The overall relocation method of transfer machine and belt head in the process of large mining height and small relocation

A technology for reloading machine head and belt head, which is applied in the field of mobile relocation, which can solve the problems of high work intensity, time-consuming and labor-intensive work, and achieve the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] 1. The overall relocation of the reloading machine

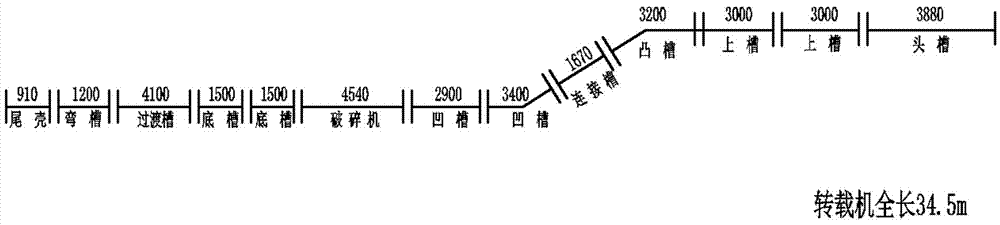

[0026] The model of the reloading machine in the 8206 working face of the 402 panel of Nanshan Well is SZE1000 / 375, that is, the inner diameter of the machine slot is 1000mm, the motor power is 375KW, and the total length is 34.45m. The schematic diagram of its plane size is as follows figure 1 .

[0027] The total length of the loader is 34.5m, and the total mass is nearly 40t. If it is completely disassembled and installed stably, including the motor reducer, it will take 13-15 vehicles to install the loader again. It is not a simple matter. And there is also a belt tail for loading and transportation at the same time. The above-mentioned problems must be solved to ensure that the transfer machine can reach the designated position quickly and safely, so as to ensure the normal production of the fully mechanized mining face.

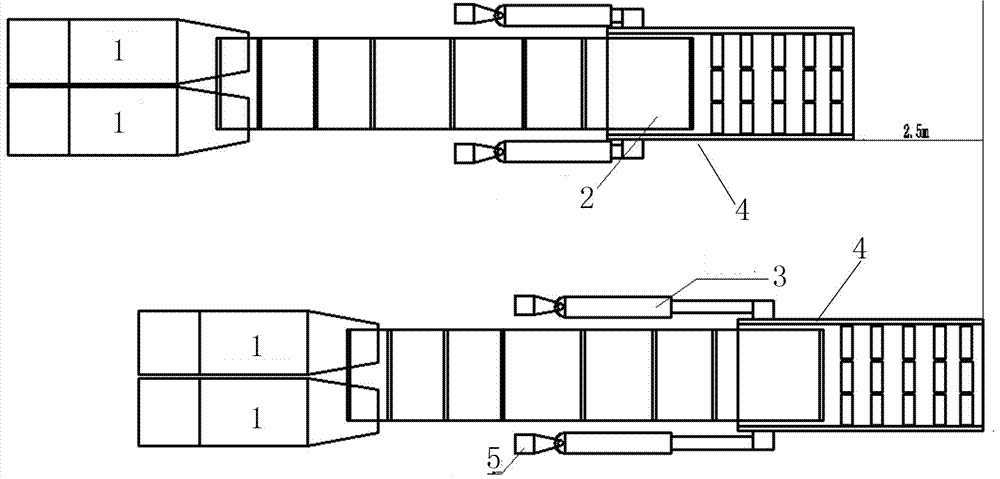

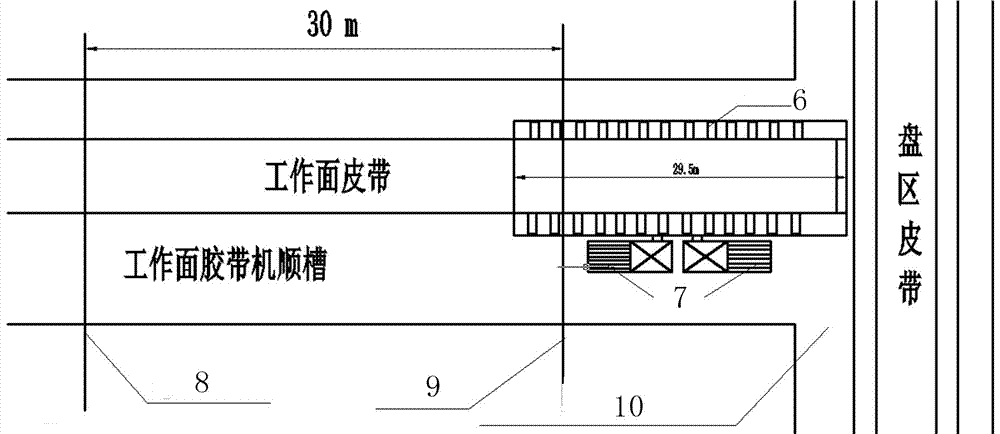

[0028] After careful investigation, research and calculation, it was decided to transfer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com