Crispy cereal biscuits and making method thereof

A technology of crispy biscuits and grains, applied in the fields of grainy crispy biscuits and their preparation, and biscuits, can solve the problems of insufficient dietary fiber content, high fat content, high fat content, etc., and achieve the prevention and treatment of cardiovascular sclerosis, sugar-containing Effect of lowering and controlling blood sugar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

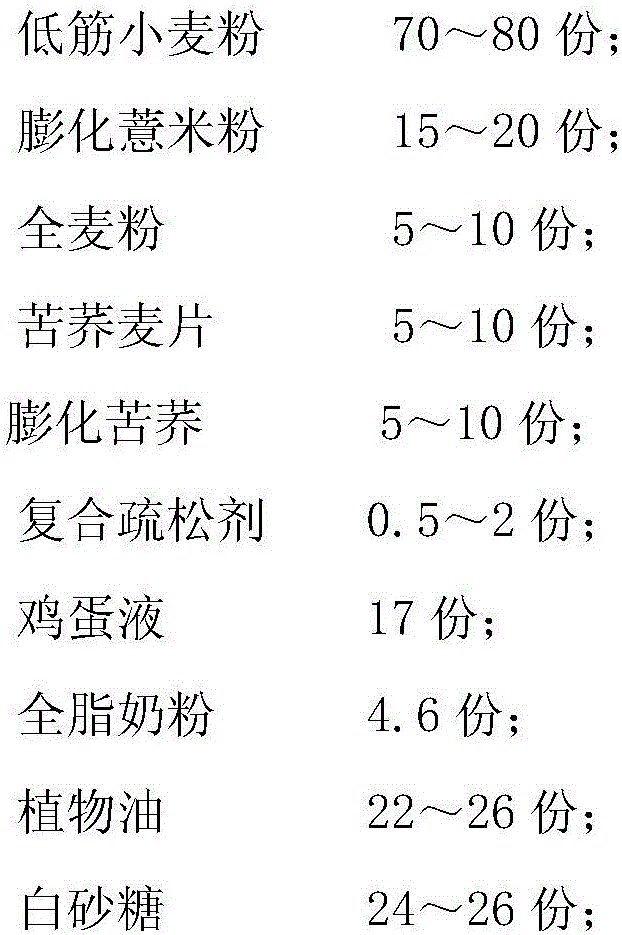

[0068] A grain crisp biscuit, calculated according to the weight of dry powder, its raw material composition and content are as follows:

[0069]

[0070] The composite loosening agent is calculated by weight ratio and is formed by compounding sodium bicarbonate: ammonium bicarbonate: glucono-δ-lactone: citric acid: starch=3:4:3:2:1

[0071] The specifications of the low-gluten wheat flour meet the national standard GB / T8607-1988;

[0072] All the above-mentioned raw materials are powdery solids with good fluidity, and all pass the CQ20 sieve stipulated in the national standard GB5507;

[0073] The preparation method of above-mentioned puffed barley flour and puffed tartary buckwheat is as follows:

[0074] (1) Preparation of puffed barley powder

[0075] Select barley grains with full grains, add water, the mass ratio of barley grains to water is 1:0.04, after mixing evenly, air-jet puffing at 250°C for 25s, and pulverize the puffed barley with a flour mill, pass 100 Me...

Embodiment 2

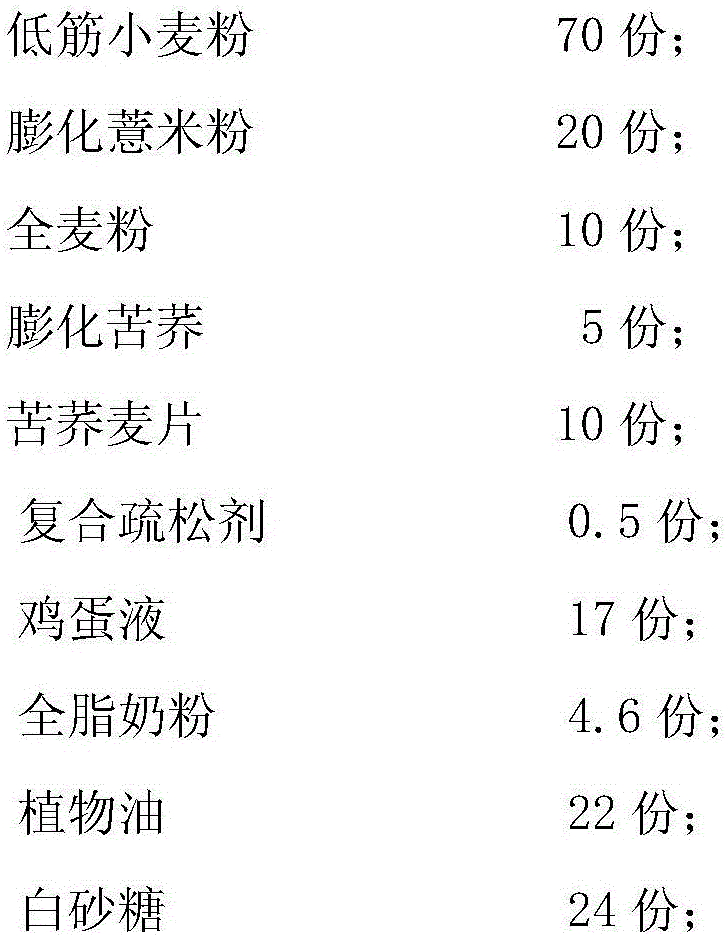

[0094] A grain crisp biscuit, calculated according to the weight of dry powder, its raw material composition and content are as follows:

[0095]

[0096]

[0097] The composite loosening agent is calculated by weight ratio and is formed by compounding sodium bicarbonate: ammonium bicarbonate: glucono-δ-lactone: citric acid: starch=3:4:3:2:1

[0098] The specifications of the low-gluten wheat flour meet the national standard GB / T8607-1988;

[0099] All the above-mentioned raw materials are powdery solids with good fluidity, and all pass the CQ20 sieve stipulated in the national standard GB5507;

[0100] The preparation method of above-mentioned puffed barley flour and puffed tartary buckwheat is as follows:

[0101] (1) Preparation of puffed barley powder

[0102] Select barley grains with full grains, add water at a ratio of 1:0.04, mix evenly, and air-jet puff them at 250°C for 25 seconds, crush the puffed barley with a flour mill, and pass through a 100-mesh sieve t...

Embodiment 3

[0122] A grain crisp biscuit, calculated according to the weight of dry powder, its raw material composition and content are as follows:

[0123]

[0124]

[0125] The composite loosening agent is calculated by weight ratio and is formed by compounding sodium bicarbonate: ammonium bicarbonate: glucono-δ-lactone: citric acid: starch=3:4:3:2:1

[0126] The specifications of the low-gluten wheat flour meet the national standard GB / T8607-1988;

[0127] All the above-mentioned raw materials are powdery solids with good fluidity, and all pass the CQ20 sieve stipulated in the national standard GB5507;

[0128] The preparation method of above-mentioned puffed barley flour and puffed tartary buckwheat is as follows:

[0129] (1) Preparation of puffed barley powder

[0130] Select barley grains with full grains, add water at a ratio of 1:0.04, mix evenly, and air-jet puff them at 250°C for 25 seconds, crush the puffed barley with a flour mill, and pass through a 100-mesh sieve t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com