A roadheader shovel with impact function and its application

A technology for a roadheader and a shovel, which is applied in the field of the shovel of the roadheader, can solve the problems of large propulsion force and large wear on the front end of the shovel, and achieve the effects of increasing the impact function, obvious effect, good economic benefits and market value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

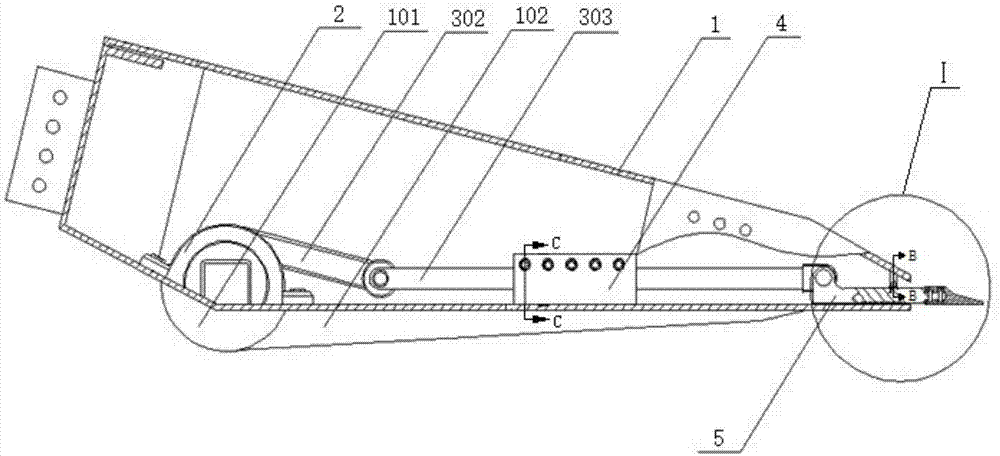

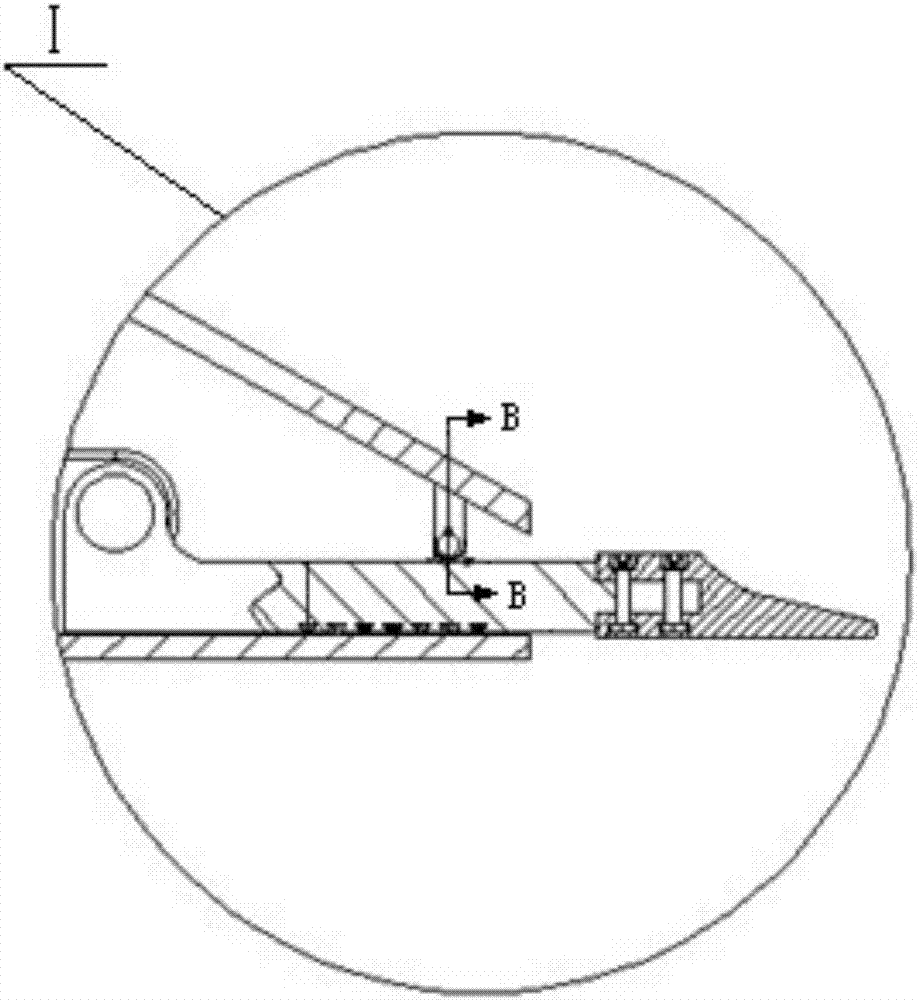

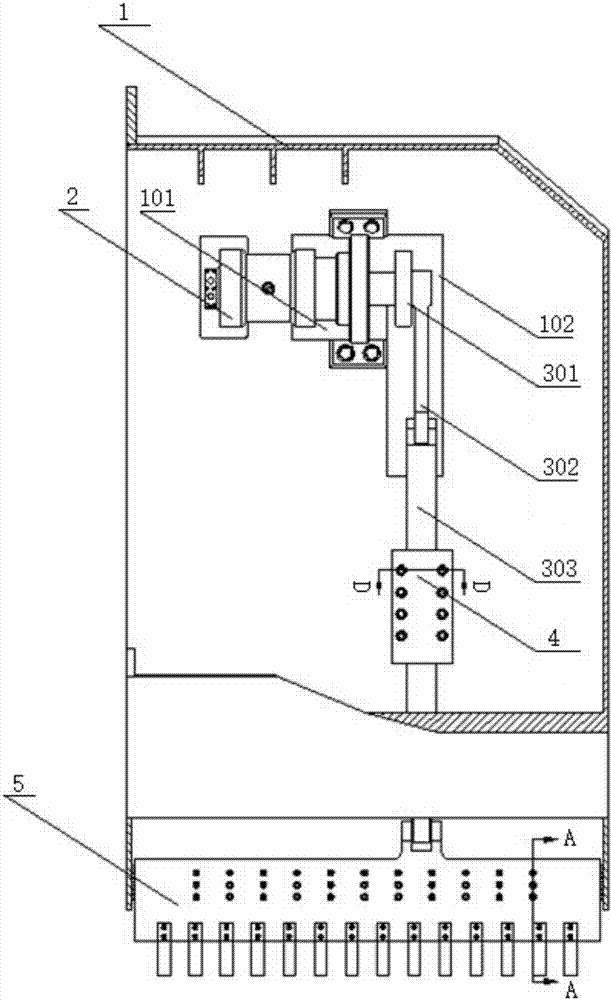

[0036] Such as figure 1 , figure 2 As shown, the present embodiment provides a cutting blade with an impact function, including a blade housing 1 and a blade head 5, a telescopic mechanism is arranged on the blade housing 1, and one end of the telescopic mechanism is connected to the blade head 5 , drive the shovel head 5 to reciprocate through the telescopic mechanism.

[0037] Wherein, the telescoping mechanism includes a power source and a crank link mechanism, the power source is connected in transmission with the crank link mechanism, and one end of the crank link mechanism is connected to the shovel head 5 . In this embodiment, the power source is a hydraulic motor with high torque and low speed. The hydraulic motor is small in size and easy to install.

[0038] The crank-link mechanism includes a crank 301 , a connecting rod 302 and a sliding rod 303 connected in sequence, the hydraulic motor is in transmission connection with the crank 301 , and the connecting rod i...

Embodiment 2

