A continuous flexible incremental forming processing device and method for sheet metal

A technology of incremental forming and processing devices, applied in feeding devices, positioning devices, metal processing equipment, etc., can solve the problems of low efficiency, wasting time, inconvenient to take, etc., to increase the clamping area and reduce the deformation of the plate , to achieve the effect of cutting separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

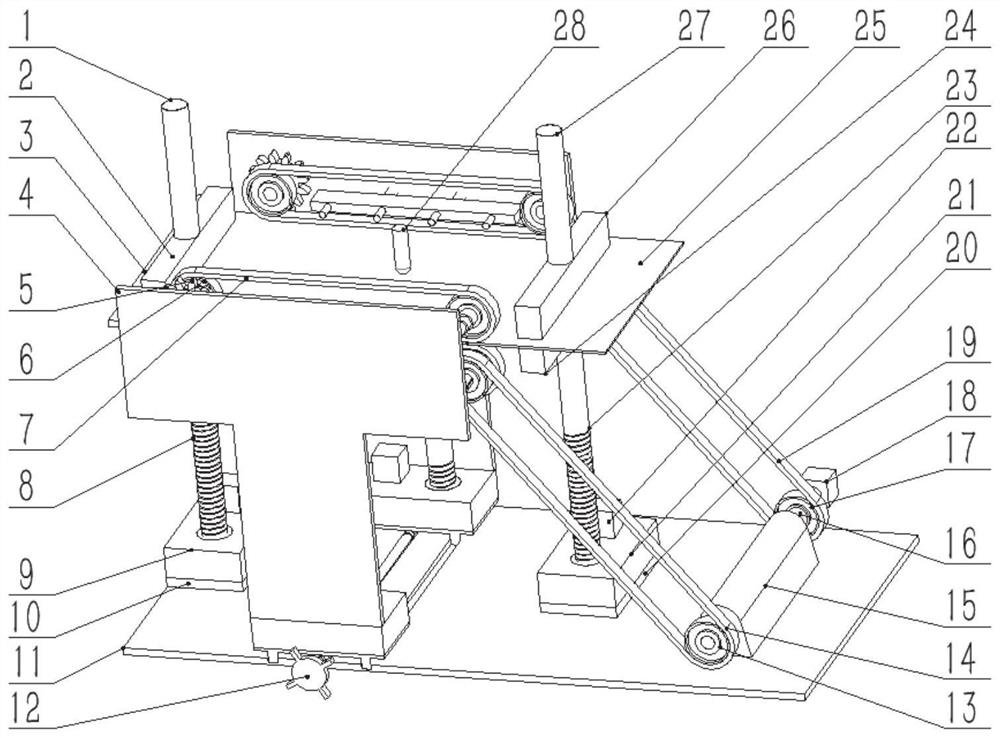

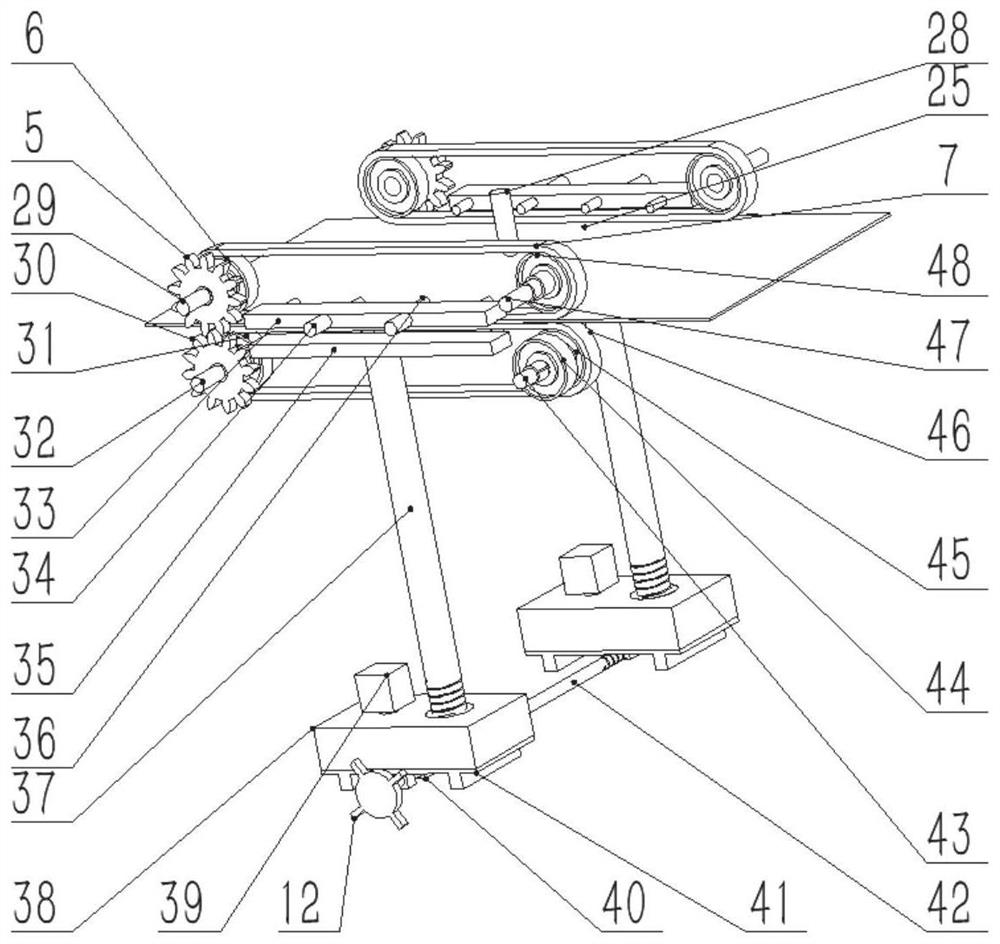

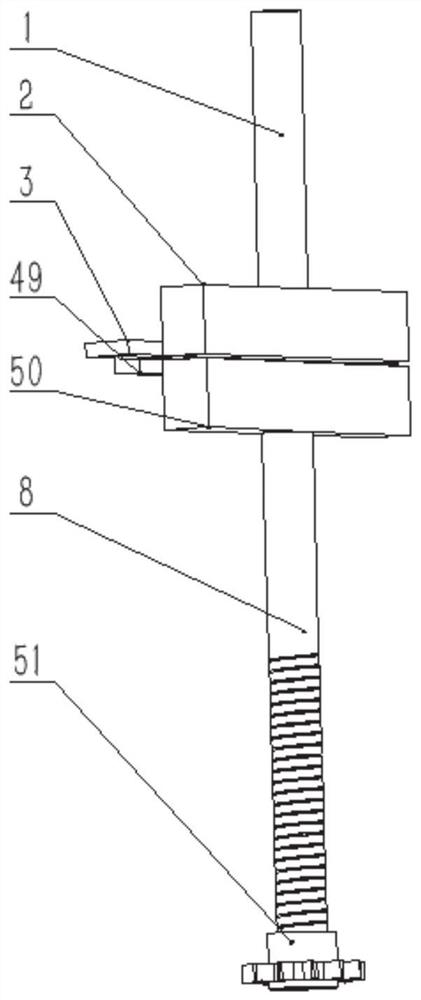

[0049] This embodiment provides a continuous flexible incremental forming processing device for plates, such as Figure 1-Figure 7 As shown, it includes a cutter 28, a clamping device, a conveying device, a vertical adjustment device, a longitudinal adjustment device and a cutting device. The cutter 28 is connected with a numerical control machine tool to realize continuous progressive forming of the plate 25. The plate 25 is reliably clamped through four clamping devices, front, rear, left, right, and transmission devices. The position of the clamping device is adjusted by a vertical adjustment device to meet the clamping requirements of plates 25 of different thicknesses. The front and rear clamping devices and the transmission device The longitudinal position can be adjusted by the longitudinal adjustment device to meet the processing requirements of plates 25 of different widths.

[0050] Such as figure 1 and figure 2 As shown, the longitudinal adjustment device is comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com