Half-opened impeller stainless steel centrifugal pump

A centrifugal pump and semi-open technology, which is applied in the field of semi-open impeller stainless steel centrifugal pumps, can solve the problems affecting the performance of the conveying medium of the centrifugal pump, the wear of the pump body and its internal parts, and the inability to carry out medium conveying, etc., to achieve the working life. Prolonged, good sealing effect, high water absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

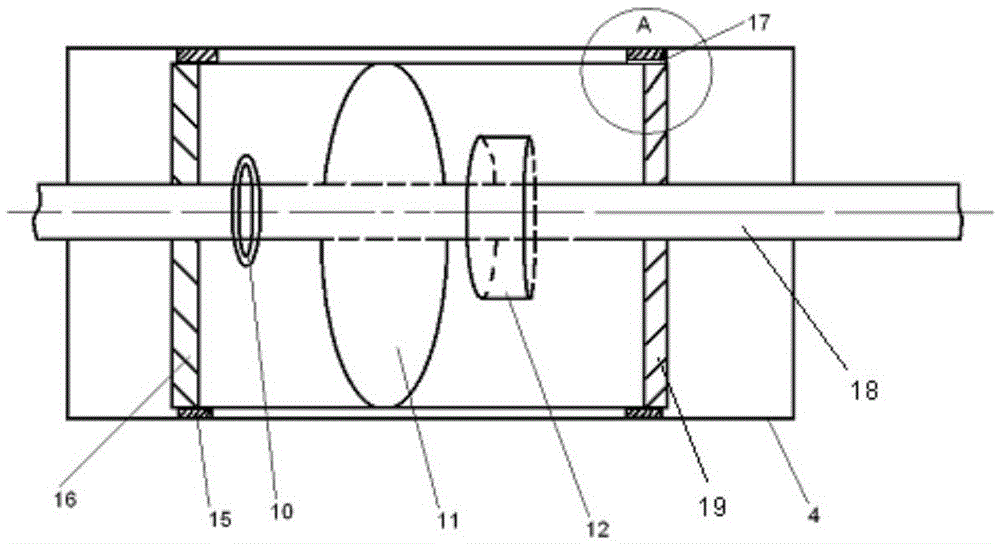

[0022] A semi-open impeller stainless steel centrifugal pump, including a pump casing assembly 4, an impeller 11, a bearing 18, a pump cover 13 and a motor 14, the impeller 11 is sleeved on the bearing 18 through a bushing, and one side of the impeller 11 The spring washer 10 is in contact with the first sliding sleeve 16, and the other side is in contact with the second sliding sleeve 19 through the mechanical seal 12. The mechanical seal 12 can pass through the second sliding sleeve 19 and be clamped on the In the cylindrical draw-in groove in the pump cover 13, the gap between the sliding retaining sleeve one 16 and the impeller 11 is adjusted by the retaining sleeve nut one 15, and the sliding retaining sleeve two 19 is adjusted by the retaining sleeve nut two 17 and The gap between the impellers 11, the impeller 11 is a semi-open impeller, the centrifugal pump also includes a dust cover 1, a middle O-ring 2, a hexagon socket bolt 3, a small O-ring 5, a screw Plug 6, large...

Embodiment 2

[0024] A semi-open impeller stainless steel centrifugal pump, including a pump casing assembly 4, an impeller 11, a bearing 18, a pump cover 13 and a motor 14, the impeller 11 is sleeved on the bearing 18 through a bushing, and one side of the impeller 11 The spring washer 10 is in contact with the first sliding sleeve 16, and the other side is in contact with the second sliding sleeve 19 through the mechanical seal 12. The mechanical seal 12 can pass through the second sliding sleeve 19 and be clamped on the In the cylindrical draw-in groove in the pump cover 13, the gap between the sliding retaining sleeve one 16 and the impeller 11 is adjusted by the retaining sleeve nut one 15, and the sliding retaining sleeve two 19 is adjusted by the retaining sleeve nut two 17 and The gap between the impellers 11, the impeller 11 is a semi-open impeller, the centrifugal pump also includes a dust cover 1, a middle O-ring 2, a hexagon socket bolt 3, a small O-ring 5, a screw Plug 6, large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com