Projection screen coating paint, preparation method and coating forming method

A technology of projection screen and molding method, which is applied in the direction of coating, polyurea/polyurethane coating, and the device for coating liquid on the surface, etc., which can solve the problems of difficult transportation and installation, limited screen size, etc., and achieve high contrast and convenient operation , the effect of good optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

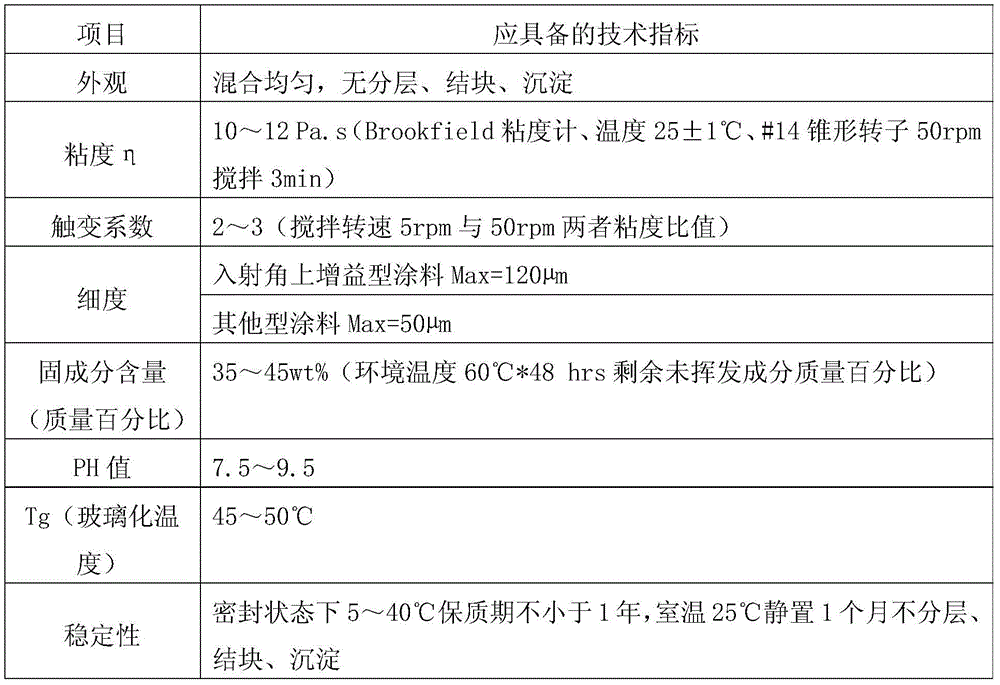

[0045] Projection screen coating paint, the mass percentages of the components of the paint are: 65%-75% of self-crosslinking water-soluble resin, 3%-5% of solvent, 8%-10% of film-forming aid, disinfectant Foaming agent 0.3%~0.5%, leveling agent 0.3%~0.5%, thickener 0.3%~0.5%, matting agent 0.1%~0.3%, preservative 0.1%~0.3%, filler 5%~8%, coloring Agent 1% to 3%.

[0046] For the above-mentioned components, generally select them in the following ways: 1. Self-crosslinking water-soluble resin: coating film-forming base material, acrylic acid, methyl methacrylate, styrene, acrylic acid-β -Hydroxylactone, triethylamine, ethylenediamine, ammonium persulfate, distilled water, etc. are processed through a series of processes, and added in a certain order, mixed in a nitrogen atmosphere, heated, stirred, cooled, filtered, etc., and then a self-crosslinking emulsion Acrylic-polyurethane water-based dispersion, or purchased finished water-soluble self-crosslinking type acrylic resin a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com