A kind of lamp welding device and process

A technology of welding device and welding process, which is applied in the field of welding device and process of automobile lights, and can solve the problems of poor welding uniformity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be noted that, in the case of no conflict, the following technical solutions and technical features can be combined with each other.

[0028] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

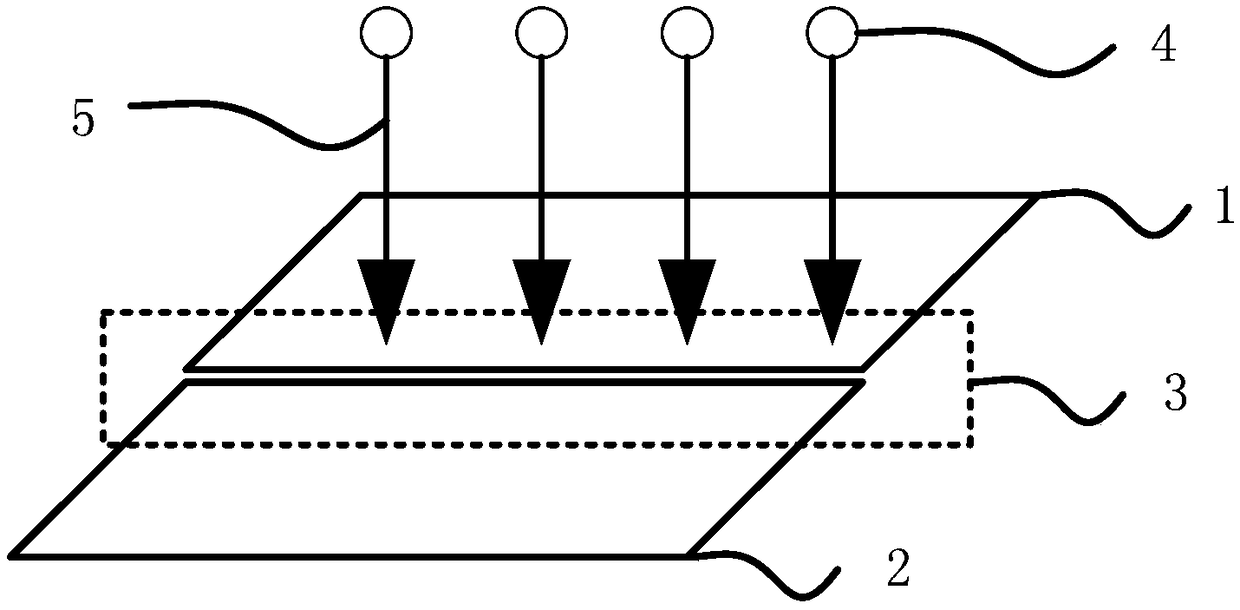

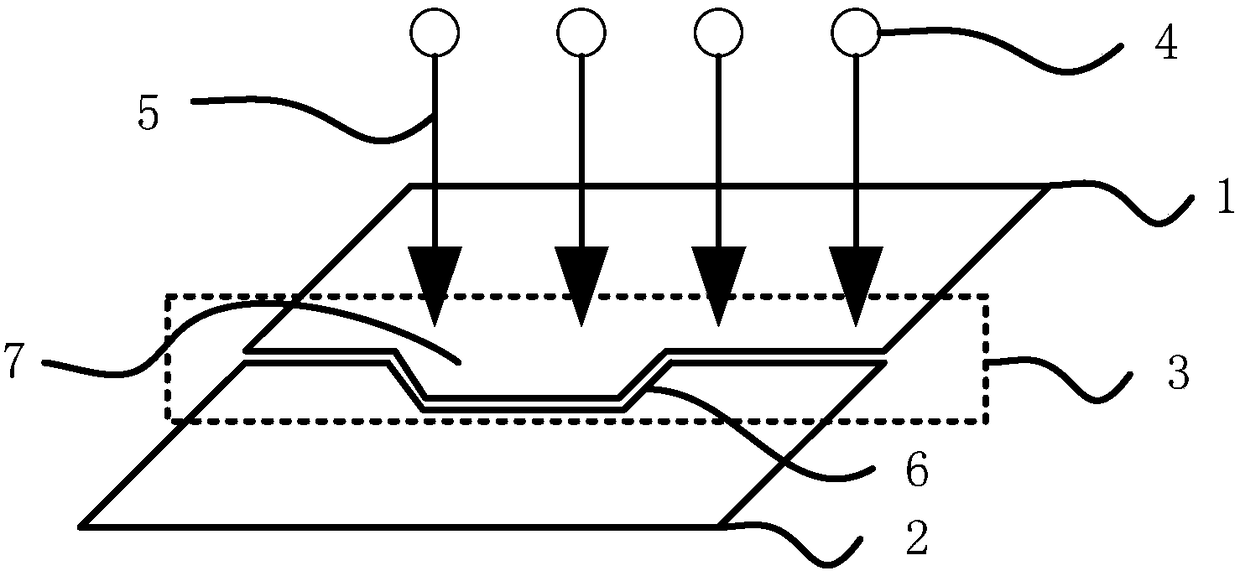

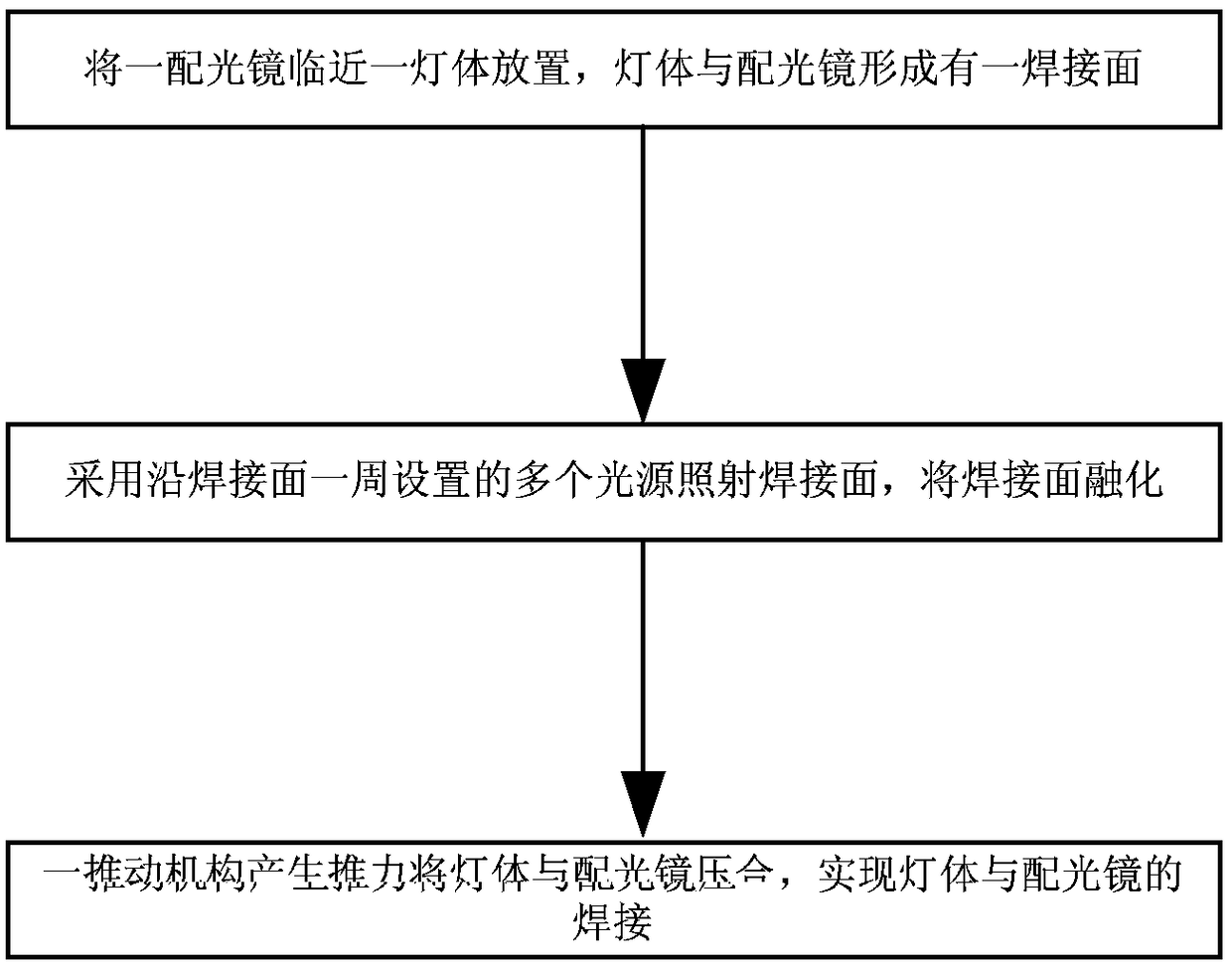

[0029] A car lamp welding device, such as figure 1 shown, including:

[0030] lamp body 1;

[0031] The light distribution mirror 2 is arranged adjacent to the lamp body 1, and forms a welding surface 3 with the lamp body 1;

[0032] A plurality of light sources 4 are arranged along the welding surface 3 to emit laser beams 5, so that the laser beams 5 irradiate the welding surface 3 to melt the welding surface 3, thereby realizing the welding of the lamp body 1 and the light distribution mirror 2.

[0033] In this embodiment, the vehicle lamp includes a lamp body 1 and a light distribution mirror 2, the vehicle lamp and the light distribution mirror 2 are arranged oppositely, and the position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com