Automatic molding equipment and method for producing hard carbon / graphite felt tube material

A technology for forming equipment and graphite felt, which is applied in the field of carbon/graphite felt preparation, can solve the problems of adverse effects on thermal insulation performance, long production and operation time, and poor adhesion, so as to reduce labor and material costs, improve service life, Not easy to layer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

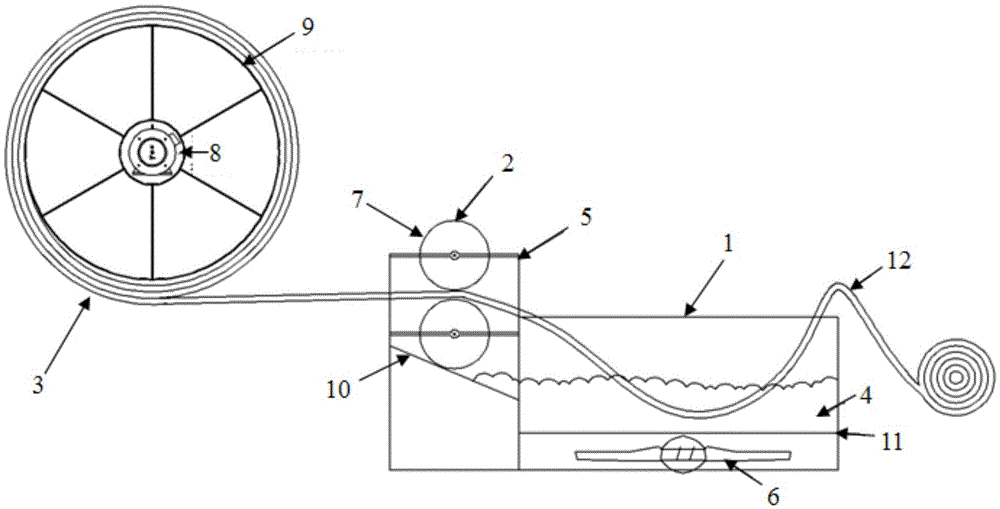

[0031] as attached figure 1 The shown automatic molding equipment for making hard carbon / graphite felt cylinders includes an impregnation device 1 connected to an extrusion device 2 , and the extrusion device 2 is connected to a winding device 3 .

[0032] The dipping device 1 includes a dipping tank 5 filled with an adhesive 4 , the bottom of the dipping tank 5 is provided with a stirring device 6 , the bottom of the dipping device 1 is connected to a wire filter 11 , and the wire filter 11 is located above the stirring device 6 . The purpose of stirring device 6 is to ensure that the graphite powder in the binder 4 does not precipitate during the process of immersing the soft carbon felt 12 into the binder 4 in the dipping tank 5, so that the sticky substance immersed in the soft carbon felt 12 The graphite powder of the mixture 4 has a stable composition ratio, so that the adhesive properties of the adhesive 4 can be fully exerted.

[0033] The extrusion device 2 includes ...

Embodiment 2

[0036] Utilize the automatic forming equipment described in embodiment 1 to make the working process of hard carbon / graphite felt cylinder material be:

[0037] The first step: Wrap a layer of sulfuric acid paper on the inner mold 9 of the cylinder, attach graphite paper, and then use an adhesive to attach a layer of carbon cloth to the surface of the graphite paper;

[0038] Step 2: Turn on the automatic forming equipment for the hard carbon / graphite felt tube material, select the target tube material diameter as 380 mm, and adjust the rotation speed of the motor 8 to 3 min / turn.

[0039] The third step: first dip the soft carbon felt 12 into the adhesive 4 in the dipping tank 5, and then extrude the excess adhesive 4 through the reverse rotation extrusion process of the upper and lower wheels of the extrusion wheel 7, Flow back into the dipping tank 5 through the deflector 10, and the extruded soft carbon felt 12 is evenly and tightly wound on the inner membrane 9 of the tub...

Embodiment 3

[0051] The basic process of the present embodiment and embodiment 2 is identical, and different parameters and steps are as follows:

[0052] 1. Step 2: Turn on the automatic forming equipment for the hard carbon / graphite felt tube material, select the target tube material diameter as 600mm, and adjust the rotation speed of the motor 8 to 5 min / turn.

[0053] 2. The fifth step: after the high-temperature carbonization heat treatment shown in Table 8, the hard graphite felt tube material is obtained.

[0054] Table 8 High temperature carbonization heat treatment process conditions b

[0055]

[0056]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com