Automatic fed-batch type efficient iron salt denitrification reaction device and automatic fed-batch type efficient iron salt denitrification reaction method for bacteria

A technology of iron salt denitrification and reaction device, applied in chemical instruments and methods, water pollutants, water/sludge/sewage treatment, etc., can solve the problems of hindering the communication between cells and external substances, low removal rate, death, etc. Achieve the effect of maintaining high efficiency and stability, ingenious design, and clear partitions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in combination with specific drawings and specific embodiments. Unless otherwise stated or conflicted, the various preferred implementation modes can be combined arbitrarily.

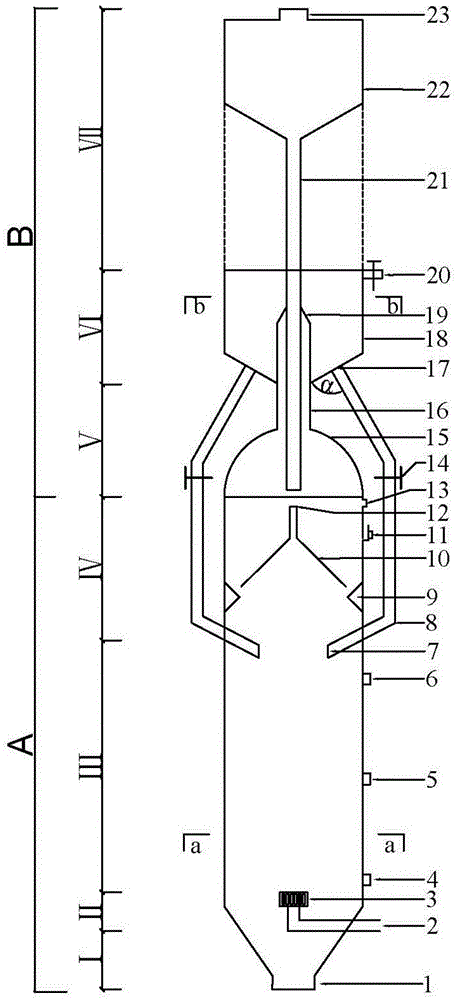

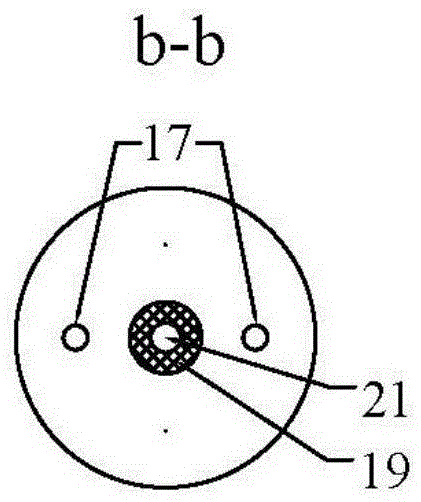

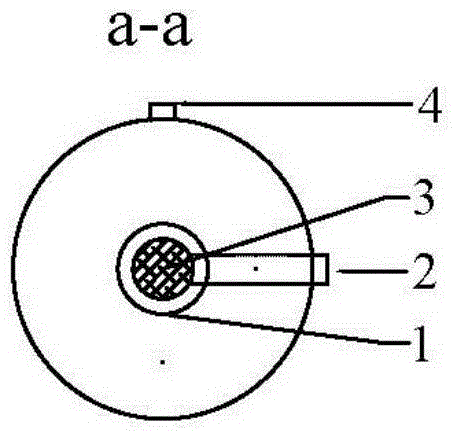

[0026] like figure 1 , 2 , 3, and 4 show a self-flowing type high-efficiency iron salt denitrification reaction device. The whole device is divided into two parts: reaction tank A and seed tank B; reaction tank A includes sludge discharge area I, water distribution area II, reaction area III and three-phase separation area IV; seed tank B includes liquid storage area V and breeding area VI And energy storage area VII, the device specifically includes the first mud discharge port 1, water inlet 2, water distributor 3, lower sampling port 4, middle sampling port 5, upper sampling port 6, mud feeding port 7, flow feeding pipe 8. Side separation baffle 9, separation baffle 10, water outlet 11, separation exhaust port 12, first exhaust port 13, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com