A method for optical visualization of two-dimensional atomic crystal materials on substrate surfaces

A two-dimensional atomic crystal, substrate surface technology, applied to two-dimensional atomic crystal materials, directly observed under a magnifying glass or even with the naked eye, graphene in the field of ordinary optical microscope, can solve the problem of inability to remove, affect graphene measurement and application, pollution Graphene surface and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1, using water vapor to assist the optical visualization of graphene on a copper substrate

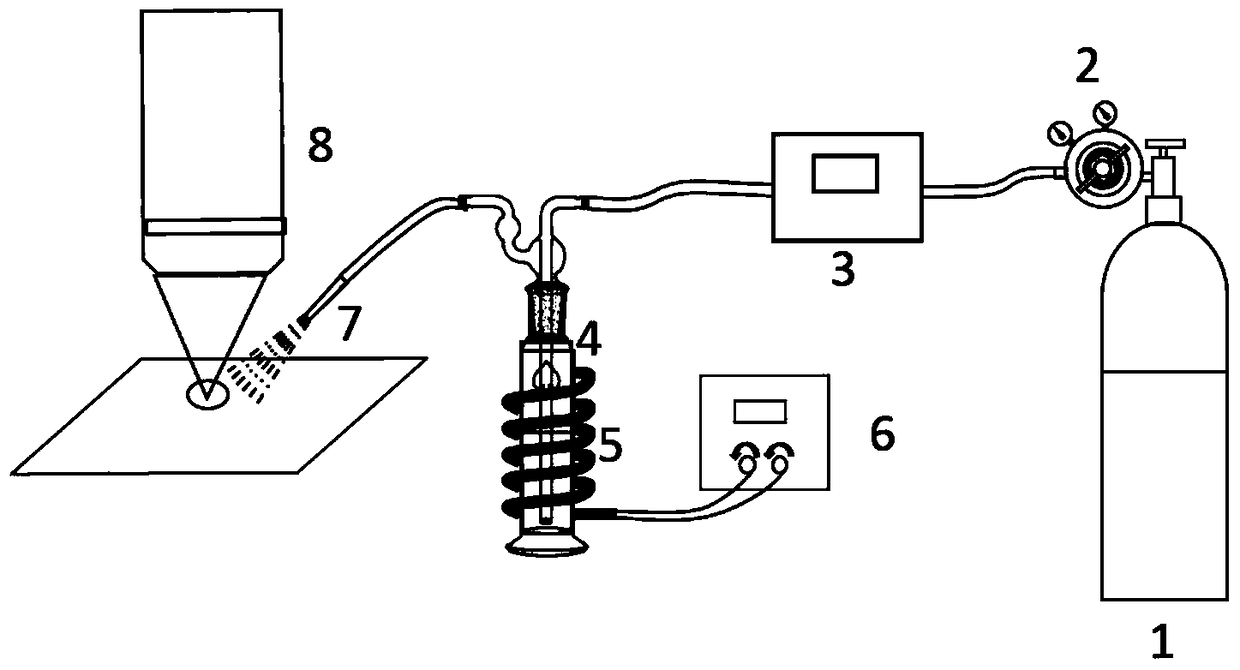

[0028] Specific observation devices such as figure 1 As shown, first adjust the voltage source voltage to 100V, heat the water in the container through the heating belt, when the water is heated to warm water, reduce the power supply voltage to 50V and keep it, then adjust the pressure reducing valve to release argon and adjust the gas flowmeter to At 200sccm, argon gas enters the container, bringing out water vapor and ejecting it from the nozzle. Place the sample on the stage of the microscope. When the water vapor is sprayed on the surface of the sample, the water vapor will condense into water droplets and be observed directly through the microscope.

