Unit used for machining fluorite mineral aggregate and application thereof

A technology for mineral materials and units, applied in wet separation, mobile filter element filters, flotation, etc., can solve the problems of low processing efficiency, high noise, and high equipment damage frequency of fluorite mineral materials, and achieve extended life and sanitation. The effect of environment and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

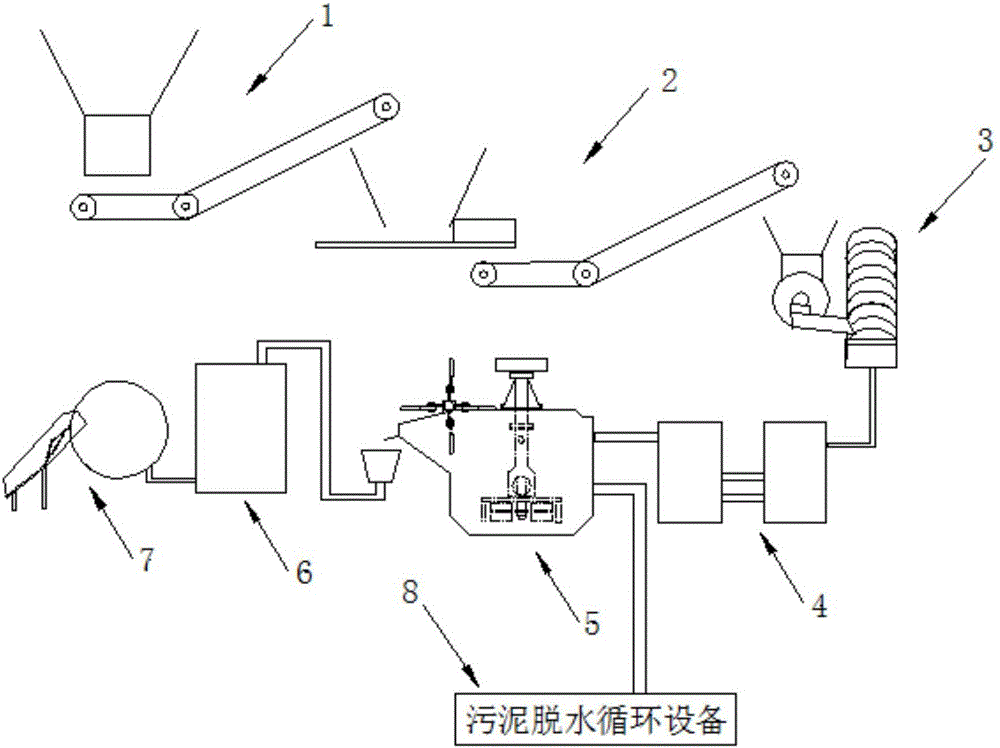

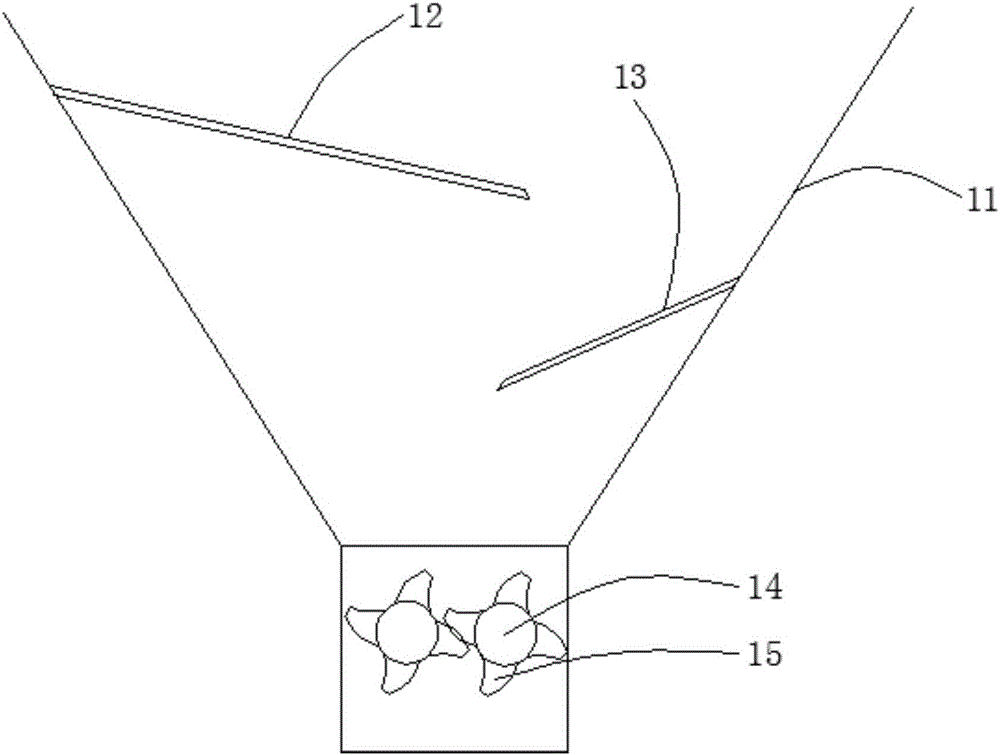

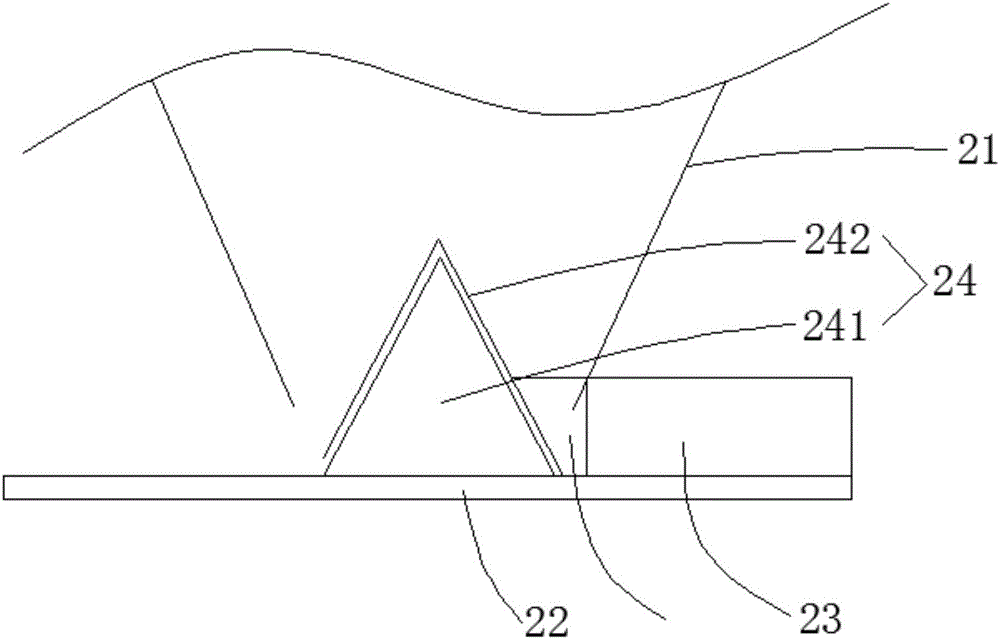

[0051] like figure 1 As shown, a unit for processing fluorite ore, according to the processing route of the ore, the unit includes a crusher 1, a disc feeder 2, a grinding device 3, a stirring device 4, a flotation machine 5, Concentrator 6 and rotary drum vacuum filter 7; Crusher 1 breaks large mineral materials into fine materials; Crusher 1 conveys the fine materials to the disc feeder 2 through the conveyor belt; The belt transports the fine material to the grinding device 3; the grinding device 3 processes the fine material into pulp; the grinding device 3 transports the pulp to the stirring device through the pipeline; to the flotation machine 5; the flotation machine 5 carries out multi-stage flotation to the ore pulp mixed wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com