Liquid retaining and liquid dropping preventing device for soap dispenser and working method of device

A soap dispenser and dripping technology, which is applied in the field of soap dispenser anti-residual dripping device, can solve the problems of waste and soap liquid cannot be stopped immediately, and achieve the effect of reducing soap liquid waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

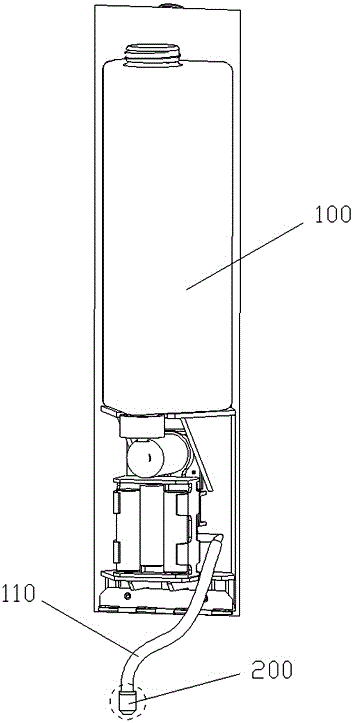

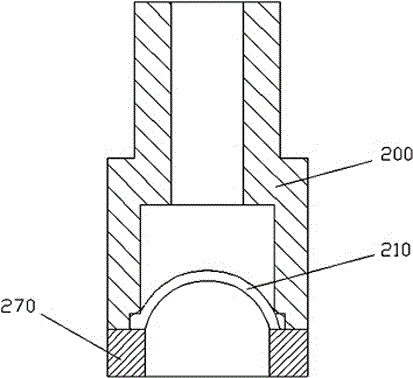

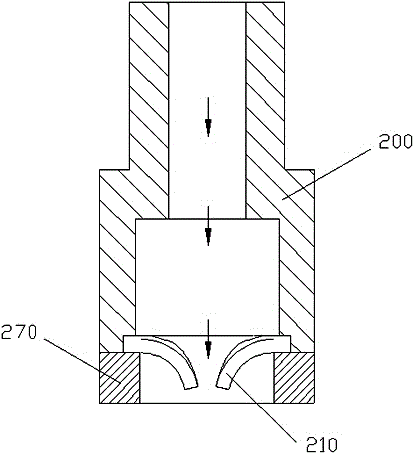

[0020] Such as Figure 1~5 Shown is Embodiment 1 of the present invention: a soap dispenser anti-residual dripping device, including a connecting sleeve 200 installed at the discharge end of the soap outlet pipe 110 of the soap dispenser 100, and the connecting sleeve 200 is provided with a device that is closed by its own elastic force. , The opening and closing device opened by fluid pressure.

[0021] In this embodiment, the opening and closing device is a silicone valve plate 210, and the silicone valve plate 210 is provided with a cutout 211 that is in a normally closed state and opened after being pushed by the fluid. The silicone valve plate 210 is installed on the connecting sleeve In the opening of the lower end, the lower end of the connecting sleeve 200 is provided with a fixing ring 270 for pressing the silicone valve plate 210. Under normal conditions, the cutout on the silicone valve plate 210 is tightly closed, so as to ensure that the blocking effect is achieve...

Embodiment 2

[0023] Such as Figure 6~7 It shows Embodiment 2 of the present invention: the difference between this embodiment and Embodiment 1 is that the structure of the opening and closing device is different. The closing device comprises a plug 130 at the lower end of the small-diameter hole 220 of the stepped hole, and a base 250 is arranged in the large-diameter hole 240 of the stepped hole, and a spring 260 whose upper end bears on the plug 230 is arranged on the base 250, so that A gap 241 is left between the base 250 and the inner wall of the large-diameter hole 240 of the stepped hole, which is conducive to the passage of fluid.

[0024] Under normal conditions, the plug 130 pushes against the lower end of the small-diameter hole 220 under the push of the spring 260, so as to ensure the blocking effect. Opening downwards, the spring 260 is compressed, the soap dispenser is closed and the pressure is relieved, and the plug 130 is pushed upward by the spring 260 to reset to block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com