Water and air mutual pressing box and water lifting system comprising same

A water-air, pressure box technology, applied in pressure pumps, machines/engines, non-displacement pumps, etc., can solve the problem of unreliable operation of magnetic switches and spring speed control mechanisms, easy loss of magnetism, and fluctuations in the highest and lowest positions of the water surface bigger problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

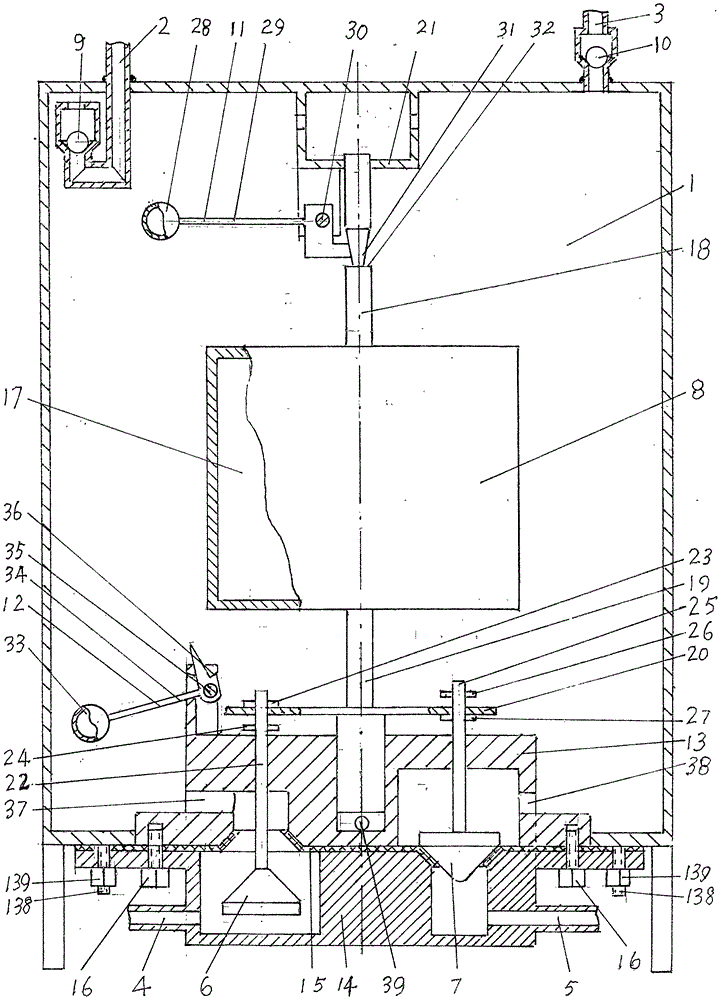

[0052] The water-gas mutual pressure box of embodiment 1 is as figure 1 shown. A water-air mutual pressure box, comprising a box body 1, an air inlet pipe 2, an air outlet pipe 3, a water inlet pipe 4 and a water outlet pipe 5, the air inlet pipe 2, the air outlet pipe 3, the water inlet pipe 4, and the water outlet pipe 5 are connected with the box body 1 and The inside of the box 1 is connected, the air inlet pipe 2 is connected in series with a check valve 9, the air outlet pipe 3 is connected in series with a check valve 10, the water inlet pipe 4 is connected in series with a valve 6, the water outlet pipe 5 is connected in series with a valve 7, and a float 8 is installed in the box body 1 , the float 8 cooperates with the valves 6, 7, the box body 1 is provided with the control mechanism 11, 12, the control mechanism 11, 12 cooperates with the float 8, the float 8 cooperates with the valve 6, 7 is the float 8 and the valve 6, 7 fit directly.

[0053] The intake pipe 2...