[0043] This embodiment provides a roadheader shovel with an impact function, the structure of which is as described in Embodiment 1, the difference lies in that the power source is a motor. There are 10 rows of cylindrical rollers symmetrically arranged on both sides of the bottom of the shovel head 5, and 15 rows of ball groups are arranged in parallel between the cylindrical rollers on both sides. The adjacent ball groups are arranged at equal intervals, and each row of ball groups contains 5 Ball 6.

Embodiment 3

[0045] Such as Figure 8 and Figure 9 As shown, a roadheader shovel with impact function, the structure is as described in Embodiment 1, the difference is that cylindrical rollers 8 are symmetrically arranged on the left and right sides of the slide rail seat 4, and cylindrical rollers are arranged symmetrically on the upper and lower sides. Roller. The cylindrical rollers on the upper and lower sides are alternately distributed with the cylindrical rollers on the left and right sides. Installing cylindrical rollers 8 up, down, left, and right inside the slide rail seat 4 can make the slide bar move more smoothly, and the rolling friction is easier than the sliding friction.

[0046] One side of the cylindrical roller is provided with a cylindrical roller baffle 7, which can effectively prevent the radial movement of the cylindrical roller 8 and only ensure the axial rotation of the cylindrical roller 8. Bolts are installed at both ends of the cylindrical roller 8 to preve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com