Ceramic body glazing mechanism with dual-position conveying function

A technology for ceramic blanks and feeding materials, which is applied to the field of glazing of ceramic blanks, can solve the problems of low work efficiency, intermittent blanks, enamel damage, etc., and achieves the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

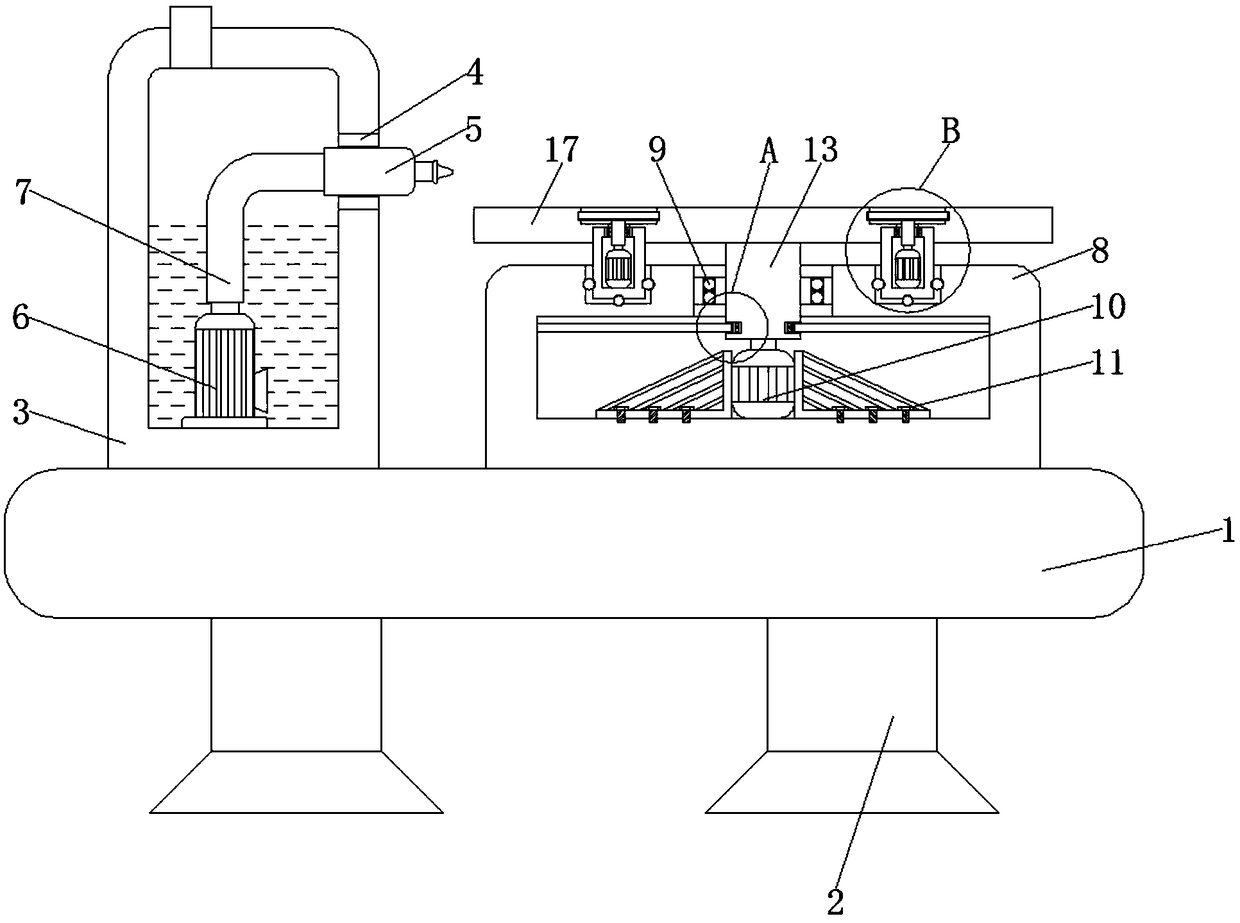

[0032] Such as Figure 1-3 As shown, a double-position feeding ceramic body glazing mechanism includes a support platform 1, support legs 2 are symmetrically fixedly connected to both sides of the bottom of the support platform 1, and a glaze storage box 3 is fixedly connected to the left side of the top of the support platform 1. The top of the right side of the glaze storage box 3 is provided with a first opening, the first opening is fixedly connected with a fixed gasket 4, the top of the right side of the glaze storage box 3 is provided with a spray gun 5, and the middle part of the bottom of the inner wall of the glaze storage box 3 is fixedly connected with a The delivery pump 6 is fixedly connected with a delivery pipe 7 in the middle of the top of the delivery pump 6 .

