Wedge-shaped variable modulus multipore-lubricating spline shaft extrusion die with surface texture

An extrusion die and surface texture technology, applied in the direction of metal extrusion dies, etc., can solve the problems that the bottom of the spline shaft is easy to fold, affect the yield of the extruded spline shaft, and the dimensional accuracy is not high, so as to avoid the folding phenomenon , reduce the material accumulation phenomenon, reduce the effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

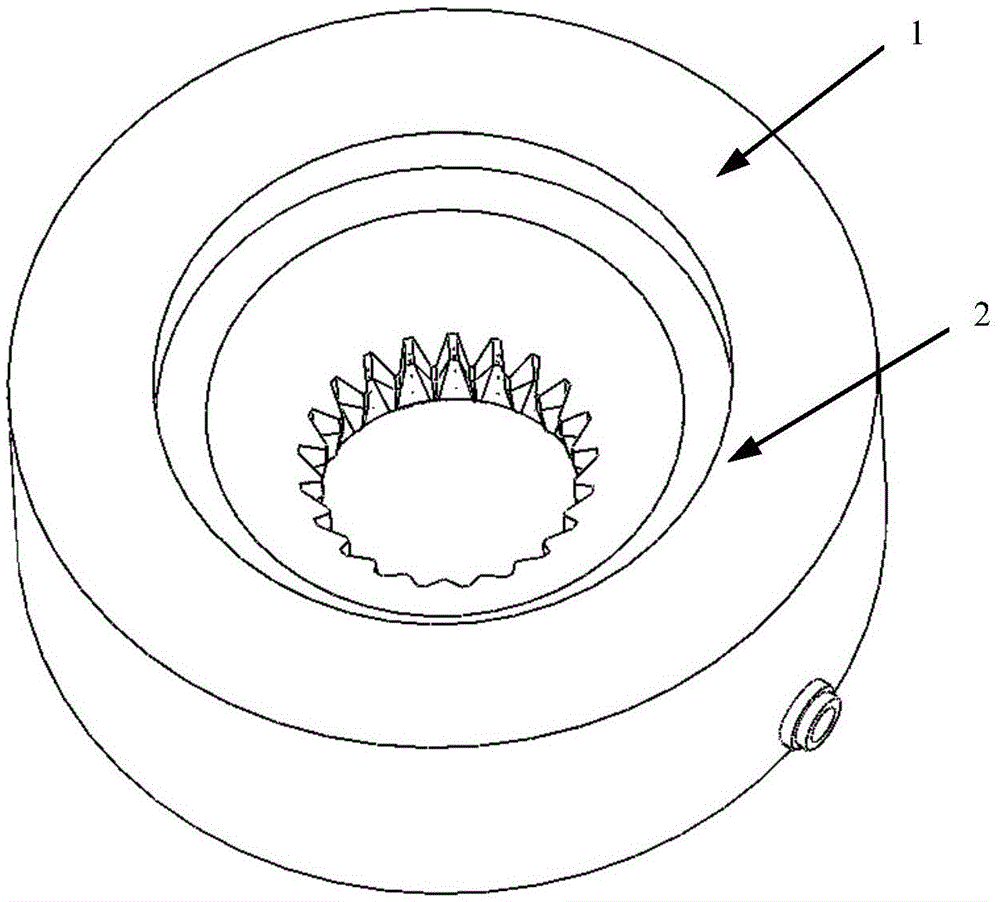

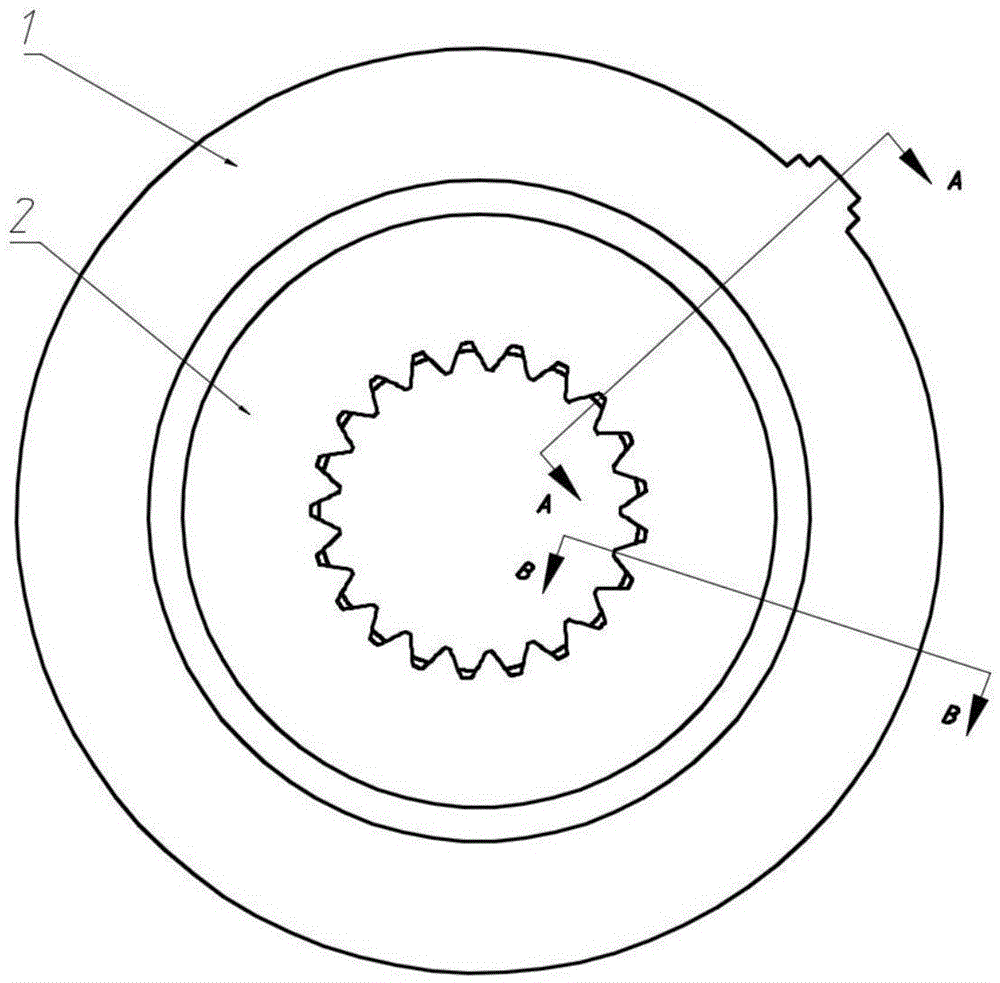

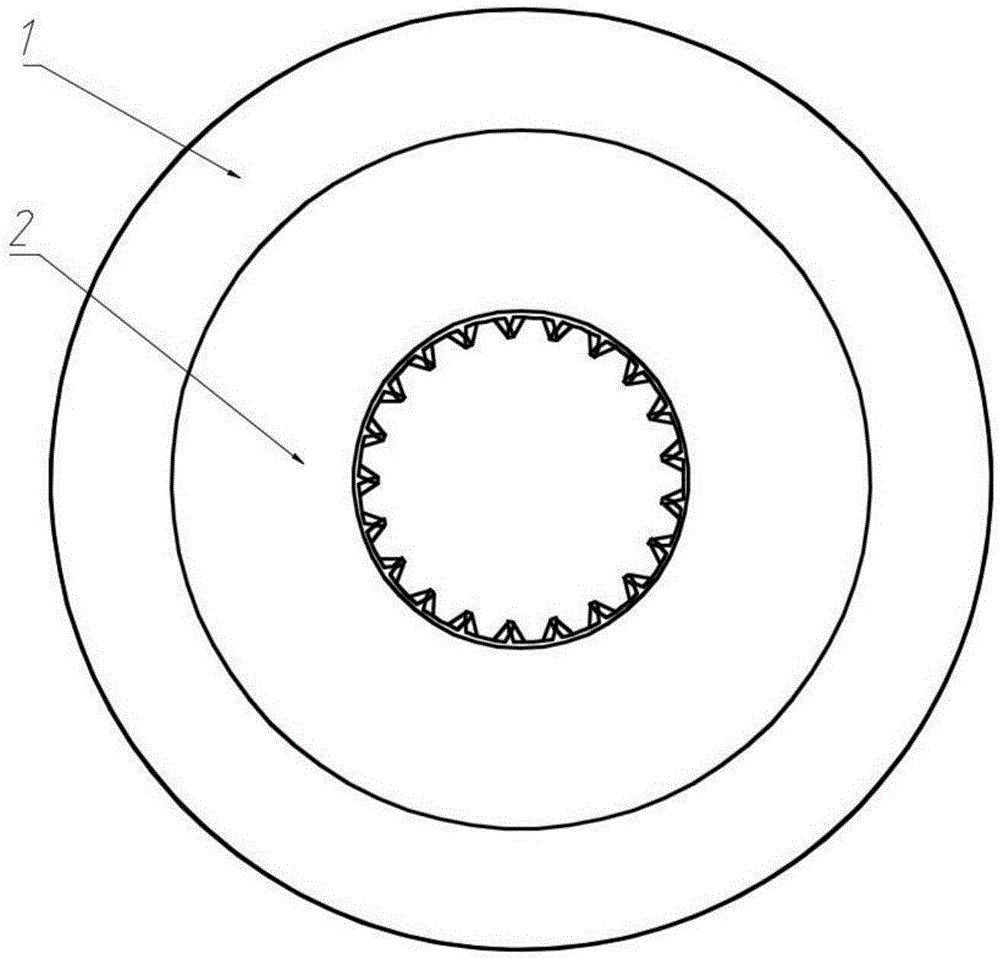

[0024] refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , a wedge-shaped variable modulus porous lubricated spline shaft extrusion die with surface texture, comprising an extrusion die 2 and a prestressing die fixing sleeve 1 connected externally, the prestressing die fixing sleeve 1 and the extrusion die 2 are Interference fit, the interference amount is 0.25mm, the sealing ring 3 is installed at the joint between the prestressing die fixing sleeve 1 and the extrusion die 2, and the sealing ring 3 is a metal sealing gasket, and the material is pure copper.

[0025] refer to Figure 4 and Figure 5 , the extrusion die 2 is provided with an upper bevel section I, a middle forming section II, and a wedge-shaped transition section III.

[0026] refer to figure 2 , image 3 , the wedge-shaped transition section III tooth modulus of the extrusi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com