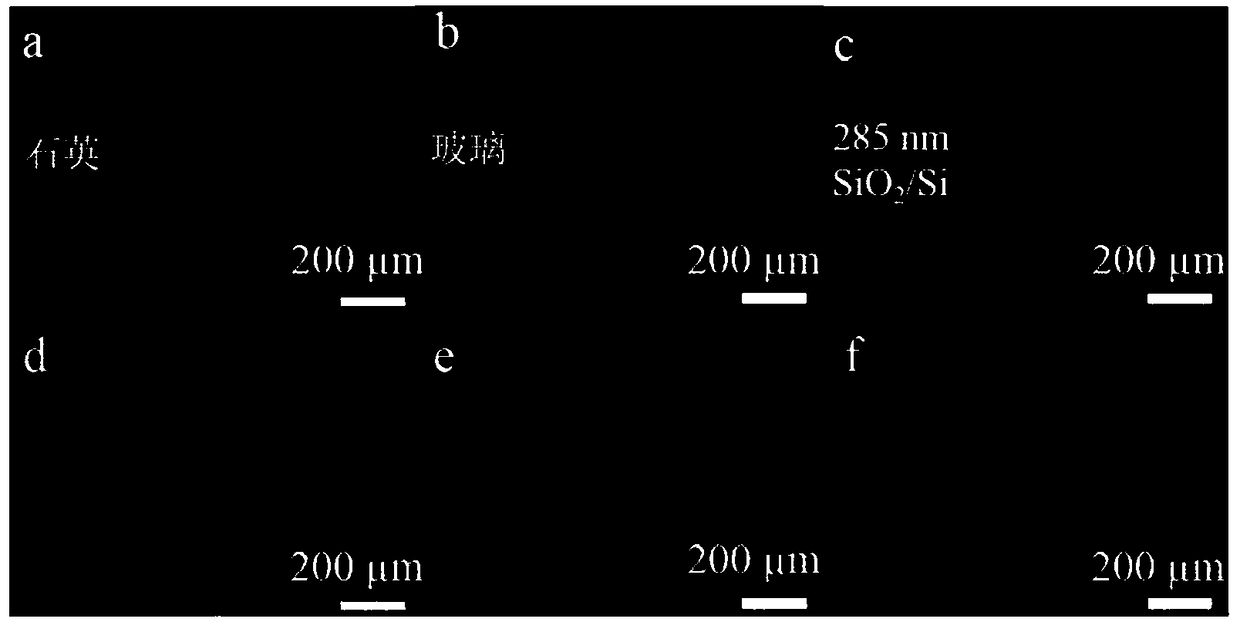

[0029] In this embodiment, the optical photographs before and after water vapor spraying on the copper substrate surface with graphene are as follows: figure 2 As shown, the differences in morphology, density, an...

Embodiment 2

[0032] Embodiment 2, using water vapor to assist in realizing the optical visualization of graphene on a quartz substrate

[0033] The specific observation device is the same as in Example 1. First, the graphene is transferred to the surface of the quartz substrate, the voltage source is adjusted to 100V, and the water in the container is heated by the heating belt. When heated to warm water, the power supply voltage is reduced to 50V and maintained. Then adjust the pressure reducing valve to release the argon and adjust the gas flow meter to 200 sccm, the argon enters the container, brings out the water vapor and sprays it out from the nozzle. The quartz substrate transferred with graphene is placed on the stage of the microscope in the device. When the water vapor is sprayed on the surface of the sample, the water vapor condenses into water droplets and is directly observed through the microscope.

[0034] In this embodiment, the optical photographs before and after water va...

Embodiment 3

[0036] Embodiment 3, using water vapor to assist in realizing the optical visualization of graphene on a glass substrate

[0037] The specific observation device is the same as in Example 1. First, the graphene is transferred to the surface of the glass substrate, the voltage source is adjusted to 100V, and the water in the container is heated by the heating belt. When heated to warm water, the power supply voltage is reduced to 50V and maintained. Then adjust the pressure reducing valve to release the argon and adjust the gas flow meter to 200 sccm, the argon enters the container, brings out the water vapor and sprays it out from the nozzle. The glass substrate transferred with graphene is placed on the stage of the microscope in the device. When the water vapor is sprayed on the surface of the sample, the water vapor condenses into water droplets and is directly observed through the microscope.

[0038] In the present embodiment, the optical photographs before and after wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com