Electric deicing pickaxe and deicing method

An electric and ice shovel technology, which is applied in the direction of electrical components, cable installation, overhead line/cable equipment, etc., can solve the problems of high-voltage transmission line damage, time-consuming and labor-intensive, affecting power supply stability, etc., and achieve good guiding effect and operation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

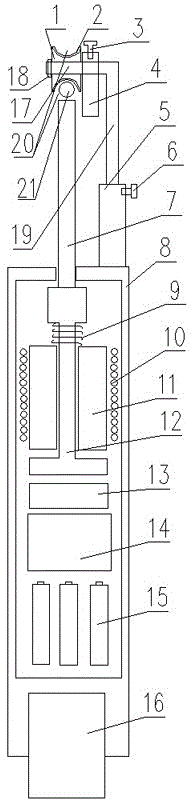

[0028] Such as figure 1 As shown, an electric deicing pick includes an insulating rod 16 and a housing 8 arranged on the insulating rod 16, a coil 10 is arranged in the housing 8, an iron core 11 is arranged in the coil 10, and an iron core 11 is arranged in the coil 10. The core is provided with a sliding armature 12, the sliding armature 12 is set with a return spring 9, the upper end of the sliding armature 12 is provided with a deicing shovel 7 protruding from the housing 8, and the housing 8 is provided with a deicing blade. Ice guide line protection mechanism.

[0029] The deicing guiding line protection mechanism includes a connecting rod 19 arranged on the housing 8 and a rotating shaft 17 arranged at the free end of the connecting rod 19, the rotating shaft is covered with a roller 1, and the peripheral side of the roller 1 is provided with a After the wire 21 matches the groove 20.

[0030] The groove is provided with a special wear-resistant and heat-resistant rub...

Embodiment 2

[0046] Such as figure 1 As shown, an electric deicing pick includes an insulating rod 16 and a housing 8 arranged on the insulating rod 16, a coil 10 is arranged in the housing 8, an iron core 11 is arranged in the coil 10, and an iron core 11 is arranged in the coil 10. The core is provided with a sliding armature 12, the sliding armature 12 is set with a return spring 9, the upper end of the sliding armature 12 is provided with a deicing shovel 7 protruding from the housing 8, and the housing 8 is provided with a deicing blade. Ice guide line protection mechanism.

[0047] The deicing guide line protection mechanism includes a connecting rod 19 arranged on the housing 8 and a rotating shaft 17 arranged at the free end of the connecting rod 19, the rotating shaft is covered with a roller 1, and the peripheral side of the roller 1 is provided with a After the wire 21 matches the groove 20.

[0048] The groove is provided with a special wear-resistant and heat-resistant rubbe...

Embodiment 3

[0058] An electric deicing pick, comprising an insulating rod 16 and a casing 8 arranged on the insulating rod 16, a coil 10 is arranged inside the casing 8, an iron core 11 is arranged inside the coil 10, and an iron core 11 is arranged inside the iron core. There is a sliding armature 12, and a return spring 9 is set on the sliding armature 12. The upper end of the sliding armature 12 is provided with a deicing shovel 7 protruding from the housing 8, and the housing 8 is provided with a deicing guide line protection agency.

[0059] The deicing guide line protection mechanism includes a connecting rod 19 arranged on the housing 8 and a rotating shaft 17 arranged at the free end of the connecting rod 19, the rotating shaft is covered with a roller 1, and the peripheral side of the roller 1 is provided with a After the wire 21 matches the groove 20.

[0060] The groove is provided with a special wear-resistant and heat-resistant rubber layer 2. The special rubber layer has go...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com