Follow-up ground gripping type road surface ice and snow removing machine

An ice and snow machine and follow-up technology, applied in snow surface cleaning, cleaning methods, construction, etc., can solve the problems of occupying a lot of work space, consuming a lot of manpower and material resources, and icy roads with uneven heights, and achieve a simple and compact overall structure. Ensure deicing efficiency and save work space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

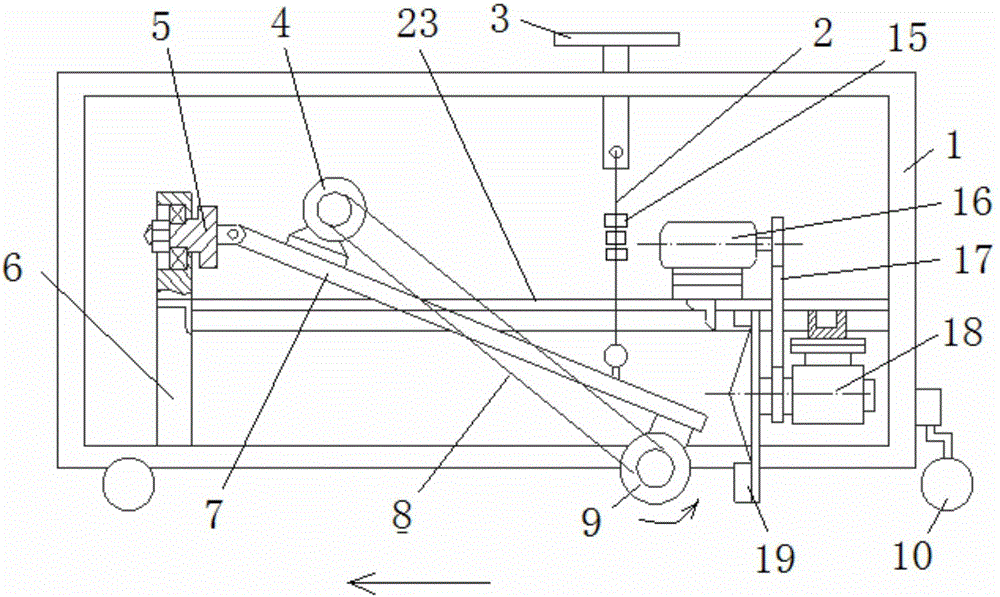

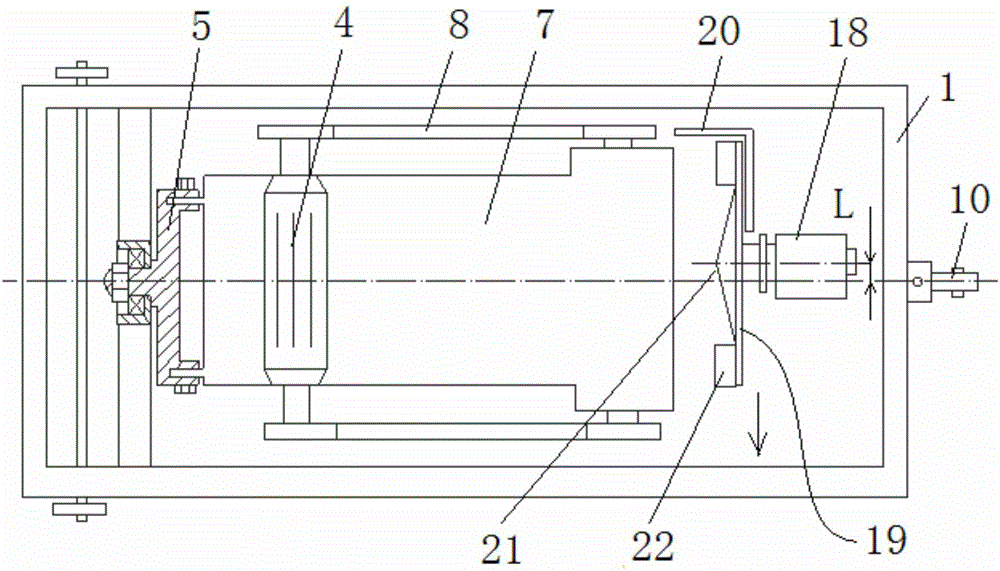

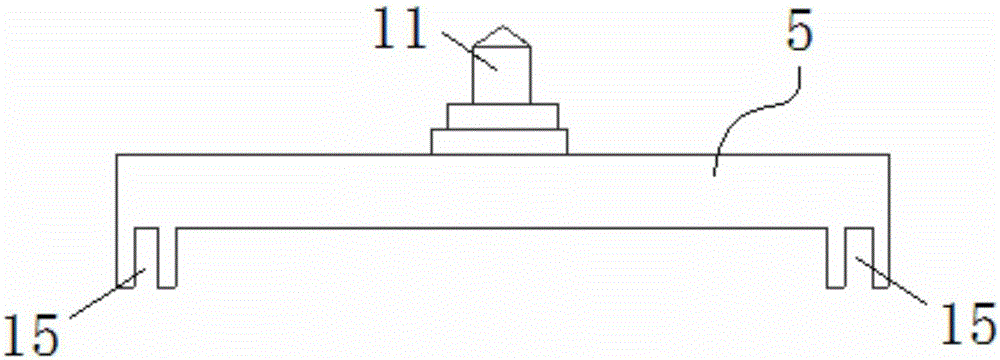

[0030] Such as Figure 1~2 As shown, the present invention includes a frame body 1, a drive plate 7, a drive plate connector 5, a drive device 4, a transmission mechanism 8, a deicing roller 9, a suspension mechanism and a cleaning mechanism, wherein a Bracket 6, the drive board connector 5 is rotatably mounted on the bracket 6, the drive board 7 is swingably mounted on the drive board connector 5, and the driving device 4 is arranged on the drive board 7 On the free end of the driving plate 7, there is a deicing roller 9, the deicing roller 9 is driven to rotate by the driving device 4, and the driving device 4 transmits torque through the transmission mechanism 8, the The free end of the drive plate 7 is suspended by the suspension mechanism, thereby adjusting the distance between the deicing roller 4 and the road surface, and the drive plate 7 is hinged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com