Core-pulling cooling device for die-casting die

A technology of cooling device and die-casting mold, applied in the field of mold core-pulling structure, can solve the problems of poor cooling effect at the core-pulling position, inconvenient core-pulling operation, complex structure, etc., so as to avoid local overheating, good cooling effect, The effect of core pulling is easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

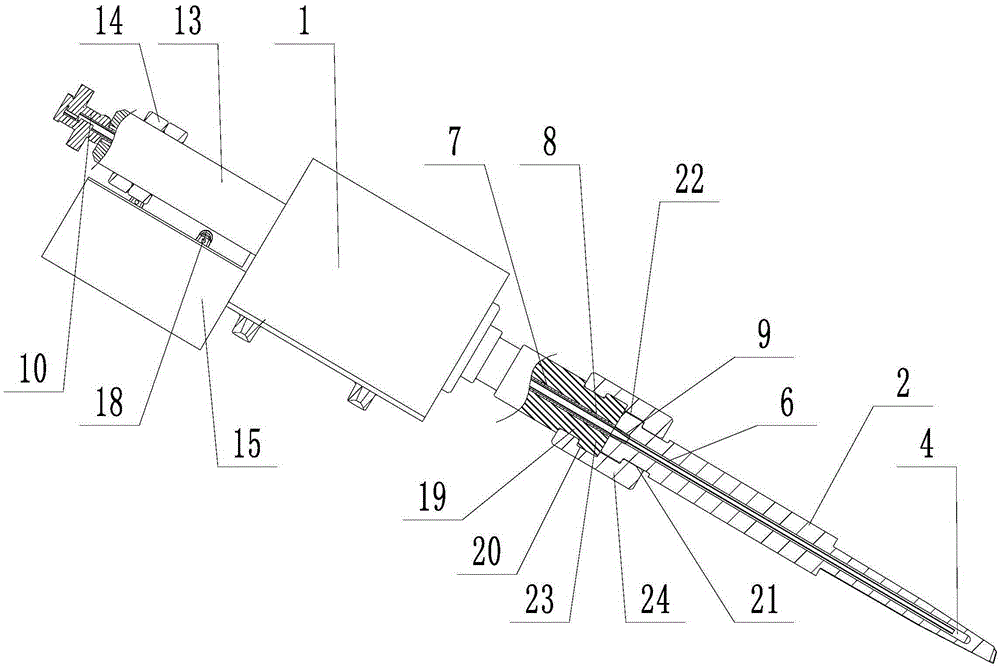

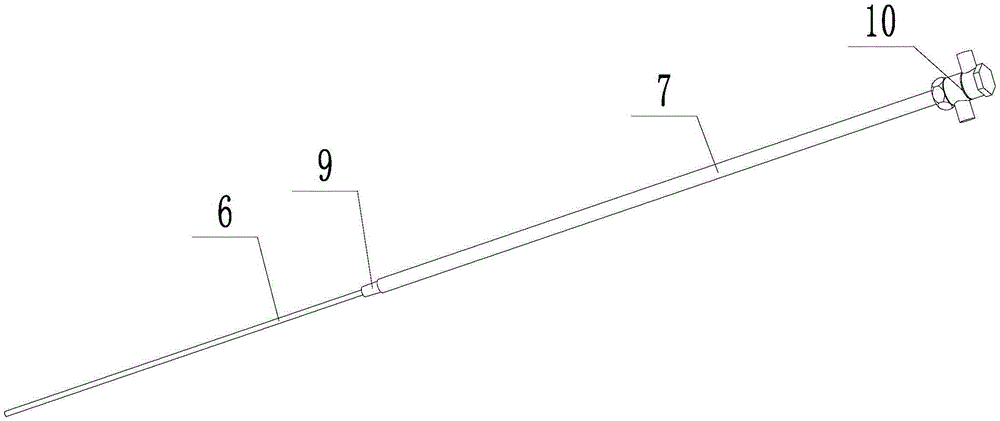

[0020] Embodiment: A kind of die-casting mold core-pulling cooling device (see attached Figures 1 to 4 ), including a piston cylinder 1, a core 2, and a cooling pipe 3. There is a cooling cavity 4 arranged along the axis in the core, and the bottom of the cooling cavity is close to the front end of the core. Transition block 5, the cooling pipe is movably connected to the piston cylinder, the cooling pipe includes an inner pipe 6 and an outer pipe 7, a liquid return gap 8 is provided between the outer wall of the inner pipe and the inner wall of the outer pipe, the inner pipe extends out of the front end of the outer pipe, and the inner pipe extends The part of the front end of the outer pipe is arranged in the cooling chamber, the front end of the inner pipe is arranged close to the bottom of the cooling chamber, the front end of the outer pipe is provided with a connecting part 9, the open end of the core and the quick release transition block is closely connected with the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com