A kind of ferrite sheet and preparation method thereof

A ferrite sheet and ferrite technology, applied in the field of ferrite sheet and its preparation, can solve the problems of low efficiency, cumbersome process, and inability to fully reflect the performance of ferrite materials, and achieve the effect of improving the reading and writing distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

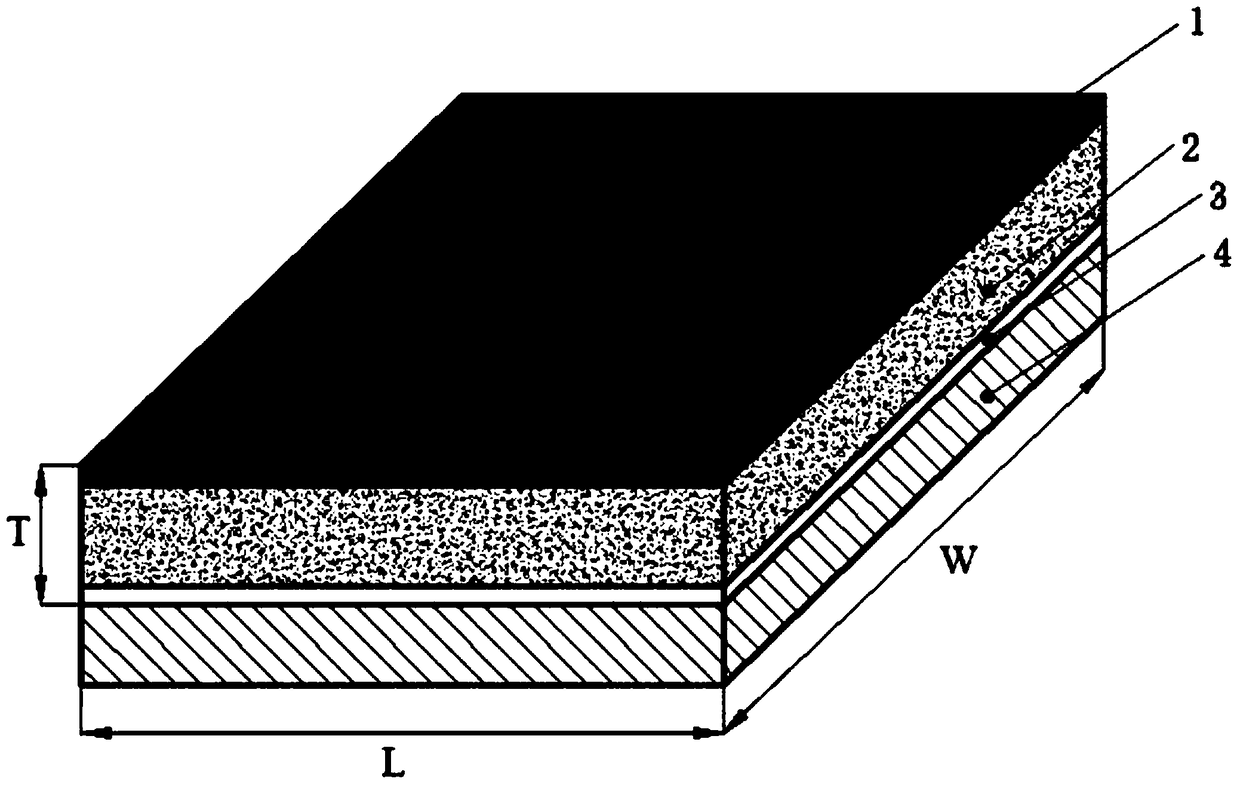

Image

Examples

Embodiment 1

[0037] A ferrite sheet comprising 100 parts by weight of NiCuZn ferrite powder:

[0038] 2 parts of binder; 1 part of plasticizer; 20 parts of solvent.

[0039] The average particle size of the NiCuZn ferrite powder in this embodiment is 0.60 μm.

[0040] In this embodiment, the binder is polyvinyl butyral.

[0041] In this embodiment, the plasticizer is dimethyl phthalate.

[0042] In this embodiment, the solvent is acetone.

[0043] The preparation method of above-mentioned ferrite sheet, comprises the following steps:

[0044] 1) Mix 100 parts of NiCuZn ferrite powder and 20 parts of solvent by ball milling for 1 hour;

[0045] 2) Add 2 parts of binder, ball mill and mix for 6 hours;

[0046] 3) Add 1 part of plasticizer, ball mill and mix for 1 hour;

[0047] 4) Take the uniformly mixed slurry in step 3), put it on a tape casting machine to prepare a green sheet;

[0048] 5) Pressing the green sheet, the thickness of the green sheet is 8%, and the stretch of the gre...

Embodiment 7

[0056] A ferrite sheet comprises 10 parts of binder based on 100 parts by weight of NiCuZn ferrite powder; 5 parts of plasticizer; and 100 parts of solvent.

[0057] The average particle size of the NiCuZn ferrite powder in this embodiment is 1.2um.

[0058] The binder in this embodiment is polyacrylate.

[0059] The plasticizer in this embodiment is polyethylene glycol.

[0060] The plasticizer solvent is ethanol.

