Single straw grabbing roller mechanism for corn straw feeding device

A technology of corn stalks and feeding devices, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of high labor intensity, high separation cost, and low work efficiency, so as to improve work efficiency, reduce labor intensity, and facilitate The effect of grabbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

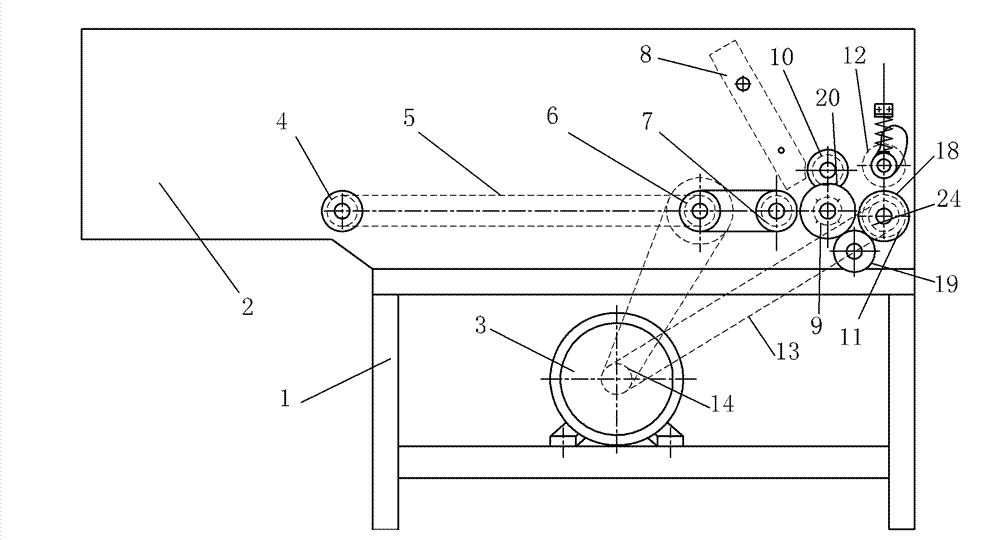

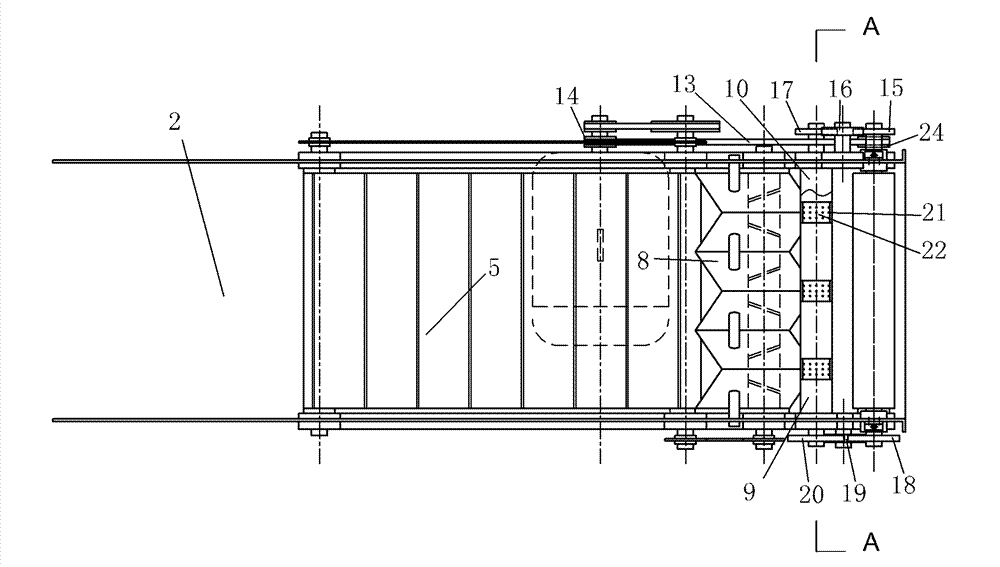

[0016] figure 1 , 2 Shown in , 3, 4 is the specific embodiment of the present invention, and it is to establish the grabbing roller mechanism of the single stalk of the corn stalk feeding device of the nail-type lower grabbing roller 9 of three sunken grooves; Its structure It includes the straw silo 2 on the frame 1, the motor 3 driving the belt drive and the chain drive to drive the conveying mechanism, the material shifting roller 7, and the plate type distributor 8 on the straw silo 2, which is characterized in that it is compatible with the plate type material distributor 8 On the front and rear sides of the frame 1 corresponding to the bottom position, the upper grab roller 10 is supported by the bearing 23, and the nail-type lower grab roller 9 parallel to the bottom surface of the upper grab roller 10, following the lower grab roller 9 Frame 1 is equipped with the following output roller 11, and the upper output roller 12 parallel to the top surface of the lower outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com