Embodiment 2

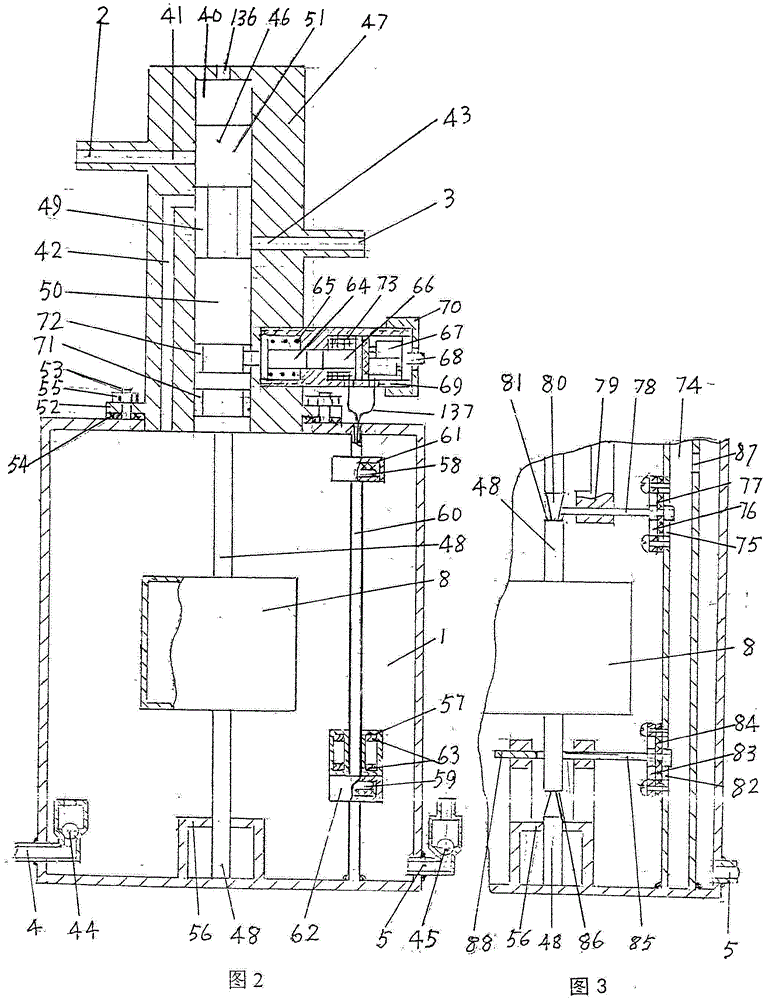

[0064] The water-gas mutual pressure box of embodiment 2 is as figure 2 shown. A water-air mutual pressure box, comprising a box body 1, an air inlet pipe 2, an air outlet pipe 3, a water inlet pipe 4 and a water outlet pipe 5, the air inlet pipe 2, the air outlet pipe 3, the water inlet pipe 4, and the water outlet pipe 5 are connected with the box body 1 and The inside of the tank 1 is connected, the inlet pipe 2 is connected in series with a valve 40, the outlet pipe 3 is connected in series with a valve 40, the water inlet pipe 4 is connected in series with a check valve 44, the outlet pipe 5 is connected in series with a check valve 45, and a float 8 is installed in the tank 1 , The float 8 cooperates with the valve 40, the box body 1 is provided with a control mechanism, the control mechanism cooperates with the float 8, and the cooperation between the float 8 and the valve 40 means that the float 8 directly cooperates with the valve 40.

[0065] The water inlet pipe 4...

Embodiment 3

[0076] The water-gas mutual pressure box of embodiment 3 is as image 3 , figure 2 shown. The water-gas mutual pressure tank of embodiment 3 is changed from the water-gas mutual pressure tank of embodiment 2. The water-air mutual pressure tank of embodiment 3 is mostly the same as the water-gas mutual pressure tank of embodiment 2, and there are only two differences. One is that the control mechanism is an elastic membrane automatic clamping control mechanism, and the other is that the outlet pipe 5 is not Any valve in series. This has just become described in the technical scheme, and the water-air mutual pressure box that the air inlet pipe is connected in series with valve, the air outlet pipe is connected in series with valve, the water inlet pipe is connected in series with check valve, and the water outlet pipe is not connected in series with any valve.

[0077] The elastic membrane automatic clamping control mechanism is arranged on the box body 1 inside the box bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com