A disc-shaped electrode electrospinning device

A technology of electrospinning and disk-shaped electrodes, which is applied in textiles and papermaking, filament/thread forming, fiber processing, etc. It can solve the problems of unsuitable batch nanofiber manufacturing, uneven electric field distribution of spinning electrodes, and uneven fiber diameter. The problem of equalization can be achieved to improve spinning efficiency and spinning quality, accelerate fiber deposition and solidification, and save resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

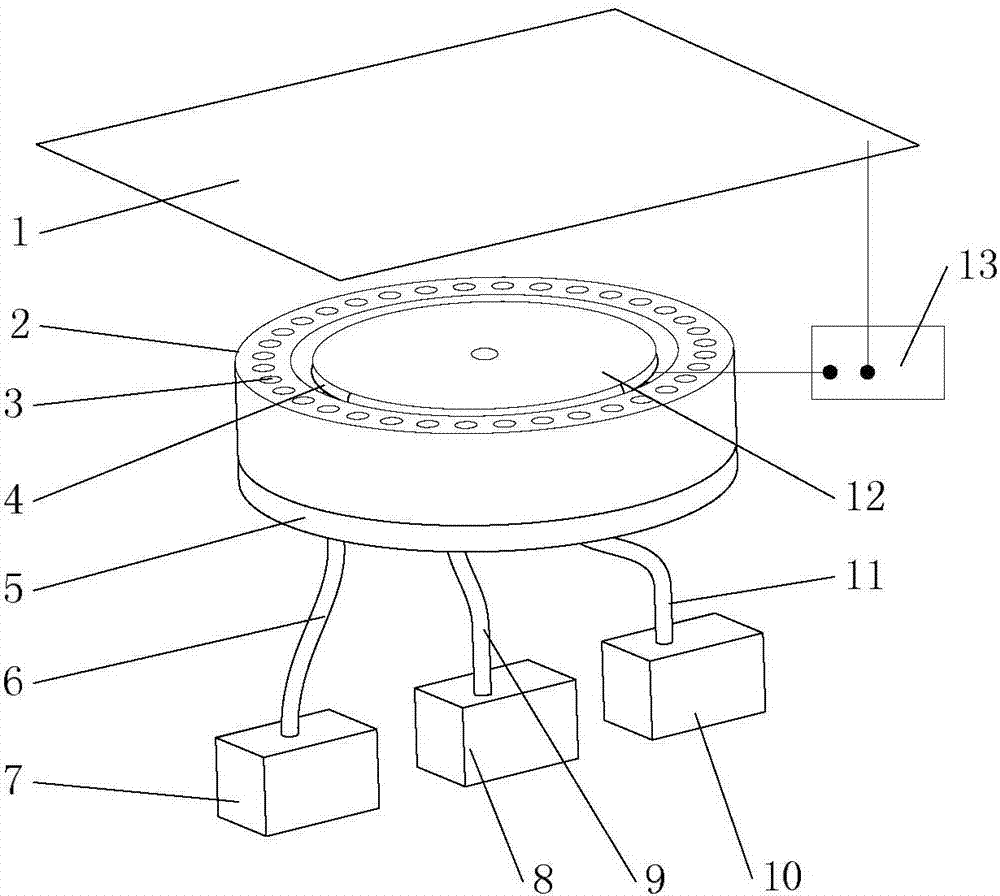

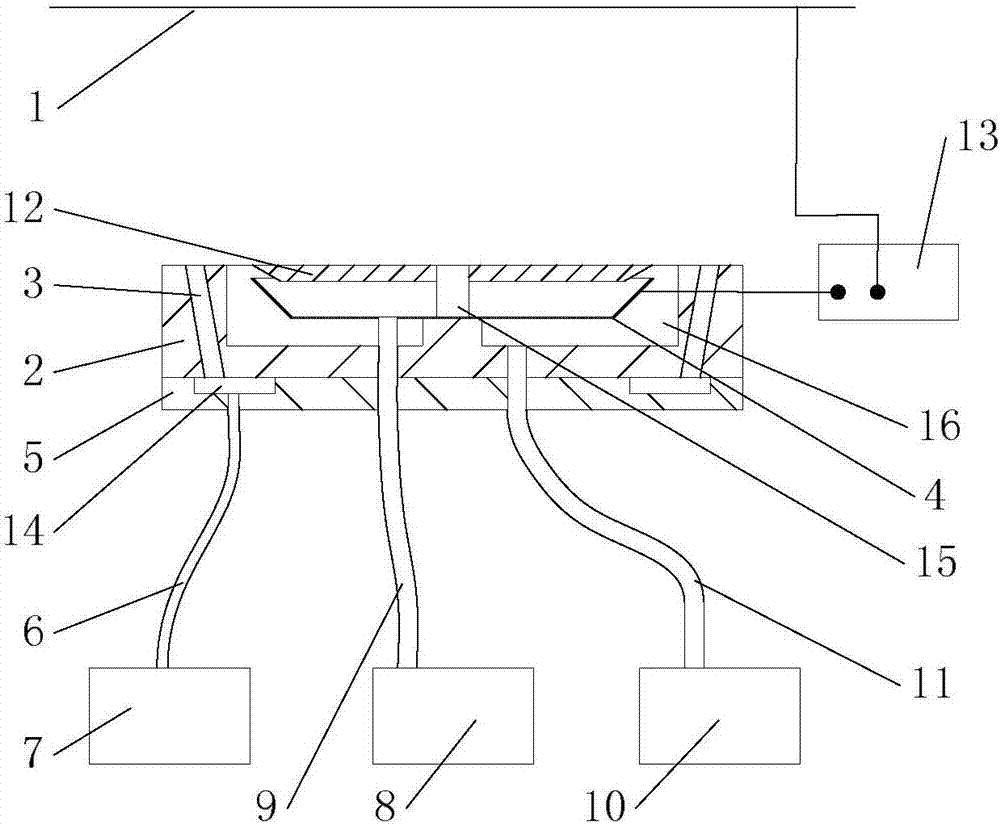

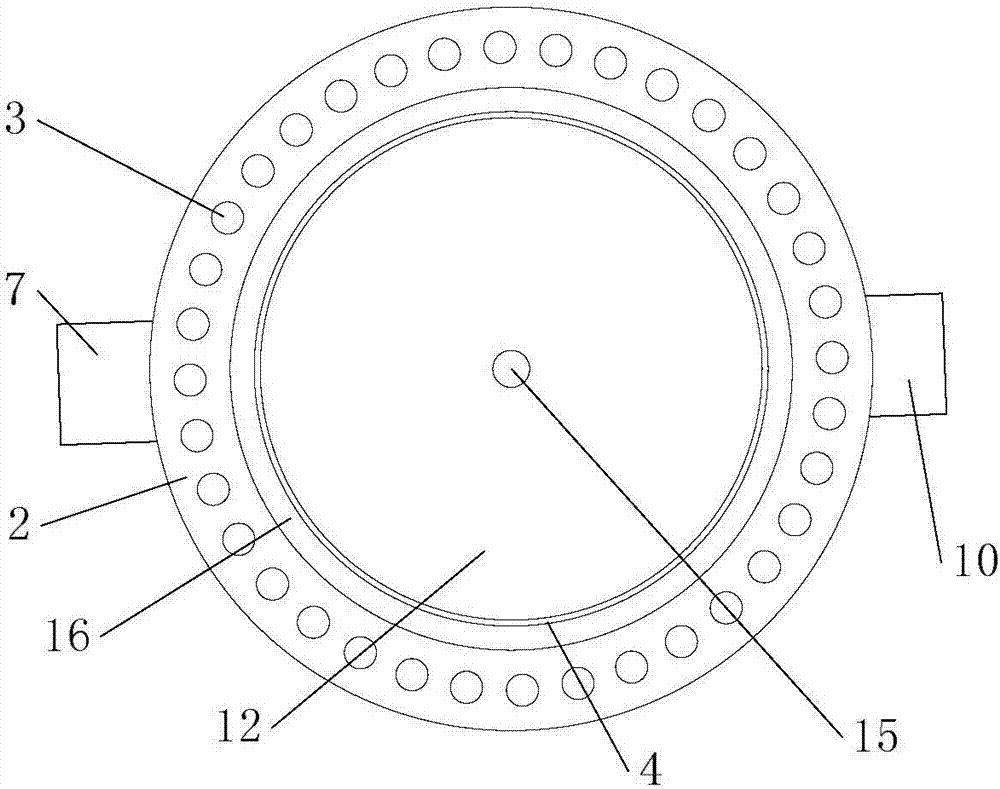

[0027] The structure of a disk-shaped electrode electrospinning device of the present invention will be described below with the help of the embodiments in the accompanying drawings. The disc-shaped electrode electrospinning device includes a spinning system, a gas auxiliary system, a liquid supply system, a collection system, and a high-voltage power supply.

[0028] Such as figure 1 , figure 2 and image 3 As shown, the spinning system includes an upper cover 2 , a spinning electrode 4 , a lower cover 5 , a disc cover 12 and a guide post 15 . The spinning electrode 4, the disk cover 12 and the guide post 15 are arranged on the upper cover 2, and the upper cover 2 and the lower cover 5 are connected by fasteners to form a whole or the upper cover 2 and the lower cover 5 are integrally formed. As the base of the spinning system. The spinning electrode 4 is made of conductive material and is fixedly installed. The spinning electrode 4 is a disk-shaped structure, which can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com