Clean method for separating and refining 3-hydroxypropanesulfonic acid

A technology of hydroxypropanesulfonic acid and sodium hydroxypropanesulfonate, which is applied in the cleaning field of acidification of organic sodium sulfonate, can solve the problems of difficulty in reaching the electronic level of lithium batteries, cumbersome production and operation, equipment corrosion and high cost of manual operation, etc. Achieve the effect of realizing automatic continuous operation, reducing labor operation intensity and saving the consumption cost of hydrochloric acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

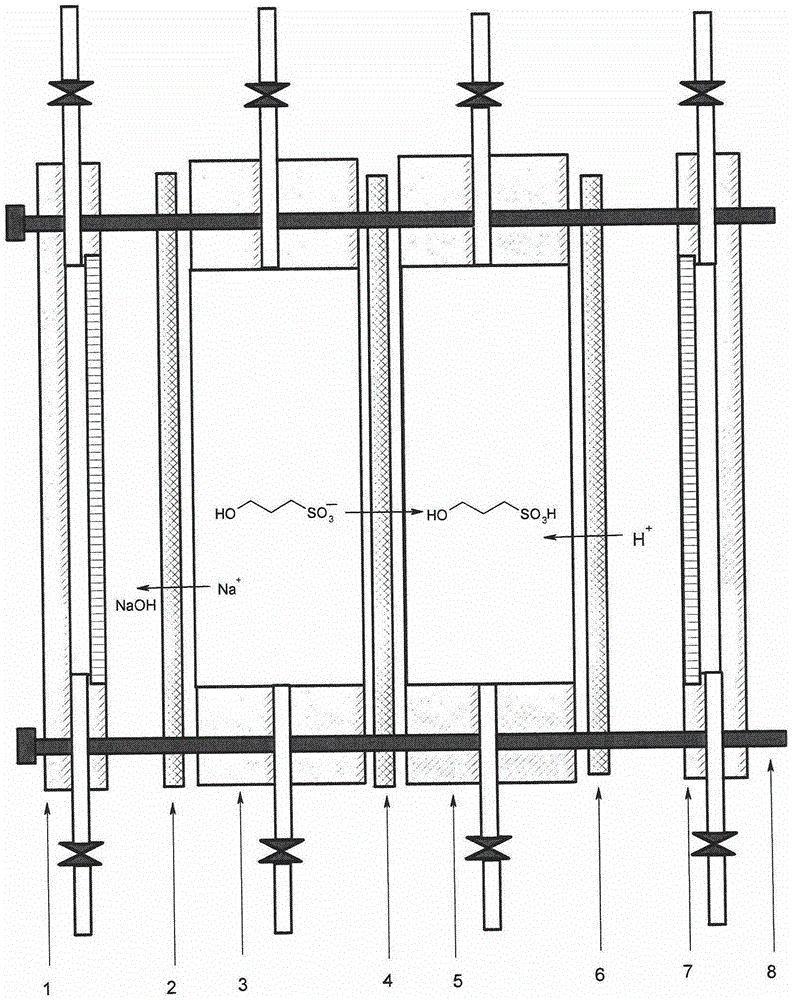

[0040] Add 2500g of 1% dilute sulfuric acid in a 5000ml beaker A, input it into the positive plate layer with circulation pump A, overflow back to beaker A; add 3000g of 32%wt aqueous sodium 3-hydroxypropanesulfonate in 5000ml beaker B, Heat in a water bath to keep the 3-hydroxypropanesulfonate aqueous solution at a constant temperature of 30-40°C, pump it into the third layer with circulation pump B, overflow back to beaker B; add 2000g of pure water to 5000ml beaker C, and start the circulation pump C is sent to the fifth layer plate frame, and overflows back to beaker C; finally, 3000g tap water is added to 5000ml beaker D, pumped into the negative plate layer by circulating pump D, and overflows back to beaker D. After the four circulating pumps are all started to cycle, connect the positive and negative electrodes with 8V DC, and the current quickly rises from 3.8A to 32.6A. The pH value of the material in beaker B is continuously sampled and tested. From the initial pH = ...

Embodiment 2

[0042]Add 2500g of 1% dilute sulfuric acid in a 5000ml beaker A, input it into the positive plate layer with circulation pump A, and overflow back to the beaker A; add 3000g of 36%wt sodium 3-hydroxypropanesulfonate aqueous solution in the 5000ml beaker B, Heat in a water bath to keep the 3-hydroxypropanesulfonate aqueous solution at a constant temperature of 30-40°C, pump it into the third layer with circulation pump B, overflow back to beaker B; add 2000g of pure water to 5000ml beaker C, and start the circulation pump C is sent to the fifth layer plate frame, and overflows back to beaker C; finally, 3000g tap water is added to 5000ml beaker D, pumped into the negative plate layer by circulating pump D, and overflows back to beaker D. After the four circulating pumps are all started to cycle, connect the positive and negative electrodes with 8V DC, and the current quickly rises from 4.3A to 38.8A. The pH value of the material in beaker B is continuously sampled and tested. Fr...

Embodiment 3

[0044] Add 2500g of 1% dilute sulfuric acid in a 5000ml beaker A, input it into the positive plate layer with circulation pump A, overflow back to beaker A; add 3000g of 32%wt aqueous sodium 3-hydroxypropanesulfonate in 5000ml beaker B, Heat in a water bath to keep the 3-hydroxypropanesulfonate aqueous solution at a constant temperature of 30-40°C, pump it into the third layer with circulation pump B, overflow back to beaker B; add 2000g of pure water to 5000ml beaker C, and start the circulation pump C is sent to the fifth layer plate frame, and overflows back to beaker C; finally, 3000g tap water is added to 5000ml beaker D, pumped into the negative plate layer by circulating pump D, and overflows back to beaker D. After the four circulating pumps are all started to cycle, connect the positive and negative electrodes with 9V direct current, and the current rapidly rises from 4.7A to 46.3A. The pH value of the material in beaker B is continuously sampled and tested. From the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com