Integrated integrated bathroom chassis and preparation method of the chassis body

A technology of chassis and body, applied in the field of bathroom, can solve the problems of poor waterproof effect of bathroom chassis and restrictions on the popularization of the whole bathroom, and achieve the effects of avoiding blockage, not easily deformed, and increasing structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings, so that those of ordinary skill in the art can implement it after referring to this specification.

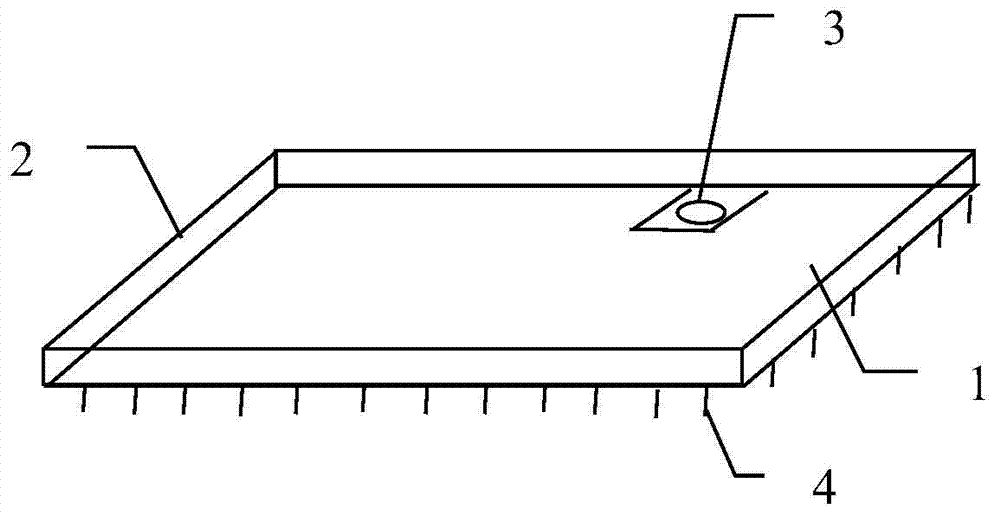

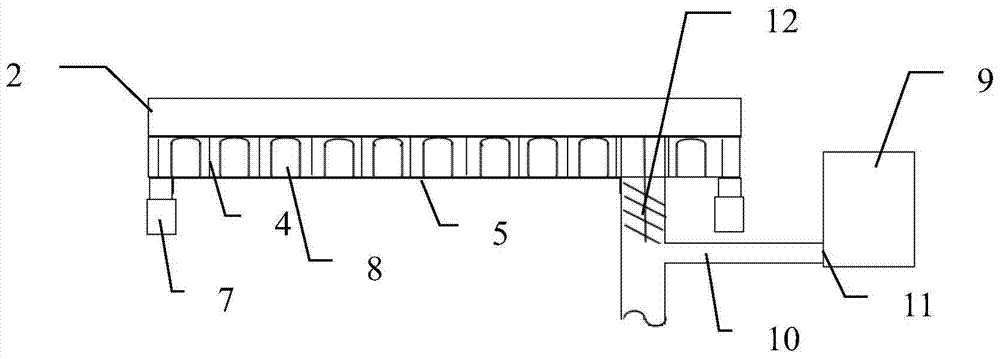

[0030] Such as figure 1 , 2 As shown, an integrated integrated bathroom chassis includes: a chassis body 1, which is an integrated chassis molded by using a moldless multi-point molding technology, and the edge of the chassis body 1 is rolled up to form an integrated enclosure 2; The drain hole 3 is integrally opened on the chassis body 1 . The invention molds the SMC composite material by using the moldless multi-point molding technology, and can conveniently adjust the mold according to the shape and size of the overall bathroom chassis, so that the same mold can be molded out of different specifications after simple adjustment. The integrated bathroom chassis overcomes the disadvantages of traditional molding technology that the mold is difficult to adjust and can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com