A controllable atmosphere protection device for laser rapid forming of titanium alloy parts

A laser rapid prototyping and protection device technology, which is applied in packaging under vacuum/special atmosphere, laser welding equipment, packaging objects under special gas conditions, etc., can solve the problem of high operation and maintenance costs, high performance requirements of vacuum pumps, and vacuum cycle Long and other problems, to achieve the effect of low manufacturing and maintenance costs, convenient and flexible observation and operation, and shortened pumping and filling cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings.

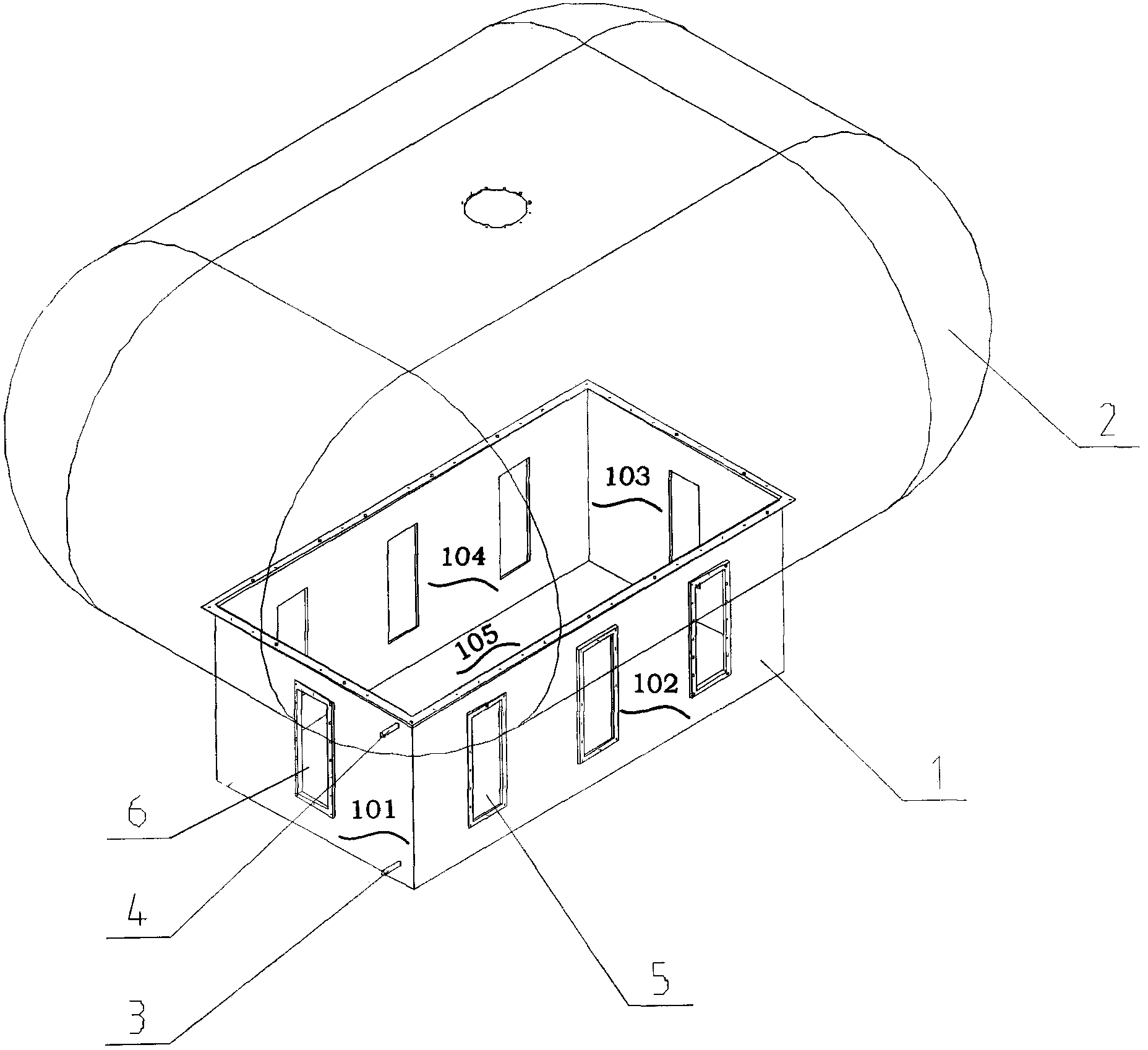

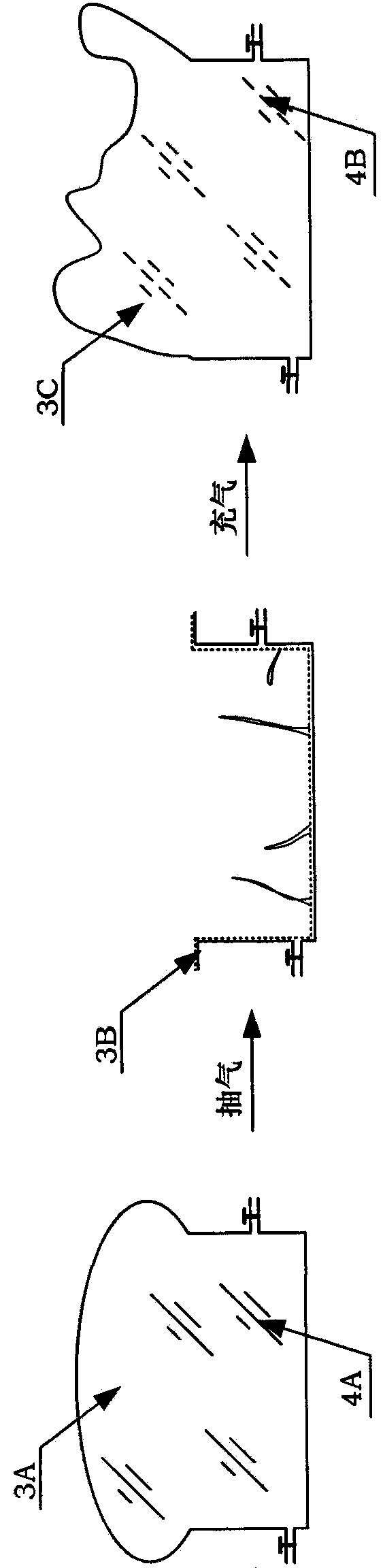

[0019] The present invention provides a controllable atmosphere protective chamber device for laser rapid prototyping of large titanium alloy parts. The device is composed of a rigid sealed box 1 and a flexible bladder-type sealing cover 2. The opening end of the flexible bladder-type sealing cover 2 is connected to the The opening ends of the rigid sealed box 1 are hermetically connected together, and the inner space formed by the connection of the flexible bladder type sealing cover 2 and the rigid sealed box 1 is called the original cavity environment 3A.

[0020] Rigid sealed casing 1 comprises A plate surface 101, B plate surface 102, C plate surface 103, D plate surface 104 and base plate surface 105 (as figure 1 shown).

[0021] The A board surface 101 is provided with an access door 6, an A interface 3, and a B interface 4. The A interface 3 is used...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com