Converter steel-making endpoint determination method and system based on flame image CNN recognizing and modeling process

A flame image, converter steelmaking technology, applied in character and pattern recognition, instruments, computer parts, etc., can solve the problems that artificial features cannot represent complete information of flame blowing and are subjective, and cannot judge the end point of converter steelmaking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

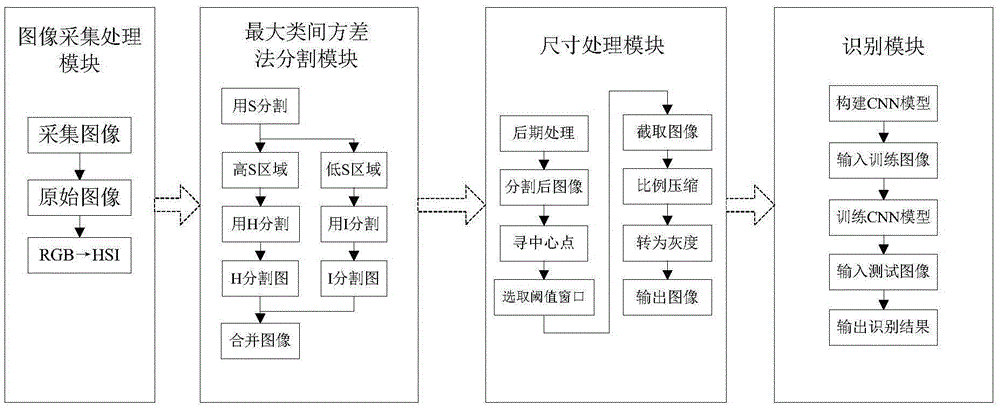

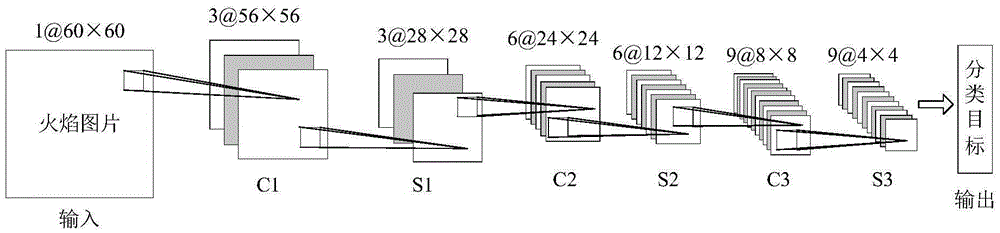

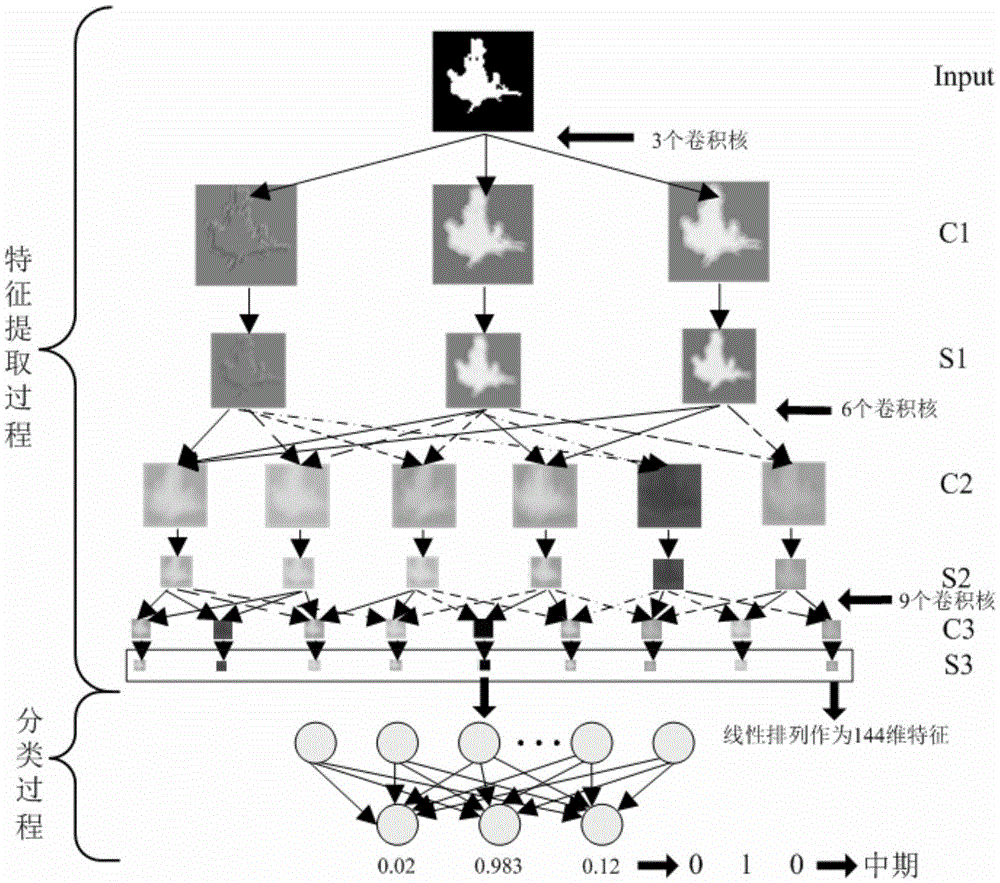

[0058] Example 1: Such as Figure 1-3 As shown, a method for determining the end point of converter steelmaking based on flame image CNN recognition modeling, the specific steps of the method are as follows:

[0059] Step1. Collect the flame image of the converter furnace mouth to provide data for the next image processing; the size of the collected image is 640×480;

[0060] Step2. First convert the collected flame image to HSI space. The relationship between HSI color space and RGB color space is shown in the following formula, where R, G, and B respectively represent the three components of red, green and blue:

[0061] I = 1 3 ( R + G + B ) ;

[0062] S = 1 - 3 R + G + B [ m i n ( R , G , B ) ] ;

[0063] H = arccos { [ ( R - G ) + ( R - B ) ] / 2 [ ( R - G ) 2 + ( R - B ) ( G - B ) ] 1 ...

Embodiment 2

[0083] Example 2: Such as Figure 1-3 As shown, a method for determining the end point of converter steelmaking based on flame image CNN recognition modeling, the specific steps of the method are as follows:

