Aging method for preparing pseudo-boehmite by carbonation method

A technology of pseudo-boehmite and carbonation, which is applied in chemical instruments and methods, preparation of alumina/aluminum hydroxide, alkali metal aluminate/aluminum oxide/aluminum hydroxide, etc., and can solve miscellaneous items and temperature raising of slurry Long process, high energy consumption of the aging process, etc., to achieve the effect of high crystallinity, lower production cost, and less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

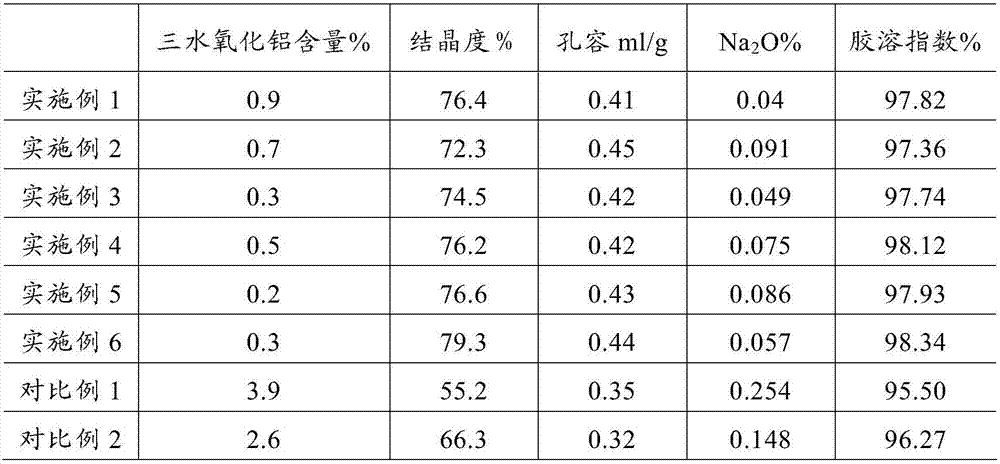

[0014] A carbonation method for preparing pseudo-boehmite aging method provided in Example 1 of the present invention is specifically as follows: using sodium aluminate refined solution produced by soda lime sintering method as raw material, adjusting its alumina content to 42g / l, The caustic ratio is 1.52, and industrial carbon dioxide gas with a volume concentration of 30-40% is introduced. After 15 minutes, the pH value of the slurry is 13, and the obtained slurry is rapidly separated from liquid to solid. Put the separated filter cake into a sealed plastic bag, put it in water at 70°C for 2 hours, add hot water at 80°C to melt the slurry, stir repeatedly, wash and remove impurities, and finally dry it in an oven to obtain a qualified product. Please refer to Attached Table 1 for product indicators.

Embodiment 2

[0016] A carbonation method for preparing pseudo-boehmite aging method provided in Example 2 of the present invention is specifically as follows: using sodium aluminate refined solution produced by soda lime sintering method as raw material, adjust its alumina content to 23g / l, The caustic ratio is 1.37, and industrial carbon dioxide gas with a volume concentration of 30-40% is introduced. After 10.5 minutes, the pH value of the slurry is 10.5, and the obtained slurry is rapidly separated from liquid to solid. Put the separated filter cake into a sealed plastic bag, put it in water at 90°C for 4 hours, add hot water at 75°C to melt the slurry, stir repeatedly, wash and remove impurities, and dry in an oven to obtain a qualified product. Please refer to Attached Table 1 for product indicators.

Embodiment 3

[0018] A carbonation method for preparing pseudo-boehmite aging method provided in Example 3 of the present invention is specifically as follows: using sodium aluminate refined solution produced by soda lime sintering method as raw material, adjusting its alumina content to 36g / l, The caustic ratio is 1.42, and industrial carbon dioxide gas with a volume concentration of 30-40% is introduced. After 13 minutes, the pH value of the slurry is 11, and the obtained slurry is rapidly separated from liquid to solid. Put the separated filter cake into a sealed flask, put it in water at 95°C and keep it warm for 3.5 hours, then add hot water at 95°C to melt the slurry, perform repeated stirring, washing and impurity removal, and dry in an oven to obtain a qualified product. Please refer to Attached Table 1 for product indicators.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com