Special grease for worm and gear and preparation method thereof

A worm gear and lubricating grease technology, applied in lubricating compositions, petroleum industry, etc., can solve the problems of rising use cost, short oil service life, corruption, etc., achieve good extreme pressure and anti-wear properties, reduce gear wear, and prolong service life The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

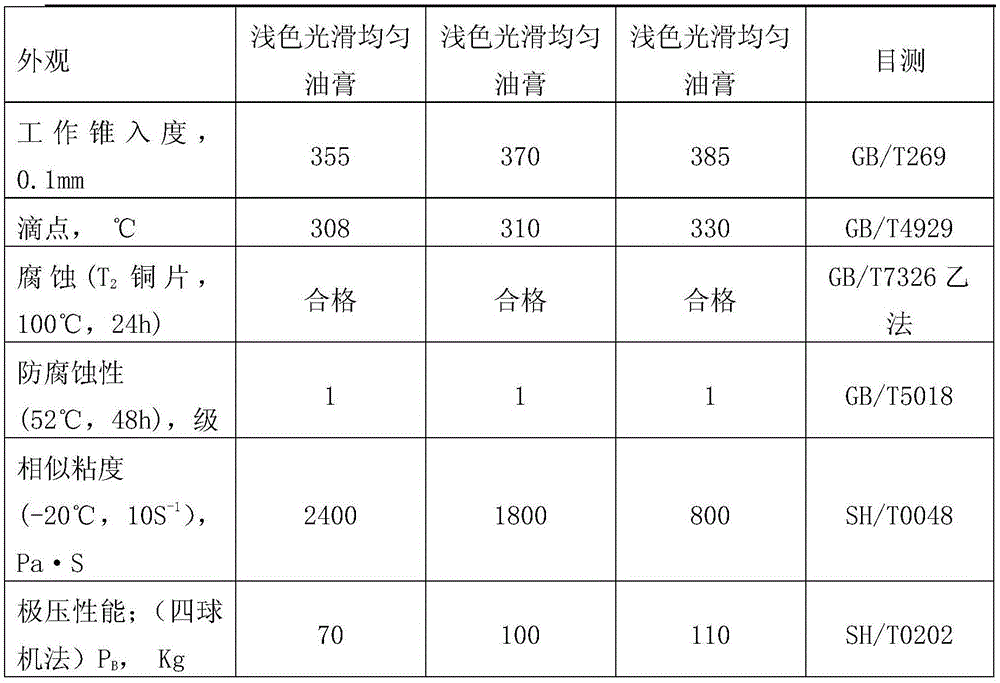

Examples

preparation example Construction

[0032] The preparation method of this special lubricating grease for worm gears adopts a high-speed convection contactor, and under the condition of not exceeding 80°C, 80% of the total amount of oil is added according to the specified weight ratio. B, isocyanate, heat up to 100°C-115°C for saponification reaction, saponification for 1-2 hours; heat up to 190-200°C for refining, keep warm for 60-90 minutes; transfer to an intermediate kettle, add 20% of the total amount of oil Thickening of high-grade refined mineral oil; cooling, temperature to 140---160 ° C, dispersing and cyclic shearing; cooling to 100-130 ° C and homogenizing once; cooling to 80-100 ° C, adding inorganic soil, tackifier A, anti Oxygen agent, extreme pressure anti-wear agent, stir evenly; after passing the test, degas, filter, and pack.

[0033] The purpose of the present invention is achieved through the following technical solutions. This kind of special grease for worm gear is refined ore with high vis...

example 1

[0035] Special lubricating grease for worm gears and worms, characterized in that it uses high-viscosity refined mineral oil as base oil, uses organic and inorganic mixed soap as thickener, adds extreme pressure anti-wear agent, antioxidant, and thickener, and the weight of each component The ratio is as follows:

[0036] High viscosity refined mineral oil: 55

[0037] Octadecylamine: 2

[0038] Aniline: 1

[0039] Dialkyl diphenylamine: 0.7

[0040] Isocyanate: 2.5

[0041] Inorganic Soil: 6

[0042] Sulfurized isobutylene: 2

[0043] Ethylene Propylene Copolymer: 3

[0044] Polyisobutylene: 36.

[0045] The production process of lubricating grease for worm gear is as follows:

[0046] Using a high-speed convection contactor, at 60°C, add high-viscosity refined mineral oil (80% of the total amount of oil added), octadecylamine, aniline, ethylene-propylene copolymer, and isocyanate according to the specified weight ratio, and heat up to 100°C- Saponification reaction ...

example 2

[0048] Special lubricating grease for worm gears and worms is characterized by using high-viscosity refined mineral oil as base oil, organic and inorganic soaps as thickeners, adding extreme pressure anti-wear agents, antioxidants, and thickeners, and the weight of each component For example:

[0049] Naphthyl refined mineral oil: 65

[0050] Octadecylamine: 1.8

[0051] Aniline: 1.2

[0052] Di-tert-butyl-p-cresol: 0.7

[0053] Isocyanate: 2.5

[0054] Tricresyl Phosphate: 1

[0055] Inorganic soil: 7.5

[0056] Sulfurized isobutylene: 1

[0057] Ethylene Propylene Copolymer: 5

[0058] Polyisobutylene: 24.

[0059] The production process of special lubricating grease for worm gear is as follows:

[0060] Using a high-speed convection contactor, at 60°C, add high-viscosity refined mineral oil (70% of the total amount of oil added), octadecylamine, aniline, ethylene-propylene copolymer, and isocyanate according to the specified weight ratio, and heat up to 100°C- Carry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com