Automatic pressing machine mold for cylindrical refractory bricks, fully-automatic hydraulic brick pressing machine and brick pressing process

A technology for automatic presses and refractory bricks, applied in molds, forming indenters, manufacturing tools, etc., can solve the problems of refractory brick damage, short life, short continuous operation time, etc., to improve work efficiency, improve service life, mold The effect of wear reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

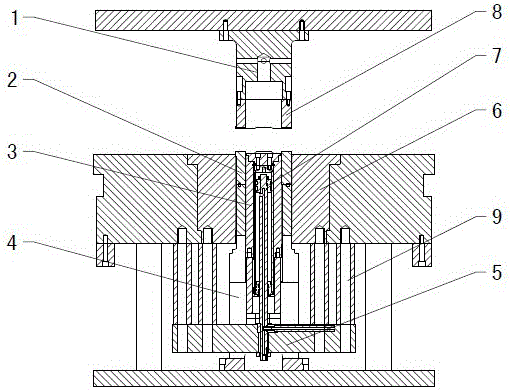

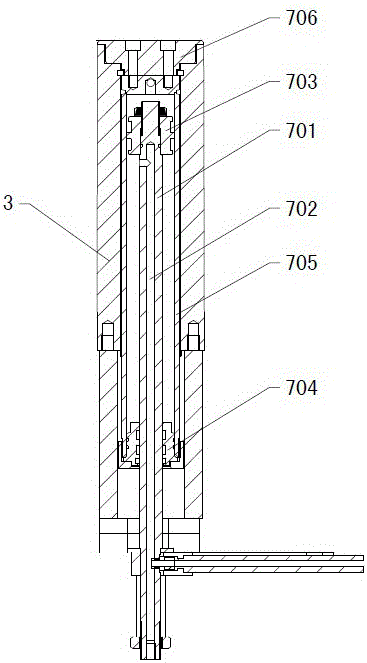

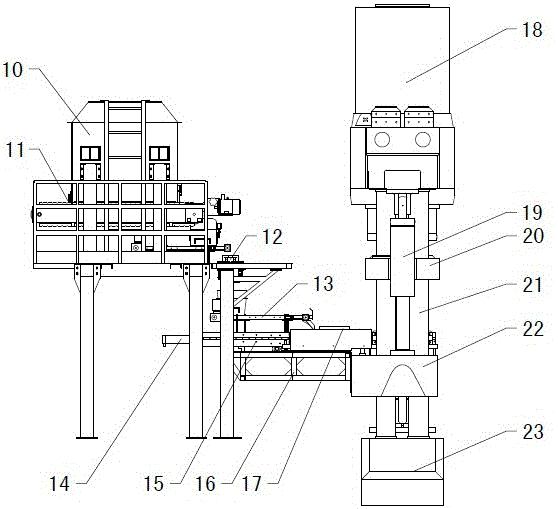

[0034] Figure 1~5 It is the best embodiment of the cylindrical refractory brick automatic press mold, fully automatic hydraulic brick press and brick pressing process. The following is combined with the attached Figure 1~5 The present invention will be further described.

[0035] refer to figure 1 , the cylindrical refractory brick automatic press mold includes an upper template 8, a lower template 2 and a middle frame, the upper template 8 is lifted and set above the lower template 2, the middle frame includes a mandrel 3 and a side plate 6, and the mandrel 3 is arranged on the lower The inner side of the formwork 2, the side plate 6 is arranged on the outer side of the lower formwork 2, and the middle frame and the lower formwork 2 rise and fall relative to form an annular mold cavity. The mandrel 3 is relatively movable, and the side plate lifting connection part pushes the mandrel 3 to rise, and the mandrel 3 is connected with a mandrel demoulding mechanism that drives...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com