Sludge treatment efficiency improvement system and method

A sludge treatment and treatment system technology, which is applied in the directions of sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problems of large resource consumption and low treatment efficiency, and achieve reduction Activation energy, saving energy consumption, effect of temperature drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

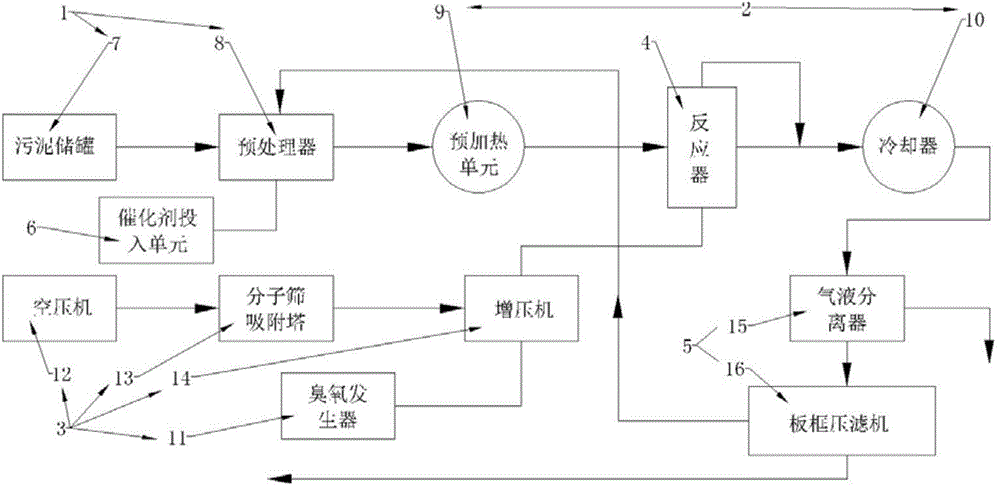

[0038] The present invention proposes a system for improving sludge treatment efficiency. The treatment system includes a pretreatment unit 1, a heat exchange unit 2, an oxidation matrix unit 3, a reactor 4, a separation unit 5, and a catalyst input unit 6. The reactor 4 are respectively connected to the heat exchange unit 2, the oxidation matrix unit 3 and the separation unit 5, and the pretreatment unit 1 is respectively connected to the heat exchange unit 2, the separation unit 5 and the catalyst input unit 6.

[0039] The pretreatment unit 1 includes a sludge storage tank 7 for storing sludge, a preprocessor 8 connected to the sludge storage tank 7 and a catalyst input unit 6, a solid pump for transporting sludge, and a Stirrer in Processor 8.

[0040]In the pretreatment unit 1, the sludge with a water content of 75% to 85% in the sludge storage tank 7 is injected into the preprocessor 8 with a solid pump, and the liquid phase of the separation unit 5 is returned to the pr...

Embodiment 2

[0059] The present invention also provides a method for improving sludge treatment efficiency, said treatment method comprising the steps of:

[0060] A. Inject the sludge stored in the sludge storage tank 7 into the preprocessor 8 with a solid pump, mix it with the liquid phase reflux water of the separation unit 5 in the preprocessor 8, and add the catalyst through the catalyst input unit 6, and prepare into a material with a moisture content of 90%.

[0061] In the sludge storage tank 7, the sludge with a water content of 75% to 85% is mixed with the liquid-phase backflow water to form a material with a water content of 90%. The liquid-phase circulating water is acidic with a pH of 4 to 5. Under the action of acid, the sludge will break down, causing some cells to dissolve and free water to increase. Moreover, due to the high temperature of the return water, the original sludge will be preheated. . Under the synergy of these aspects, the fluidity of the mixed sludge in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com