Environment-friendly wood floor

A wood floor, environmentally friendly technology, used in coatings, layered products, construction, etc., can solve problems such as easy dizziness, unpleasant smell, etc., achieve excellent waterproof performance, and inhibit the release of formaldehyde.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

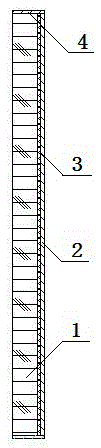

[0014] This environment-friendly wooden floor includes a board body 1, a layer of paint layer 2 is coated on the board body 1 surface, and a layer of waterproof layer 3 is coated on the surface of the paint layer, and a layer of colored wax layer 4 is coated on the outer side of the board body, and the waterproof layer It is made of the following raw materials in parts by weight: 2 parts of nickel slag, 15 parts of pigskin, 6 parts of pine tar, 5 parts of pigment, 60 parts of amino resin, and 6 parts of sodium carboxymethyl cellulose;

[0015] The production method is as follows: at 180°C, mix nickel slag, pigskin, pine charcoal, pigment, amino resin, and sodium carboxymethyl cellulose, and stir for 6 hours.

Embodiment 2

[0017] The structure of this embodiment is the same as that of Embodiment 1, and the waterproof layer is made of the raw materials of the following parts by weight:

[0018] 10 parts of nickel slag, 10 parts of pigskin, 2 parts of pine tar, 10 parts of pigment, 70 parts of amino resin, 2 parts of sodium carboxymethyl cellulose;

[0019] The production method is as follows: at 180°C, mix nickel slag, pigskin, pine charcoal, pigment, amino resin, and sodium carboxymethyl cellulose, and stir for 6.5 hours.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap