High-temperature superconducting linear induction motor driving apparatus used for linear traction

A linear induction motor and high-temperature superconducting technology, applied in the direction of electromechanical devices, electric components, electrical components, etc., can solve the problems of small thrust, small air gap, large loss, etc., and achieve large thrust, light weight, reliability and service life Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be explained in detail below in conjunction with examples with reference to the accompanying drawings.

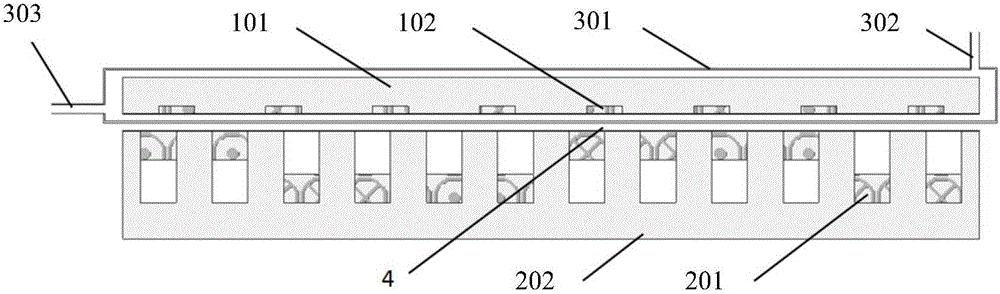

[0021] refer to figure 2 and Figure 7 , a high-temperature superconducting linear motor drive device for linear traction, with a primary assembly, a secondary assembly and a cooling system (cooling liquid inlet and outlet 303, cryogenic container 3, vent hole 302, cooling equipment 304, cooling liquid inlet pipe valve 305 and The coolant outlet valve 306) is formed.

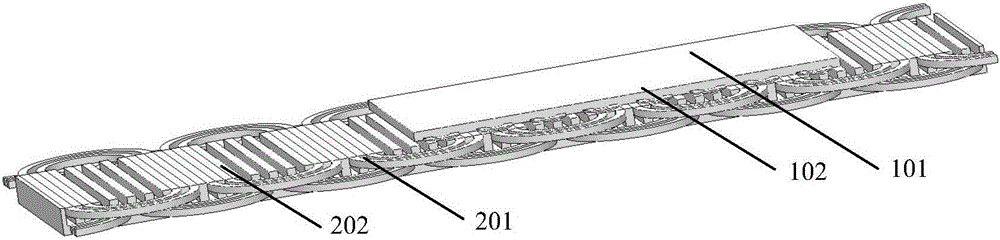

[0022] refer to image 3 , Figure 4 and Image 6 , the high-temperature superconducting coil 102 adopts a pie-shaped structure and a racetrack cross-section, and the windings are arranged in the slots of the secondary iron core 101 at the same interval; the high-temperature superconducting coil 102 and the secondary iron core 101 form a secondary assembly, and the secondary The assembly is placed in a cryogenic container 3 .

[0023] The iron core structure used by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com