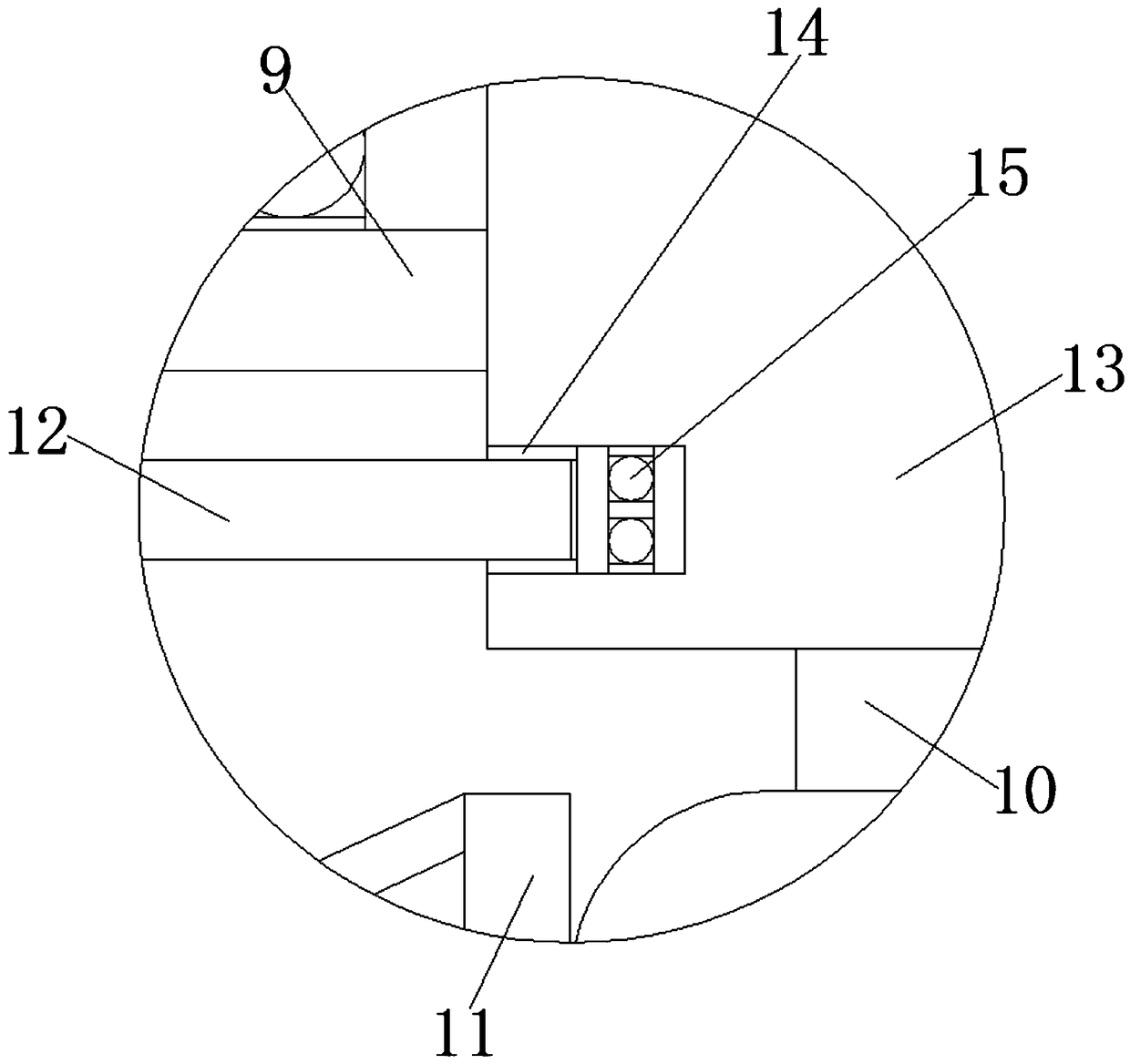

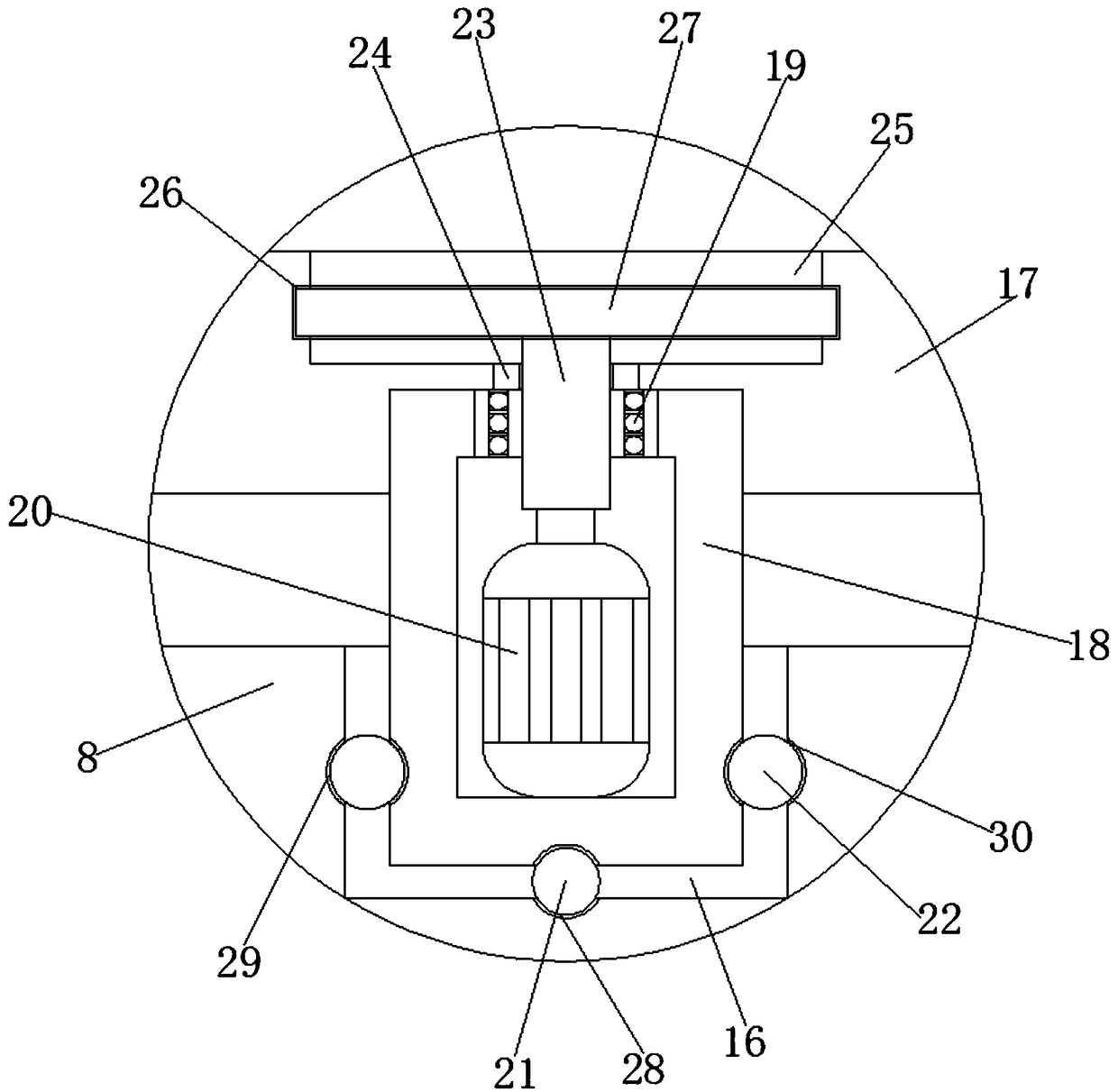

[0033]The right side of the top of the support table 1 is fixedly connected with a workbench 8, the middle of the top of the workbench 8 is provided with a second opening, the second opening is fixedly...

Embodiment 2

[0036] On the basis of Embodiment 1, the end of the spray gun 5 close to the glaze storage box 3 penetrates the fixed gasket 4 and extends to the inside of the glaze storage box 3, the spray gun 5 is attached to the fixed gasket 4 and fixedly connected, and the delivery pipe 7 is far away from the delivery One end of the pump 6 is fixedly connected to one end of the spray gun 5, through the cooperative work of the glaze storage box 3, the fixed gasket 4, the spray gun 5, the delivery pump 6, and the delivery pipe 7, the glaze material inside the glaze storage box 3 is absorbed. The ceramic body is sprayed with glaze to obtain a glaze layer with a suitable thickness, so that the ceramic body can be evenly glazed.

Embodiment 3

[0038] On the basis of Embodiments 1 and 2, the limit frame 11 is fixedly connected to the bottom of the inner wall of the workbench 8 by bolts, the limit frames 11 on both sides are respectively attached to the two sides of the first motor 10, and the first rotating shaft 13 The bottom runs through the first bearing 9 and extends to the inside of the workbench 8. The first rotating shaft 13 fits and is fixedly connected to the first bearing 9. An output shaft extends from the top of the first motor 10, and the output shaft of the first motor 10 is fixed. It is connected in the middle of the bottom of the first rotating shaft 13 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com