Semi-overlapped bagging type gas drilling and sealing device

A gas drilling and sealing device technology, which is applied in the direction of gas discharge, safety devices, earthwork drilling, etc., can solve the problems of difficulty in increasing the concentration of gas drainage, sealing the drainage pipe, plugging the plugging section, etc., to achieve The effects of labor intensity reduction, pollution reduction and cost reduction

Pending Publication Date: 2022-06-28

辽宁兰特科技发展有限公司

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

③ Both ends of the plugging section are open ends, and the injection type plugging is adopted, and the problem of "plugging" in the deep part of the plugging section needs to be solved, otherwise it will cause material to run out, and even the air inlet of the exhaust pipe will be blocked, resulting in Scrap hole

Under the calibrated negative pressure of 13 kPa, the air permeability causes gas circulation and channeling inside and outside the borehole, making it difficult to increase the concentration of gas drainage

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0016] No complex process operations are required on site. Manually (or with a simple tool) open the middle isolation of the inner bag, mix the two-component materials in the bag, remove the protective film of the waterproof glue, take the pipe and enter the hole at the same time.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

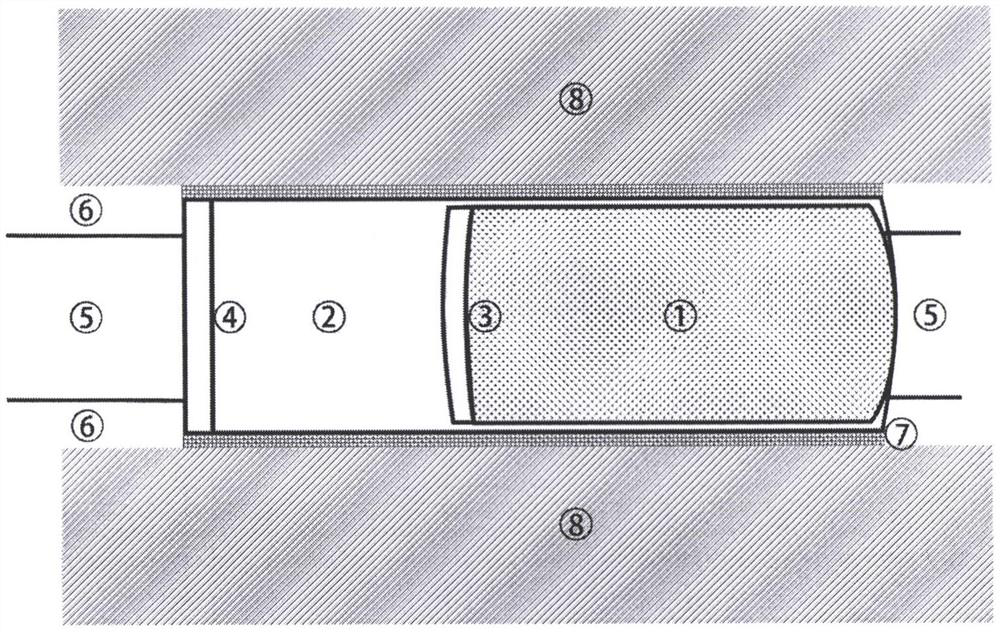

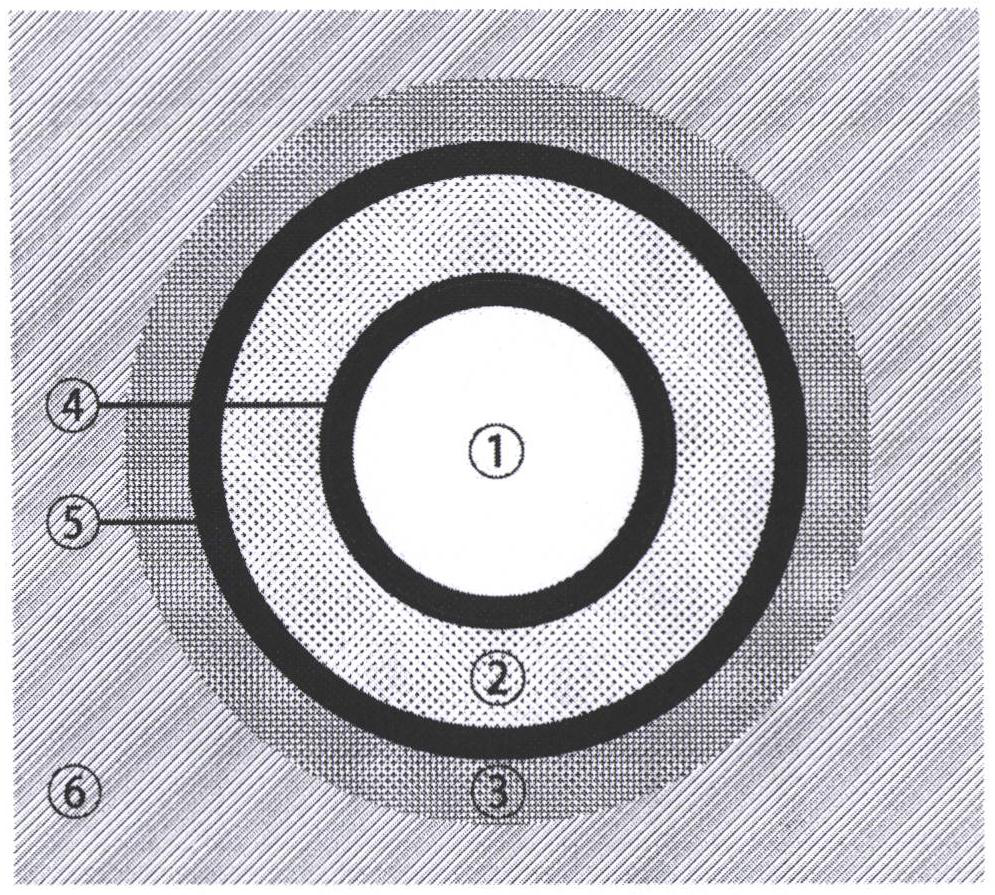

Login to View More Abstract

The invention discloses a semi-overlapped bagging type gas drilling and sealing device, and aims to improve the gas extraction concentration, prevent the occurrence of underground coal mine gas accidents and improve the utilization efficiency of gas serving as clean energy. The