A kind of magnet dismantling tooling used for the production of quartz crystal resonators

A quartz crystal and disassembly tooling technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of high labor cost and low work efficiency, and achieve the effect of reducing labor cost, simple structure and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

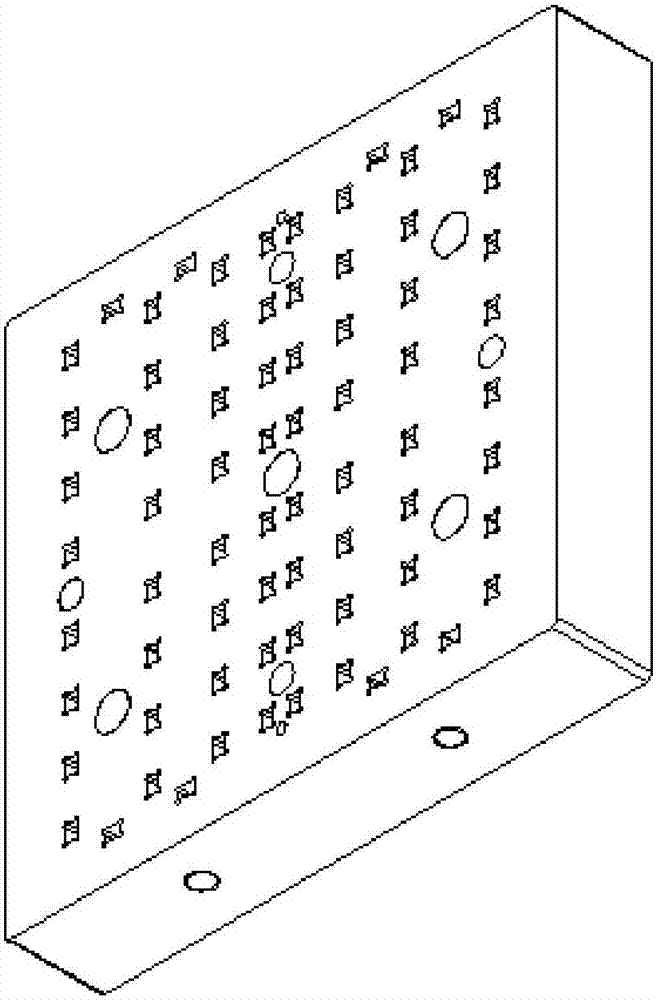

Image

Examples

Embodiment

[0038] First start the cylinder 3, the piston rod protruding from the cylinder 3 drives the top plate 4 to move upward, the positioning rod 7 and the ejector rod 9 pass through the magnet adsorption plate 6 vertically and rise to a certain height, and the hole position of the fixture is aligned with the two positioning rods 7 The limit column 16 at the upper end is aligned, and the lower end surface of the jig is fitted with the upper end surface of the cylinder 17 of the ejector rod 9 and the upper end surface of the cylinder 17 of the positioning rod 7, and the cylinder 3 is started again, and the piston rod protruding from the cylinder 3 drives the top plate 4. Move downward until the lower end surface of the jig fits with the upper end surface of the magnet adsorption plate 6, the magnet 8 in the magnet adsorption plate 6 rises and attracts the magnet in the jig, and then starts the cylinder 3 to connect the jig to the jig. The magnet in the tool is separated, and the reset...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com