Spherical indentation method for predicting uniaxial stress-strain relationship of materials

A strain relationship and measurement method technology, applied in the direction of testing material hardness, analyzing materials, measuring devices, etc., can solve problems such as difficulty in forming and lack of theoretical foundation, and achieve the effect of solid theoretical foundation, concise form, and easy popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

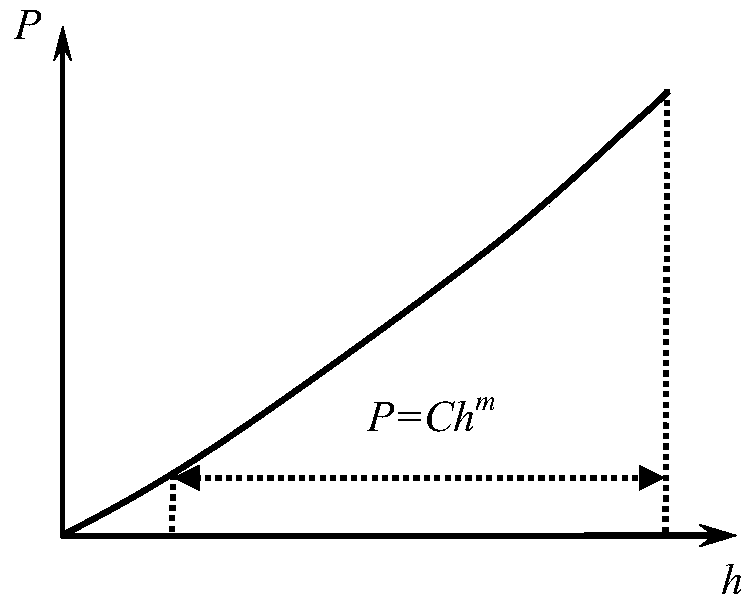

[0058] In the technical solution of the present invention, the present invention proposes a technical theory system for obtaining the uniaxial stress-strain relationship of materials by using spherical indentation based on equivalent energy theoretical derivation and a small amount of finite element simulation.

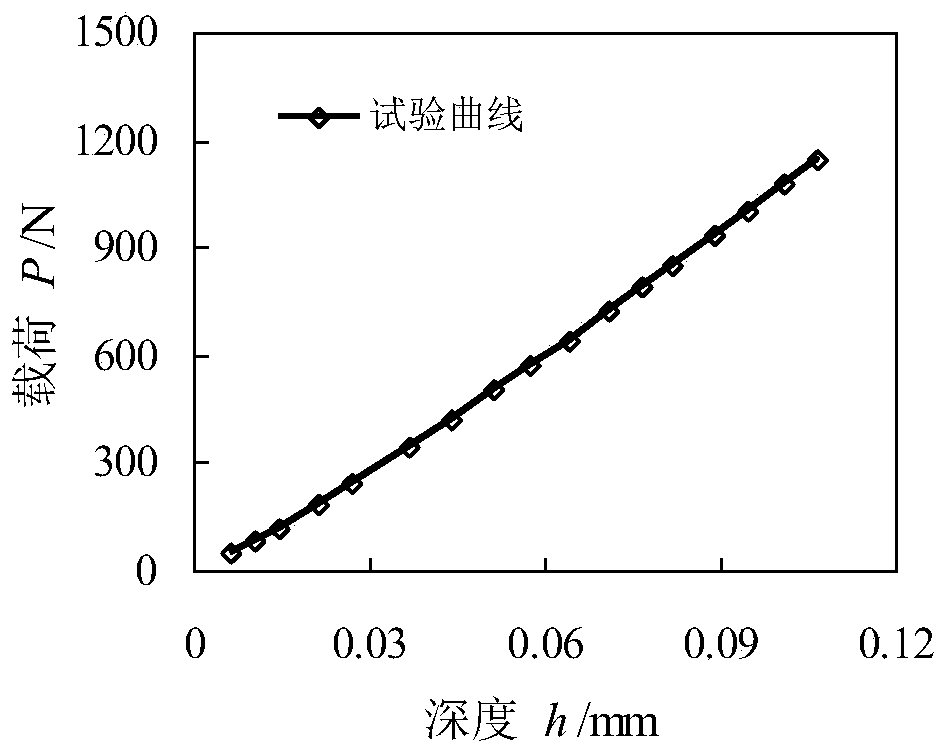

[0059] A 2 mm diameter cemented carbide spherical indenter is used to carry out indentation tests on small cylindrical samples of A105 steel (diameter 10 mm × height 10 mm) and obtain the uniaxial stress-strain relationship curve. image 3 The load P-depth h curve obtained during the indentation test is given. The data processing flow is as follows: firstly, zero-point correction is performed on the indentation load P-depth h curve, and about the last 90% of the fitting data (for example, figure 2 ) can get the loading curvature C and loading exponent m. Then, by substituting C and m into formula (6), the constitutive parameter σ of the measured material or componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com