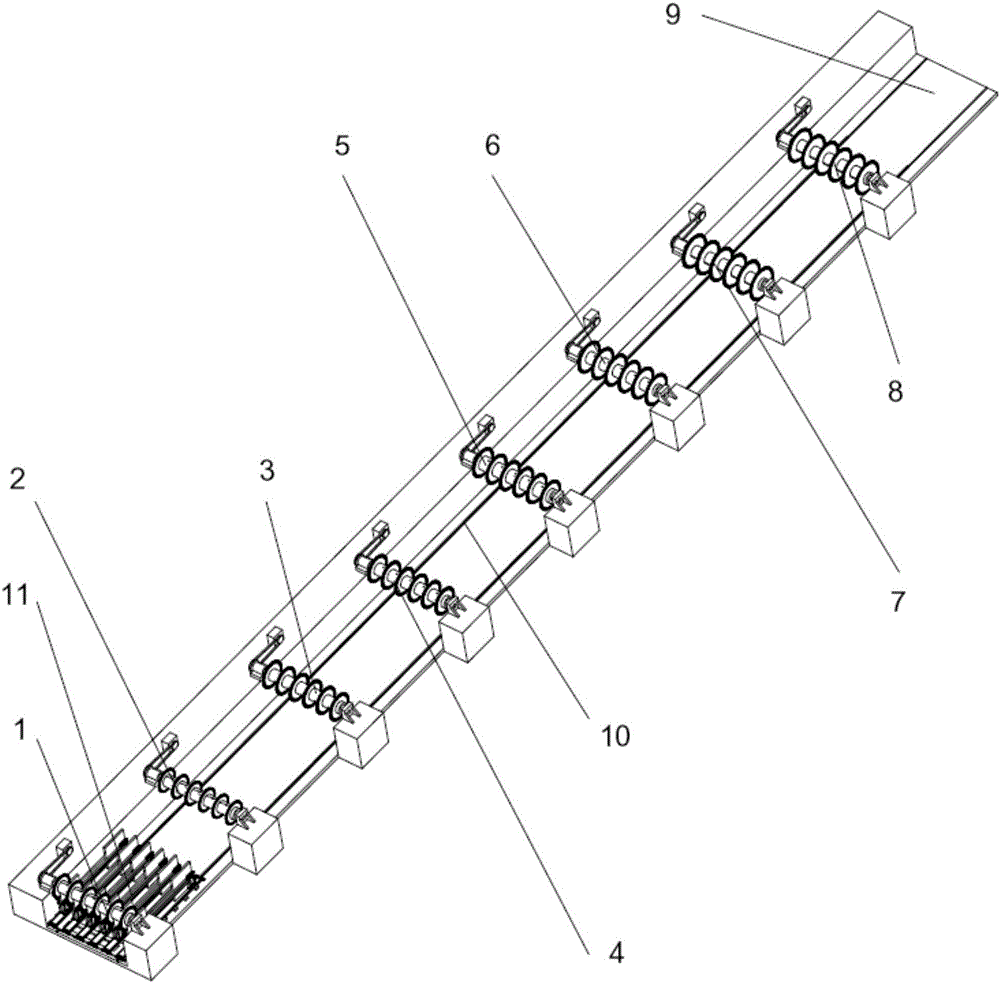

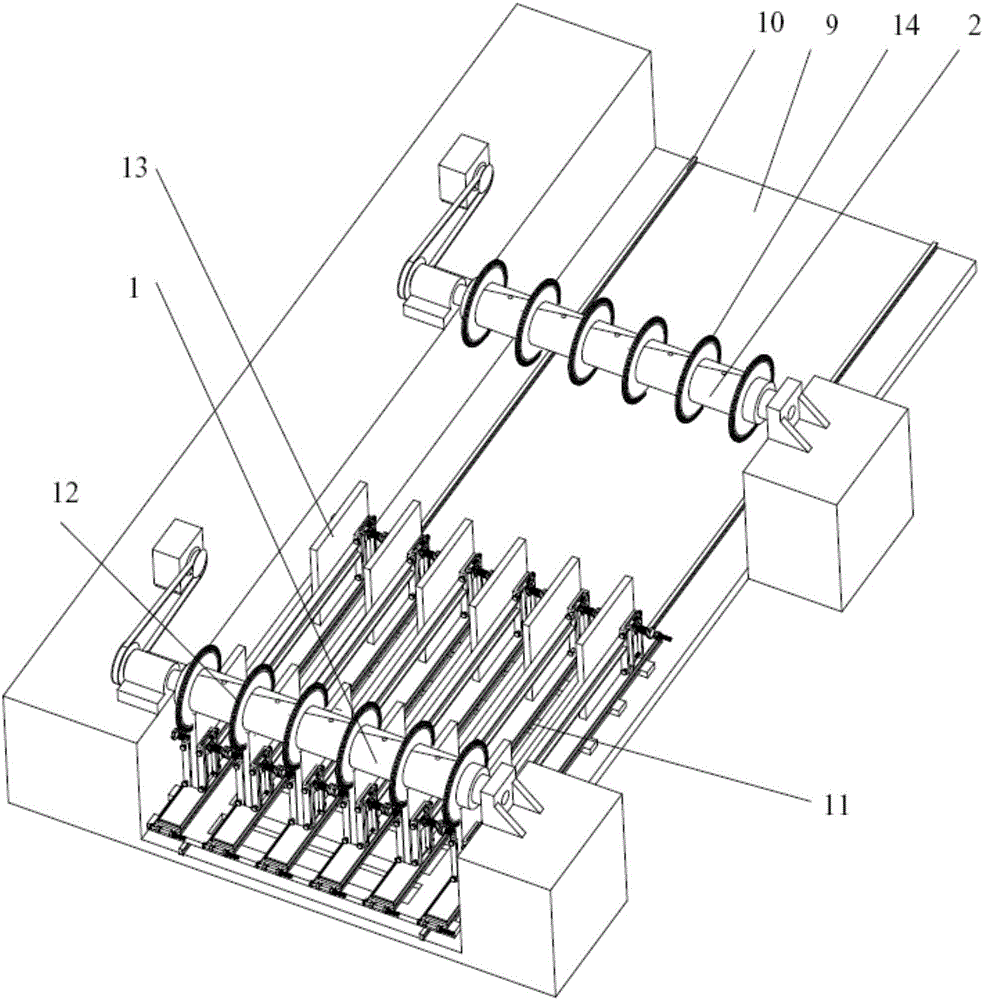

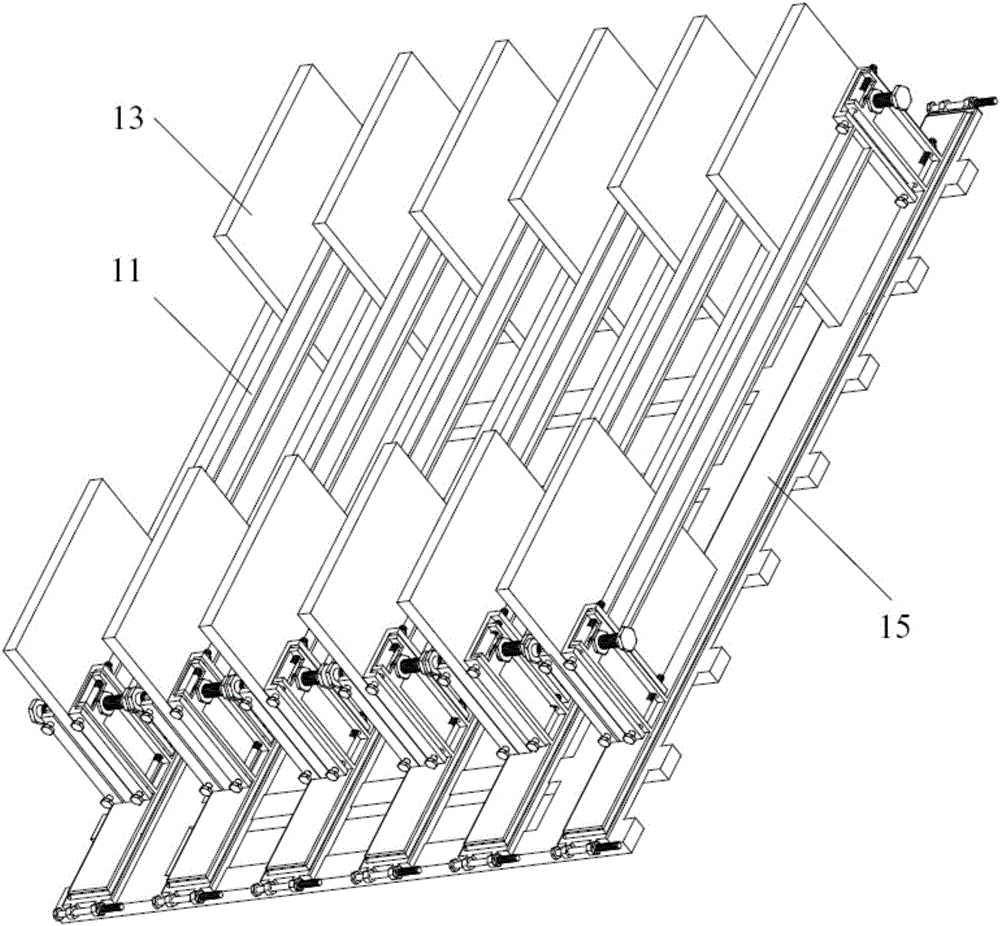

[0020] Embodiments of the present invention, such as Figure 1 to Figure 4 As shown, a high-efficiency half-section sawing device for stone slabs includes a wheel saw device and a clamping device after the stone slab 13 is vertically erected; a linear guide device is provided between the clamp device and the wheel saw device; the linear guide device The ground is provided with a long and straight bottom pit surface 9, and a track 10 is laid on the bottom pit surface 9. On the track 10, no less than one square plate-shaped frame car 15 driven by a synchronous device is installed on the track 10; The wheel saw device is that a plurality of wheel saw groups with equal shaft lengths are arranged along the laying of the rail above the track 10, and a plurality of circular saw blades are arranged at equal intervals along the axial direction on the wheel saw group. The number of circular saw blades is equal, the distance between the corresponding circular saw blades on each wheel saw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com