Heat-conducting adhesive and secondary battery containing heat-conducting adhesive

A technology of thermal conductive adhesive and hot melt adhesive, applied in the field of lithium ion batteries, can solve problems such as insufficient adhesion and poor thermal conductivity, achieve good thermal conductivity and improve overcharge safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] The preparation method of the heat-conducting adhesive of the present application is as follows: in a moisture-free inert gas protection environment, after heating the raw materials, add heat-conducting fillers, stir and disperse evenly, and then seal.

[0067] The present application also relates to the use of the heat-conducting adhesive. The heat-conducting adhesive of the present application can be used in secondary batteries, suitable for any position in the secondary battery that needs to be bonded, and is preferably installed between the battery cell and the safety component. Among them, the safety components include circuit breakers, PTC (Positive Temperature Coefficient) and fuses.

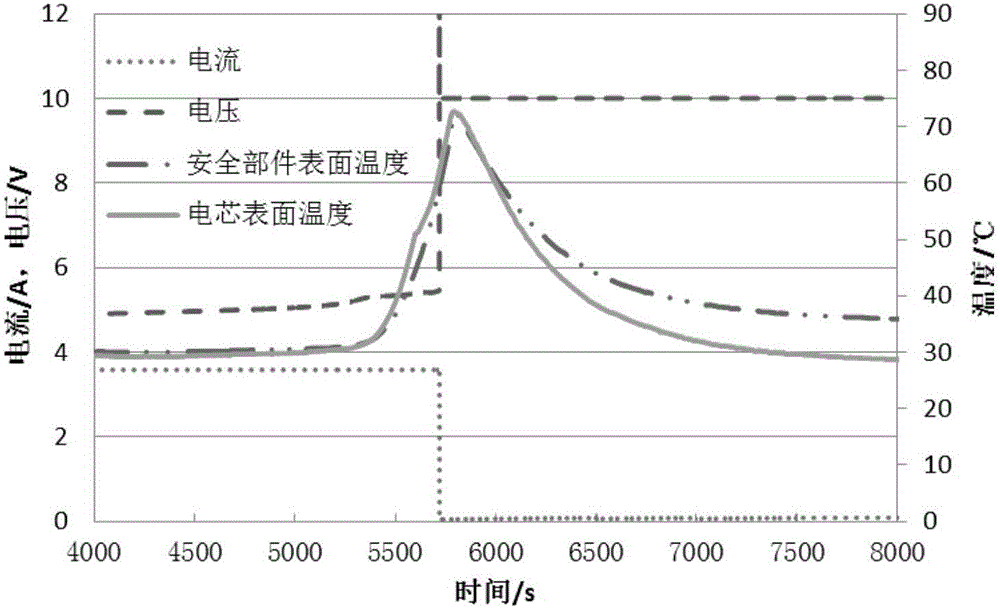

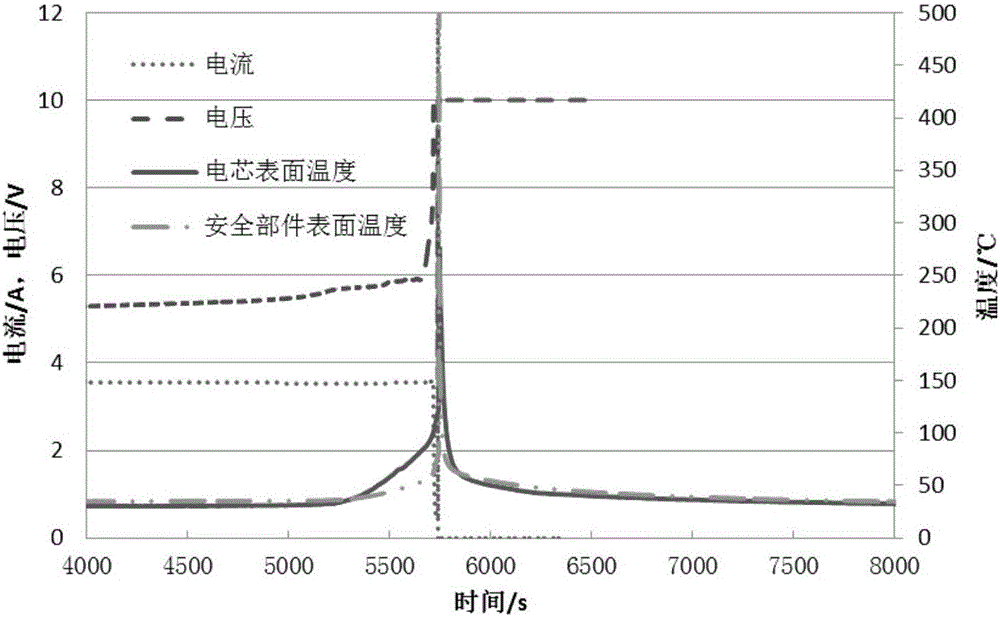

[0068] The present application also relates to a secondary battery, comprising a battery cell, a safety component fixed on the battery cell, and a thermally conductive glue between the battery cell and the safety component, wherein the thermally conductive glue is the thermally cond...

Embodiment 1~9

[0077] Prepare a thermally conductive adhesive according to the hot melt adhesive and thermally conductive filler shown in Table 1, and apply the prepared thermally conductive adhesive between the battery cell and the safety component, and test the performance of the battery cell.

[0078] Preparation method of heat-conducting adhesive: In a moisture-free inert gas protection environment, heat the raw materials, add heat-conducting fillers, stir and disperse evenly, and then seal.

[0079] The preparation method of the battery: apply heat-conducting glue on the safety component, or apply heat-conducting glue on the battery cell, and apply a pressure of 0.1-100N to make the safety component and the battery cell bond firmly; the operating temperature of the heat-conducting glue is 150-200°C.

[0080] Table 1:

[0081]

[0082] The detection method is:

[0083] (1) Initial adhesion test method: Prepare samples with 0.03mg / mm glue drop, cut 3mm×20mm samples, stick TCO after gl...

Embodiment 2

[0093] Prepare a thermally conductive adhesive according to the hot melt adhesive and thermally conductive filler shown in Table 4, and apply the prepared thermally conductive adhesive between the battery cell and the safety component, and test the performance of the battery cell. The preparation method is the same as in Example 1.

[0094] Table 4:

[0095]

[0096]

[0097] The properties of the thermally conductive adhesives of Examples 10 to 26 and the batteries prepared using the thermally conductive adhesive are shown in Table 5 and Table 6:

[0098] table 5:

[0099]

[0100] Table 6:

[0101]

[0102]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com