gas drainage hole sealing body ventilation problem and the circular seam ventilation problem occurring between the sealing body and the drill hole wall and between the sealing body and the drainage pipe are solved. According to the technical scheme for solving the problem, two kinds of materials of a pouring type polyurethane expansion body contained in a flexible bag serve as power sources, a semi-overlapped sleeve bag formed by combining an inner bag and an outer bag serves as a main line, and a corresponding mechanism is arranged on the main line so as to control the expansion pressure of the sleeve bag and conduct the expansion pressure in a closed-loop mode.

Description

technical field [0001] When it comes to gas, people often think of gas accidents, especially vicious gas accidents. The harm to life and property is unacceptable to the whole society. On the other hand, gas, also known as coalbed methane, is a clean energy source. The invention relates to a semi-overlapping bagging type gas drilling and sealing device, which can prevent the occurrence of gas accidents, improve the gas collection capacity and utilization rate, and reduce the harm to the environment. Background technique [0002] Drilling, sealing and draining, in coal mines, especially in high gas mines, have always been the basic means and normalized work flow to prevent gas accidents. In these three links, sealing is the key. Blocking gas drainage holes is different from blocking ordinary holes and holes, and it is also a highly technical process. The level of sealing quality is directly related to the concentration of gas drainage. It is necessary to briefly describe t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E21B33/13E21F7/00

CPCE21B33/13E21F7/00

Inventor 国帆杜一宁刘刚苏伟郭昕

Owner 辽宁兰特科技发展有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com