Steel wire hot-dip tank smoke conveying and purification components

A technology for purifying components and hot-dip tanks, which is applied in the direction of combined devices, chemical instruments and methods, and separation of dispersed particles, which can solve problems such as large suction of zinc pots, strong local wind, and physical injuries, so as to reduce energy consumption and avoid injuries , Avoid the effect of negative pressure suction with large displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

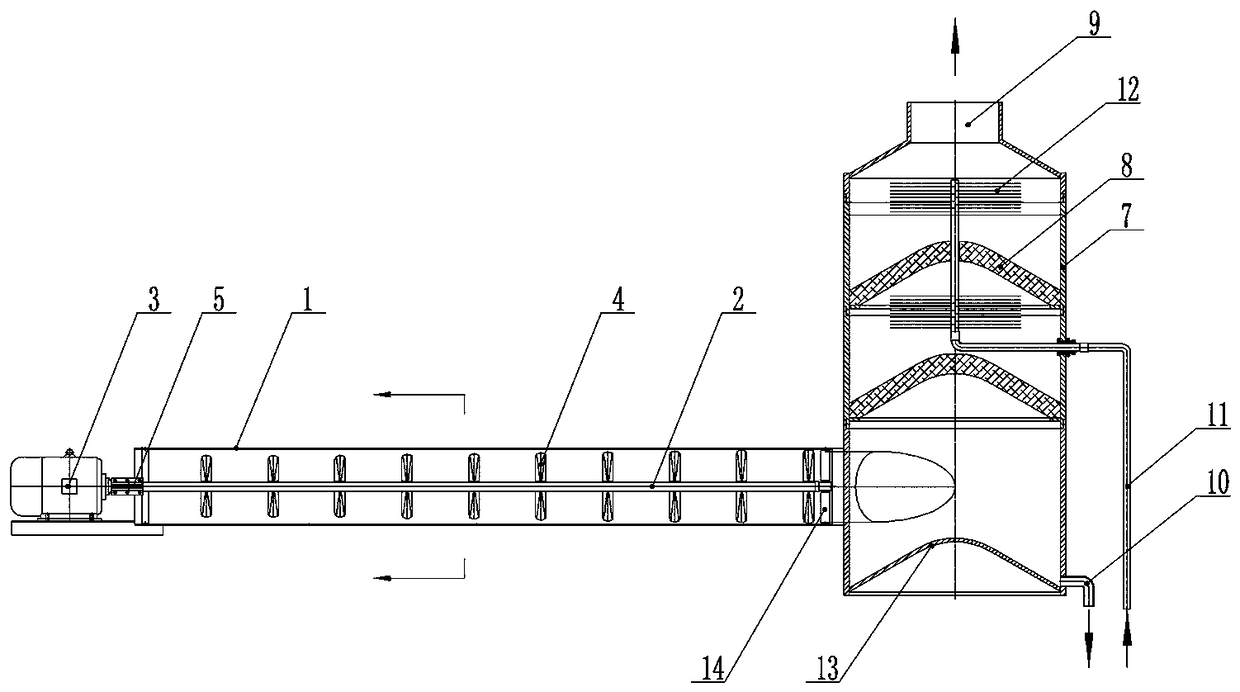

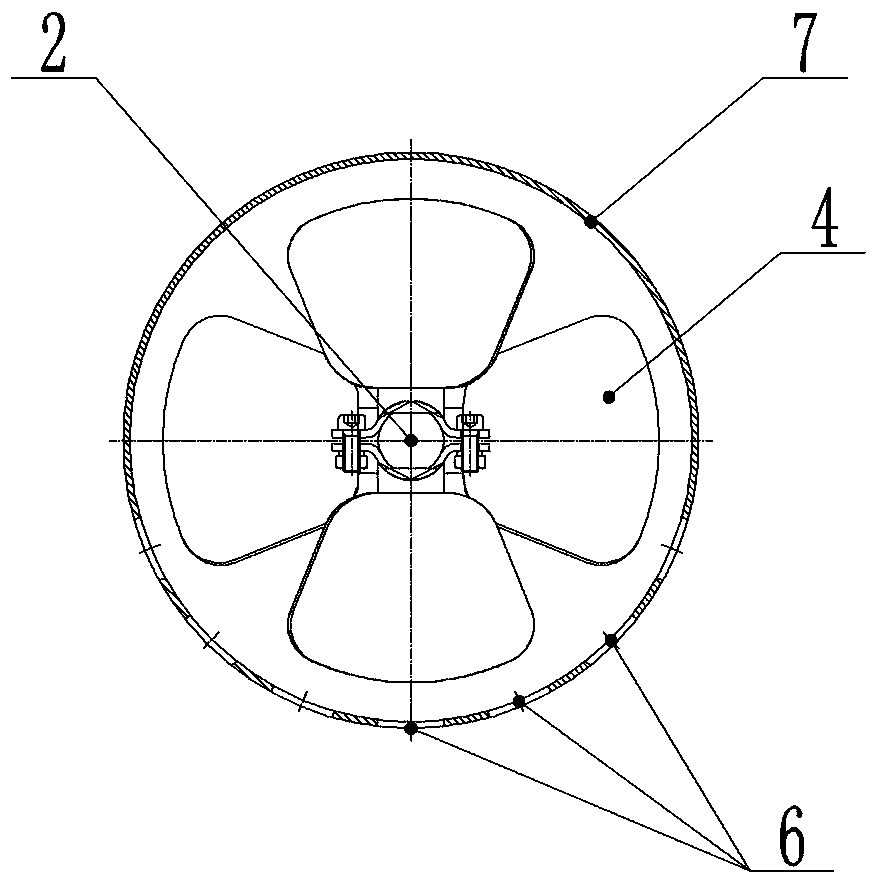

[0017] see figure 1 with figure 2 , a steel wire hot-dip tank body fume conveying and purifying assembly of the present invention includes a fume collecting and conveying assembly and a fume purifying assembly, and the fume collecting and conveying assembly includes a conveying air pipe 1 arranged horizontally, a fan arranged in the conveying air pipe 1 The shaft 2, the drive motor 3 arranged on the left end of the fan shaft 2, and the fan blades 4 arranged at equal intervals on the fan shaft 2, the delivery air duct corresponding to the right end of the fan shaft 2 is the air outlet, and the delivery air duct 1 There are a plurality of air inlet holes 6 in the lower part; the smoke purification assembly includes a housing 7, a filter element 8 arranged in the inner cavity of the housing 7, a spray assembly, an exhaust port 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com