Tobacco curing barn with diversion structure

A technology of flue-cured tobacco room and deflector, which is applied in the fields of tobacco, tobacco preparation, application, etc. It can solve the problems of affecting the quality of tobacco curing, uneven color quality of tobacco leaves, and uneven air flow, and achieves easy popularization and use, simple structure, and air flow. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the invention is further introduced:

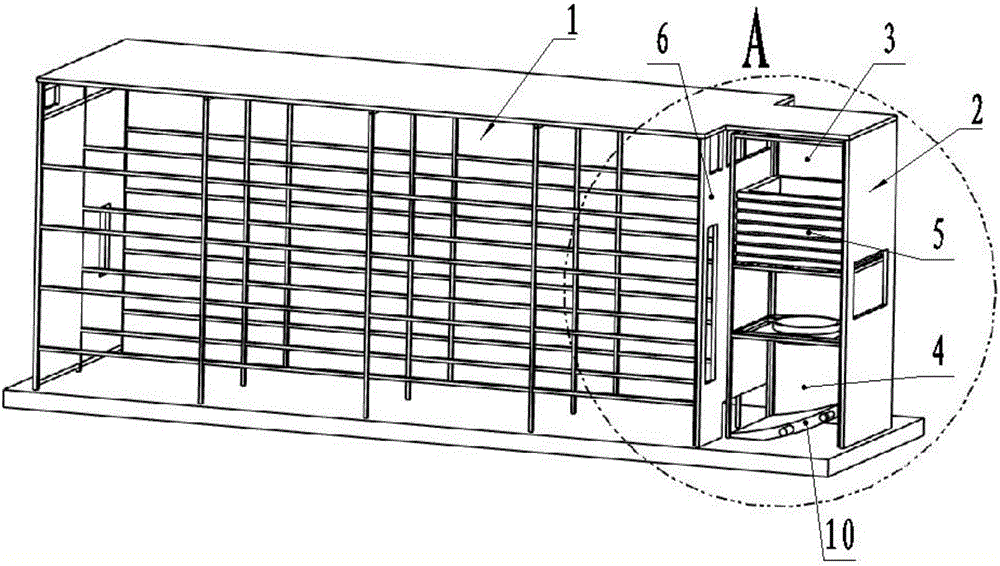

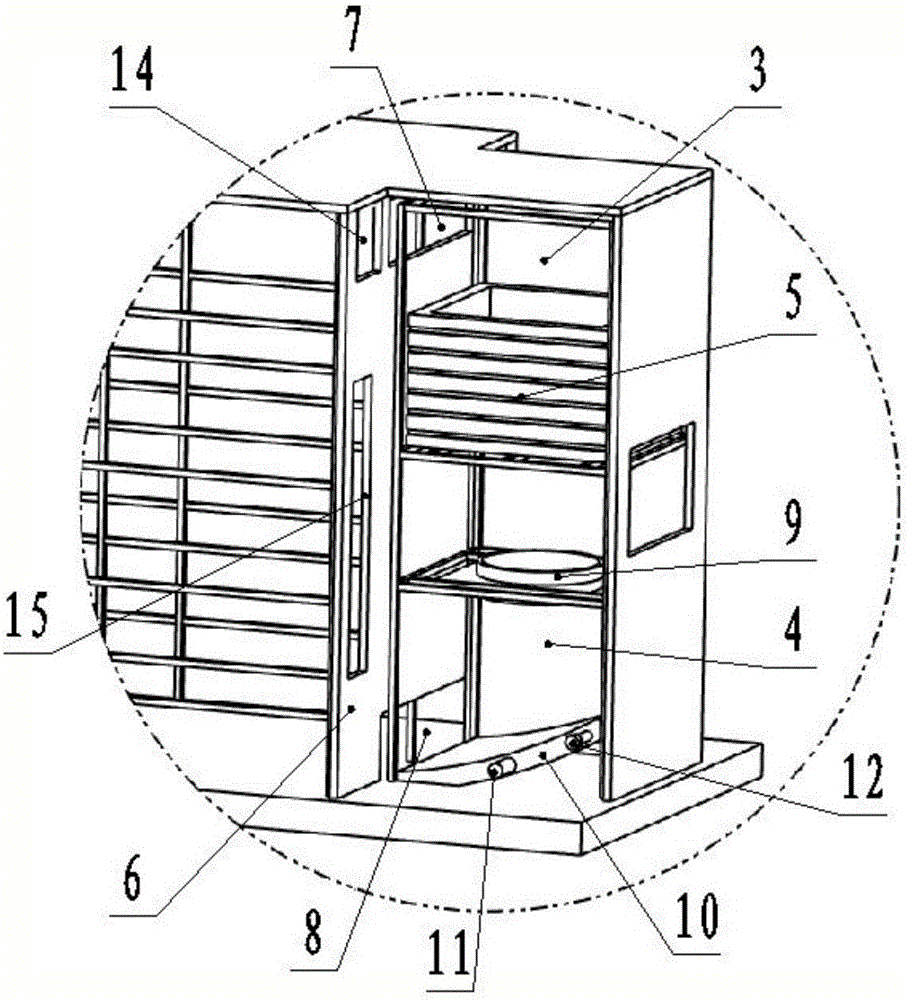

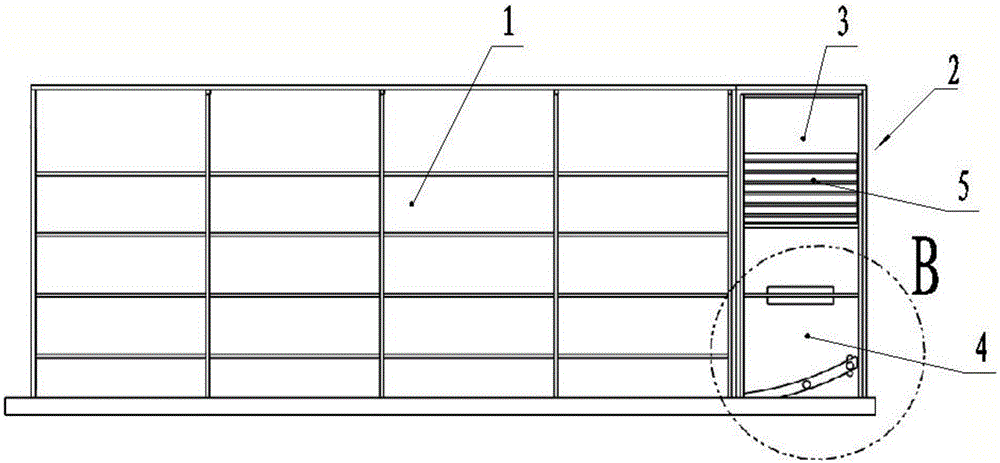

[0022] A tobacco flue-curing room with a diversion structure, comprising a tobacco loading room 1 and a heating room 2 arranged at the front end of the tobacco loading room 1, and a tobacco leaf display rack composed of a horizontal bar and a vertical bar is arranged inside the tobacco loading room 1 for Arrange the tobacco leaves.

[0023] The heating chamber 2 is provided with an upper chamber 3 and a lower chamber 4, and a heating device 5 is arranged in the upper chamber 3. The smoke chamber 1 and the heating chamber 2 are separated by a heat insulating wall 6, and the heat insulation The upper part of the wall 6 is provided with a return air outlet 7 connected to the smoke chamber 1 and the upper chamber 3, and the lower part of the heat insulation wall 6 is provided with an air supply port 8 connected to the smoke chamber 1 and the lower chamber 4, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com