[0061] The preparation method of above-mentioned ferrite sheet, comprises the following steps:

[0062] 1) 100 parts of NiCuZn ferrite powder and 100 parts of solvent, mixed by ball milling for 6 hours;

[0063] 2) Add 10 parts of binder, ball mill and mix for 15 hours;

[0064] 3) Add 5 parts of plasticizer, ball mill and mix for 10 hours;

[0065] 4) Take the uniformly mixed slurry in step 3), put it on a tape casting machine to prepare a green sheet;

[0066] 5) Pressing the green sheet, the thickness of the green sheet is compressed by 20%, and the stret...

Embodiment 2~6、8~10 and comparative Embodiment 1~7

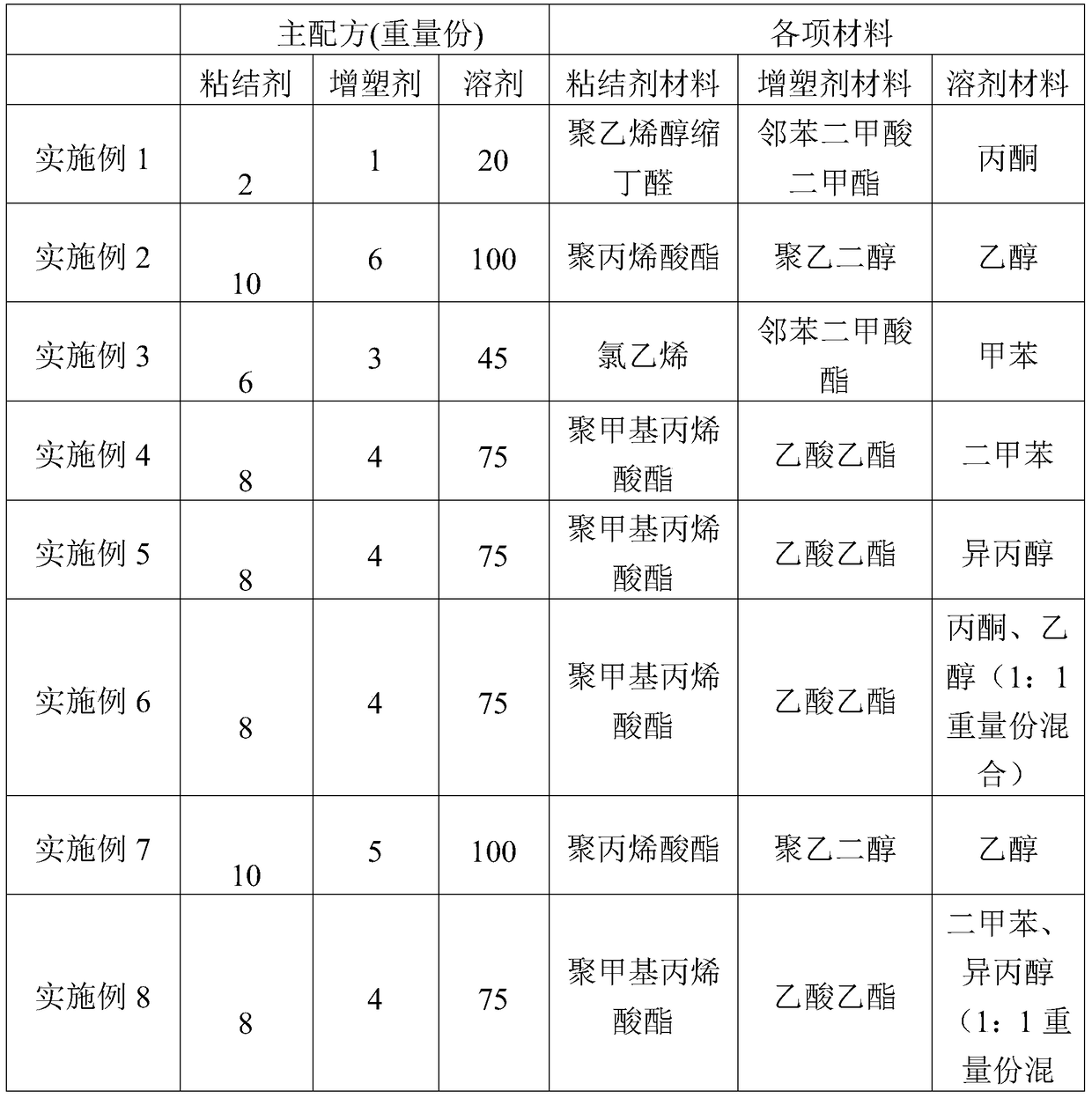

[0072] Embodiments 2~6,8~10 differ from Embodiment 1 or 7 in that:

[0073] Formula composition in the embodiment 1~10 of table 1

[0074]

[0075]

[0076] The preparation technology of table 2 embodiment 1-6 and comparative example 1-4

[0077]

[0078] The preparation technology of table 3 embodiment 7-10 and comparative example 5-7

[0079]

[0080]

[0081] Table 4 Comparison of sintering process, magnetic properties, sheet density and appearance of magnetic sheets

[0082]

[0083]

[0084] Can draw by above-mentioned embodiment and comparative example: by 100 parts by weight of NiCuZn ferrite powder, when binder part is less than 2 parts by weight, the green sheet that casts out becomes brittle, breaks easily; When the amount of the plasticizer is more than 8 parts by weight, the green sheet will have more pores after sintering, resulting in a decrease in the performance of the ferrite sheet; when the plasticizer is less than 1 part by weight, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com