High-slippery-resistance tire tread rubber composite material and preparation method thereof

A technology for tire treads and composite materials, which is applied in the rubber field to reduce rolling resistance and improve wet skid resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] A kind of preparation method of high anti-wet skid tire tread rubber composite material provided by the invention comprises the following steps:

[0049] Each component is weighed according to the above parts by weight, and the following mixing method is adopted for refining:

[0050] One-stage mixing: In the internal mixer, the filling factor is 0.66-0.72, adding solution polystyrene butadiene rubber, butadiene rubber, rare earth 3,4-isoamyl rubber, white carbon black, carbon black and silane coupling agent for mixing Mixing, the temperature of the rubber material is controlled at 145°C-165°C during mixing, and the mixing time is 180-240 seconds. After the mixing is completed, the rubber material is removed to obtain a section of mixed rubber;

[0051] Two-stage mixing: Put the first-stage compound rubber, zinc oxide, stearic acid, anti-aging agent, and plasticizer into the internal mixer for mixing. The mixing temperature is controlled at 130-150°C, and the mixing tim...

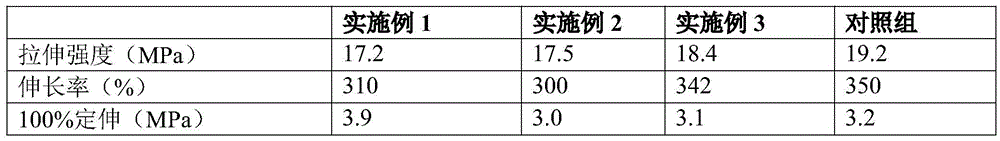

Embodiment 1

[0055] Embodiment 1: The formulation of the rubber compound is shown in Table 1.

[0056] One-stage mixing: In the internal mixer, the filling factor is 0.7±0.02, add all the raw rubber (solution polystyrene butadiene rubber, butadiene rubber and 3,4-isoamyl rubber), white carbon black and carbon black, silane The coupling agent is mixed. During mixing, the temperature of the rubber material is controlled at 150°C±5°C, and the mixing time is 240 seconds. After the mixing is completed, the rubber material is unloaded to obtain a section of mixed rubber.

[0057] Two-stage mixing: Put the first-stage compound rubber, zinc oxide, stearic acid, anti-aging agent, and plasticizer into the internal mixer for mixing. The mixing temperature is controlled at 145±5°C, and the mixing time is 180 seconds. After the mixing is completed, the rubber material is unloaded to obtain a second-stage mixed rubber.

[0058] Three-stage mixing: add the second-stage compound rubber, sulfur and acce...

Embodiment 2

[0059] Embodiment 2: The formulation of the rubber compound is shown in Table 1.

[0060] One-stage mixing: In the internal mixer, the filling factor is 0.7±0.02, add all the raw rubber (solution polystyrene butadiene rubber, butadiene rubber and 3,4-isoamyl rubber), white carbon black and carbon black, silane The coupling agent is mixed. During mixing, the temperature of the rubber material is controlled at 160°C±5°C, and the mixing time is 180 seconds. After the mixing is completed, the rubber material is unloaded to obtain a section of mixed rubber.

[0061] Two-stage mixing: Put the first-stage compound rubber, zinc oxide, stearic acid, anti-aging agent, and plasticizer into the internal mixer for mixing. The mixing temperature is controlled at 135±5°C, and the mixing time is 240 seconds. After the mixing is completed, the rubber material is unloaded to obtain a second-stage mixed rubber.

[0062] Three-stage mixing: add the second-stage compound rubber, sulfur and acce...

PUM

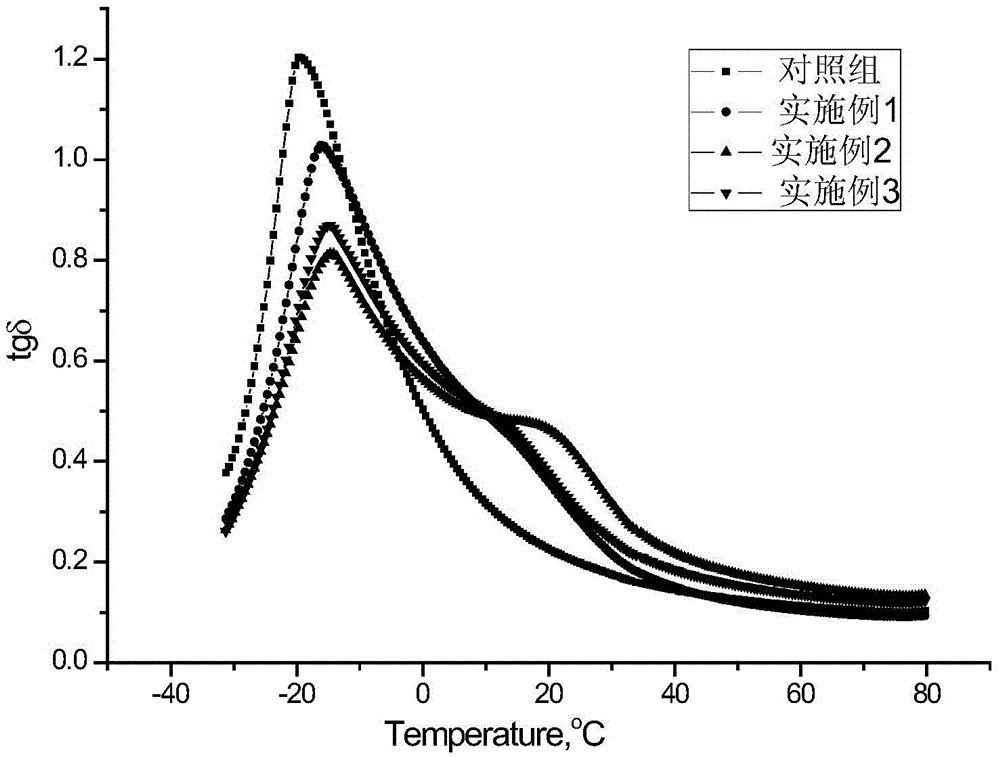

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com