Preparation method of colorful crisp potato chips through osmotic dehydration and vacuum freeze-drying

A color potato, osmotic dehydration technology, applied in food drying, function of food ingredients, food science and other directions, can solve the problems affecting the appearance and flavor of fruit and vegetable chips, loss of nutrients in fruit and vegetable chips, and low market competitiveness of fruit and vegetable chips, etc. problems, to prevent cardiovascular disease, increase economic added value, and achieve good color and shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

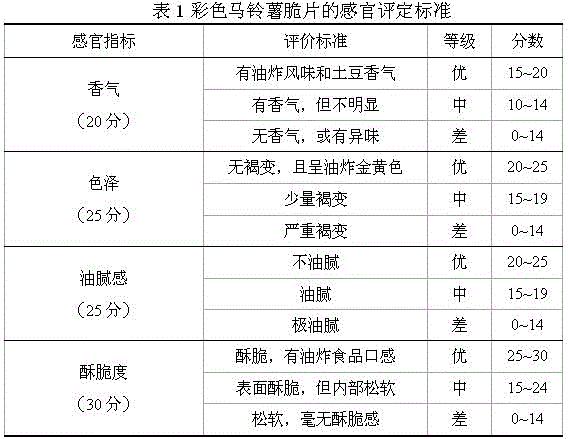

Image

Examples

Embodiment 1

[0015] Embodiment 1 of the present invention: the preparation method of osmotic dehydration-vacuum freeze-dried colored potato crisps comprises the following steps:

[0016] 1) Raw material pretreatment: Wash and peel fresh colored potatoes, and put them in clean water for later use;

[0017] 2) Slicing: Cut the peeled colored potatoes into potato slices with a thickness of 5mm;

[0018] 3) Color protection: Soak the cut potato slices in the color protection solution for 20 minutes; the color protection solution includes 0.5% NaCl, 0.15% citric acid, 0.08% Vc and 0.02% L-halogen Cystine, the rest is water;

[0019] 4) Osmotic dehydration: take out the potato slices in the color protection solution, immerse in sucrose aqueous solution with a mass concentration of 65% for osmotic dehydration for 2 hours; ℃, the solid-to-liquid ratio of the input potato chips to the sucrose aqueous solution is 1:8, and the unit is g / ml.

[0020] 5) Pre-freezing: take out the potato slices in t...

Embodiment 2

[0022] Embodiment 2 of the present invention: the preparation method of osmotic dehydration-vacuum freeze-dried colored potato chips, comprising the following steps:

[0023] 1) Raw material pretreatment: Wash and peel fresh colored potatoes, and put them in clean water for later use;

[0024] 2) Slicing: Cut the peeled colored potatoes into potato slices with a thickness of 6mm;

[0025] 3) Color protection: soak the cut potato slices in the color protection solution for 25 minutes; the color protection solution includes 0.5% NaCl, 0.15% citric acid, 0.08% Vc and 0.02% L-semi Cystine, the rest is water;

[0026] 4) Osmotic dehydration: take out the potato slices in the color protection solution, immerse in 60% sucrose aqueous solution for osmotic dehydration for 1.5h; At 35°C, the solid-to-liquid ratio of the input potato chips to the sucrose aqueous solution is 1:10, and the unit is g / ml.

[0027] 5) Pre-freezing: Take out the potato slices in the sucrose aqueous solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com