Method estimating hot-working performance of metal material

A metal material and thermal processing technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve problems such as narrow application range and difficulty in engineering application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0029] The present invention is a method for evaluating the thermal processing performance of metal materials. Below, taking the evaluation of the thermal processing performance of GH4169 alloy (typical metal material) as an example, the specific implementation details of the evaluation method involved in the present invention are introduced in detail. The method includes:

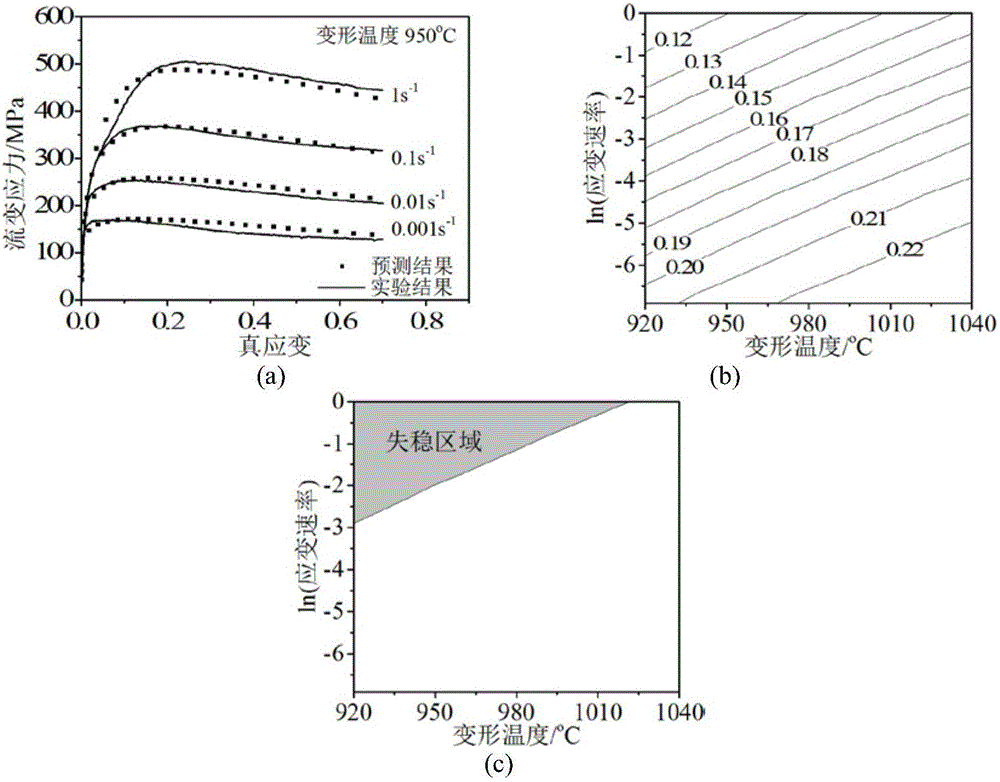

[0030] Step 1: Conduct high-temperature compression experiments on GH4169 alloy, the deformation temperatures are 920°C, 950°C, 980°C, 1010°C and 1040°C, and the strain rates are 0.001s -1 、0.01s -1 , 0.1s -1 and 1s -1 , should be 1.2.

[0031] Step 2: Establish an improved hyperbolic sine constitutive model describing the high-temperature flow stress of GH4169 alloy, and implement it through programming;

[0032] Based on the true stress-true strain data measured by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com