[0084] Step1. Collect the flame image of the converter furnace mouth to provide data for the next image processing;

[0085] Step2. First convert the collected flame image to HSI space. The relationship between HSI color space and RGB color space is shown in the following formula, where R, G, and B respectively represent the three components of red, green and blue:

[0086] I = 1 3 ( R + G + B ) ;

[0087] S = 1 - 3 R + G + B [ m i n ( R , G , B ) ] ;

[0088] H = arccos { [ ( R - G ) + ( R - B ) ] / 2 [ ( R - G ) 2 + ( R - B ) ( G - B ) ] 1 / 2 } G ≥ B ; 2 ...

Embodiment 3

[0109] Example 3: Such as Figure 1-3 As shown, a method for determining the end point of converter steelmaking based on flame image CNN recognition modeling, the specific steps of the method are as follows:

[0110] Step1. Collect the flame image of the converter furnace mouth to provide data for the next image processing; the size of the collected image is 640×480;

[0111] Step2. First convert the collected flame image to HSI space. The relationship between HSI color space and RGB color space is shown in the following formula, where R, G, and B respectively represent the three components of red, green and blue:

[0112] I = 1 3 ( R + G + B ) ;

[0113] S = 1 - 3 R + G + B [ m i n ( R , G , B ) ] ;

[0114] H = arccos { [ ( R - G ) + ( R - B ) ] / 2 [ ( R - G ) 2 + ( R - B ) ( G - B ) ] 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com