Plug welding type double-steel plate composite shear wall

A technology combining shear walls and double steel plates, which is applied to walls, buildings, building components, etc., can solve the problems that the mechanical performance is controlled by welding performance, the influence of steel plate welding temperature, and the wall surface is not suitable for flatness, etc., so as to achieve excellent seismic performance, High bearing capacity and good overall collaborative work ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

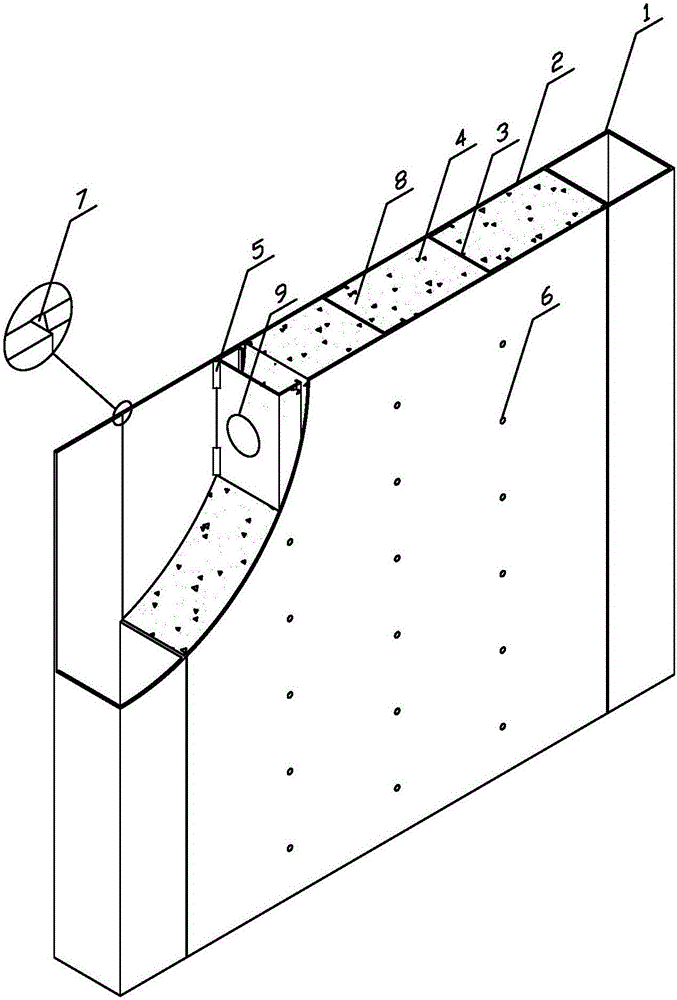

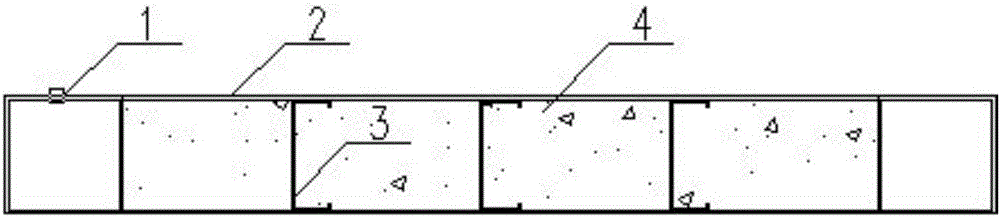

[0031] Please refer to Figure 1-3 , the present invention provides a plug-welded double steel plate composite shear wall, including a steel pipe column 1 at both ends, a pair of steel plates 2 and a plug-welded connector 3, and the two steel plates 2 are pulled by the plug-welded connector 3. The plug-welded connector 3 divides the cavity between the two steel plates 2 into at least two tubular cavities 8, and concrete 4 is poured in the tubular cavity 8, and the steel pipe columns at both ends are poured or not poured concrete as required, The two ends of the wall are strengthened by steel pipe columns. The thickness of the steel pipe is slightly thicker than that of the steel plate of the wall. Its function is equivalent to the dark column of the concrete shear wall. . The use of steel tube columns is convenient for the connection of composite walls and steel beams. The form and structure of wall-beam connection nodes can adopt mature specifications and recommended methods...

Embodiment 2

[0041] Please refer to figure 1 and image 3, the rest of the structure is the same as in Example 1, but the cross-section of the plug-welding connector 3 is Z-shaped, and the end of the Z-shaped plug-welding connector 3 can be folded inwardly, and the cross-section of the plug-welding connector is Z. Type and Z-type plug-weld connectors can be folded inwards at the end, and holes can be arranged on the web of the connector according to the fluidity requirements during concrete pouring, so that the concrete and steel plates can work together as a whole The ability is good, and the compactness of concrete pouring is also effectively guaranteed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com