An integrated UV curing and thermal curing system

A curing heat and thermal curing technology, applied in the direction of surface coating liquid device, coating, pretreatment surface, etc., can solve the problems of increasing product turnover time, increasing labor costs, unfavorable health of workers, etc., to prevent ultraviolet radiation Shooting, high degree of automation, convenient and stable grabbing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

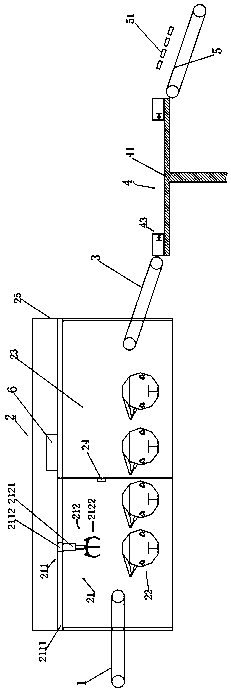

[0037] Such as figure 1 As shown, an integrated UV curing and thermal curing system includes a first conveyor belt 1 , a UV curing device 2 , a second conveyor belt 3 , a thermal curing device 4 and a third conveyor belt 5 arranged in sequence.

[0038] Product positioning grooves (not shown) are equidistantly arranged on the outer surface of the first conveyor belt 1 .

[0039] The ultraviolet curing device 2 is arranged between the first conveyor belt 1 and the second conveyor belt 3; the ultraviolet curing device 2 includes a UV curing chamber 25, a first grasping mechanism 21 arranged on the top of the UV curing chamber 25, and a The UV-resistant transparent door 23 on the side of the curing chamber 25 and the UV curing cylinder 22 arranged at the bottom of the UV curing chamber 25 .

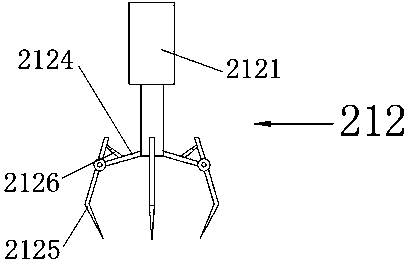

[0040] Such as figure 1 , 3 , 8, the first grabbing mechanism 21 includes a two-dimensional moving mechanism 211 and a claw assembly 212; The horizontal guide rail 2111 and the horizonta...

Embodiment 2

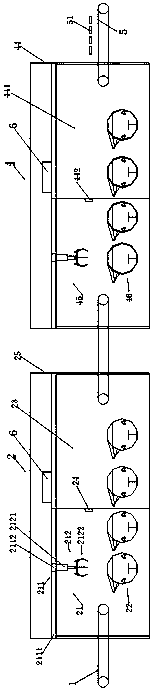

[0047] Embodiment two differs from embodiment one in that: as figure 2 , 7 , 8, the thermal curing device 4 is arranged between the second conveyor belt 3 and the third conveyor belt 5; 45 and the heat-curing cylinder 46 that is arranged on the bottom of the heat-curing chamber 44; the heat-curing chamber 44 has the same structure as the UV-curing chamber 25; the second gripping mechanism 45 has the same structure as the first gripping mechanism 21; Figure 7 As shown, the heat curing cylinder 46 includes a vertically arranged heat cylinder body 461, a heat cylinder product support 462 arranged in the heat cylinder body 461, and a heat radiation sheet 463 covering the inner wall of the heat cylinder body 461; The heating wire 435 is distributed in the interlayer between the sheet 463 and the heating cylinder 461 ; the heating cylinder 461 is also provided with a heating cylinder cover 464 ; the heating cylinder cover 464 is opened and closed by the sixth hydraulic device 465...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com