Luminous 3D printing photosensitive adhesive and preparation method thereof

A 3D printing and photosensitive adhesive technology, which is applied in the direction of luminous coatings, coatings, polyurea/polyurethane coatings, etc., can solve the problems of poor functionality, heating, inconvenient use, etc., and achieve fast curing speed, simple process and mature technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

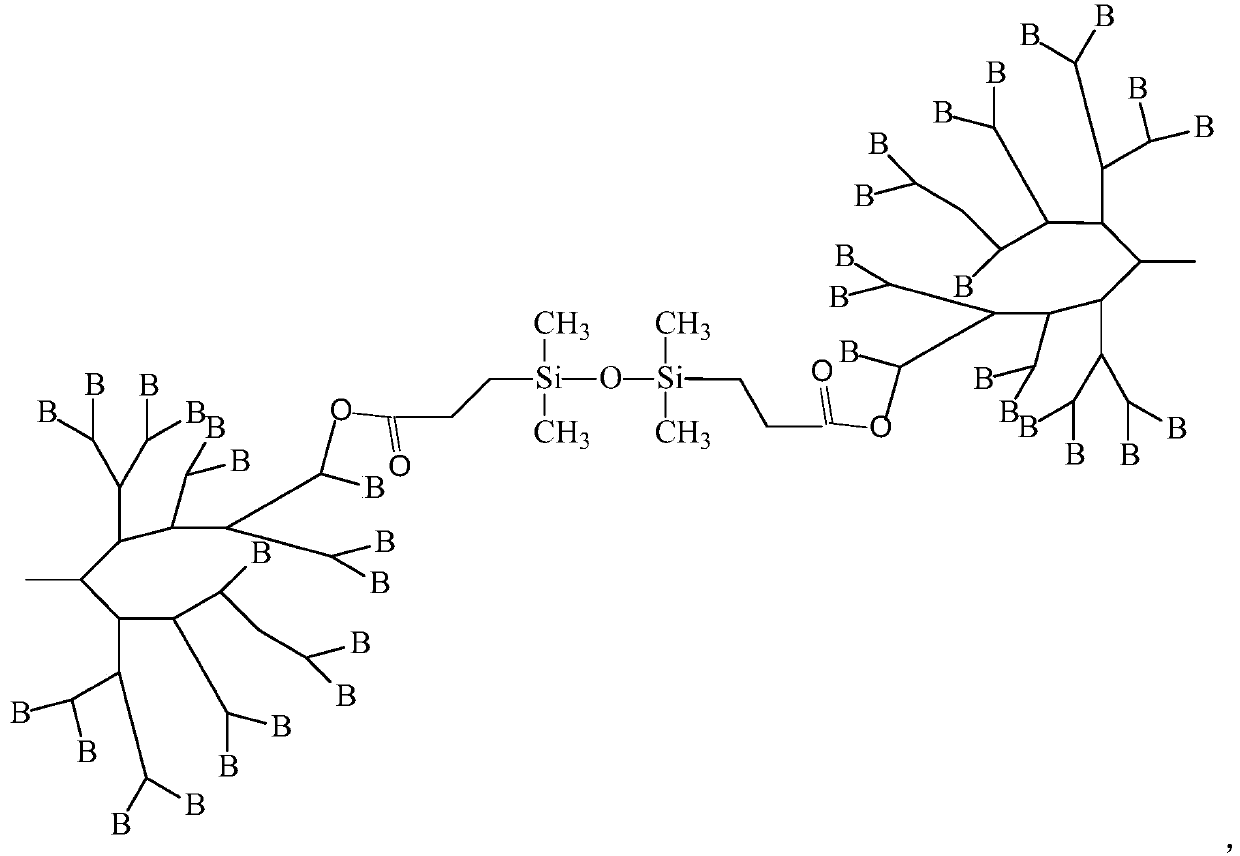

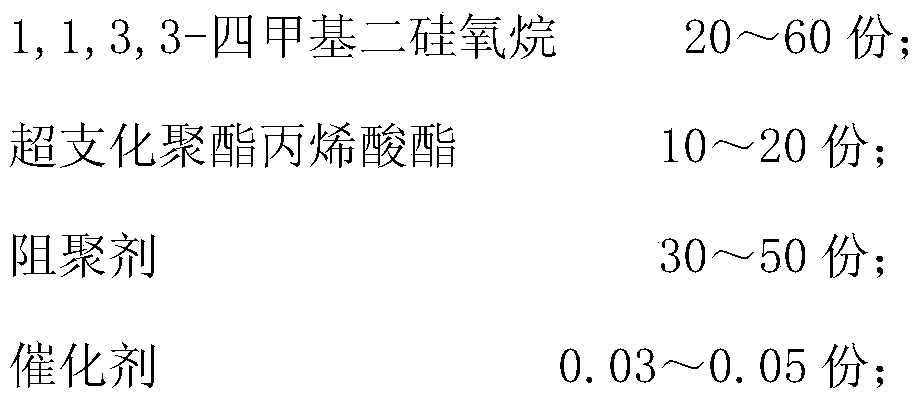

[0040]A luminous 3D printing photosensitive adhesive, calculated in parts by weight, its raw material composition and content are as follows:

[0041]

[0042] Wherein said UV curable resin A is prepared according to the following method:

[0043] Add 10g of 1,1,3,3-tetramethyldisiloxane and 10g of hyperbranched polyester acrylate into a 500ml three-necked flask, then add 0.01g of hydroquinone, pass through protective gas, stir and heat, Raise the temperature to 60°C, add 0.01g of chloroplatinic acid complex, keep stirring for 3 hours, stop heating, and wait until the temperature of the flask drops to room temperature to obtain UV-curable resin A.

[0044] Described UV curing resin B is a toughening resin, such as a mixture of epoxy acrylate and polyurethane acrylate in a mass ratio of 1:1;

[0045] The leveling agent is Tego Glide 410;

[0046] Described UV wetting agent is NP-100 of U.S. Dow Company;

[0047] The said luminous powder is the yellow-green MG-1 provided b...

Embodiment 2

[0056] A luminous 3D printing photosensitive adhesive, calculated in parts by weight, its raw material composition and content are as follows:

[0057]

[0058] Wherein said UV curable resin A is prepared according to the following method:

[0059] Add 10g of 1,1,3,3-tetramethyldisiloxane and 10g of hyperbranched polyester acrylate into a 500ml three-necked flask, then add 0.01g of hydroquinone, pass through protective gas, stir and heat, Raise the temperature to 60°C, add 0.01g of chloroplatinic acid complex, keep stirring for 3 hours, stop heating, and wait until the temperature of the flask drops to room temperature to obtain UV-curable resin A.

[0060] Described UV curing resin B is a toughening resin, such as a mixture of epoxy acrylate and polyurethane acrylate in a mass ratio of 2:1;

[0061] The leveling agent is a mixture of German BYK-345 and BYK-346 in a mass ratio of 1:1;

[0062] The UV wetting agent is German BYK 333;

[0063] The defoamer is a mixture of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com