Multifunctional IGBT driving circuit

A drive circuit and multi-functional technology, applied in the direction of output power conversion devices, electrical components, etc., can solve the problems of affecting accuracy, reducing the reliability of IGBT module equipment, and complex application conditions, so as to avoid the interference of external factors , Improving application flexibility and improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

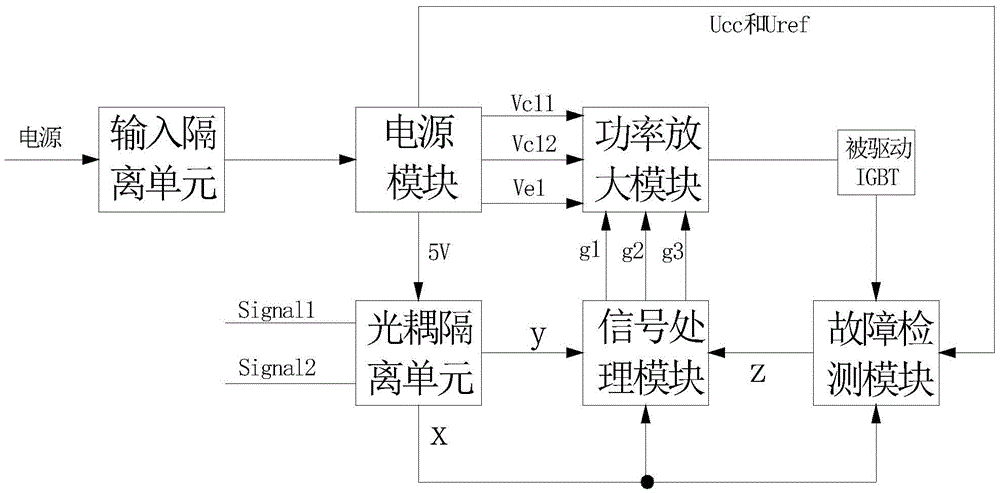

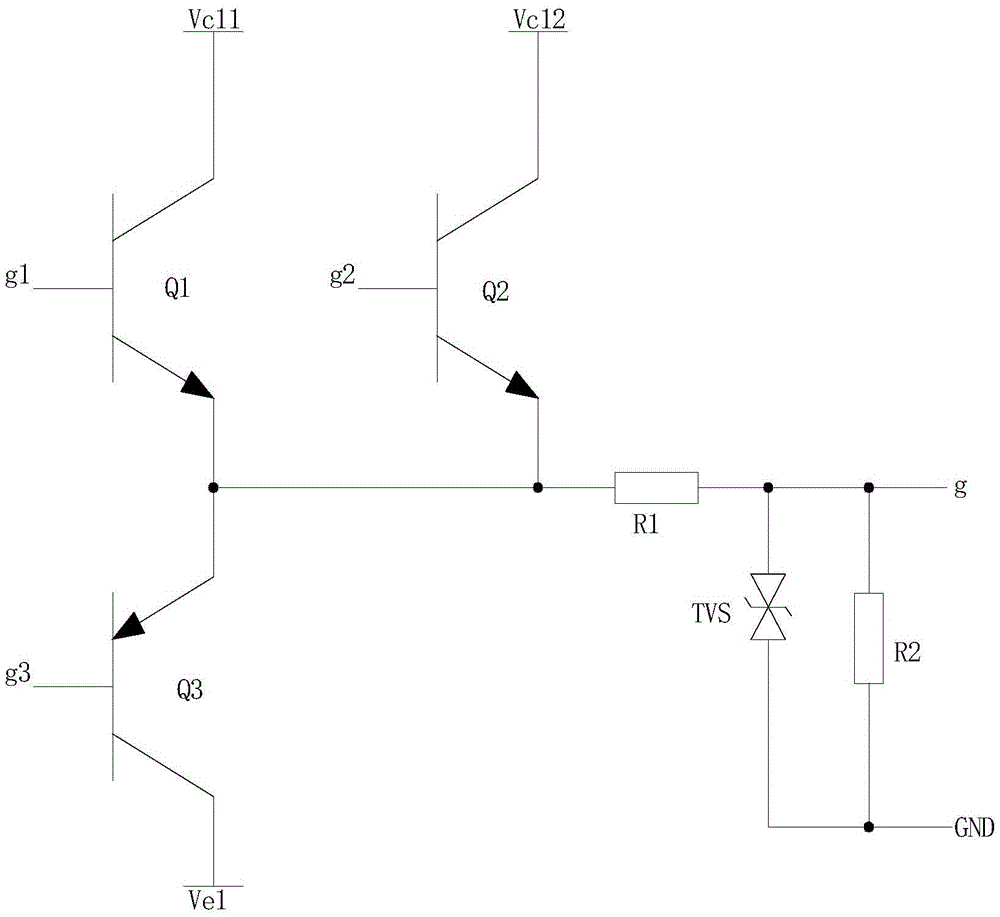

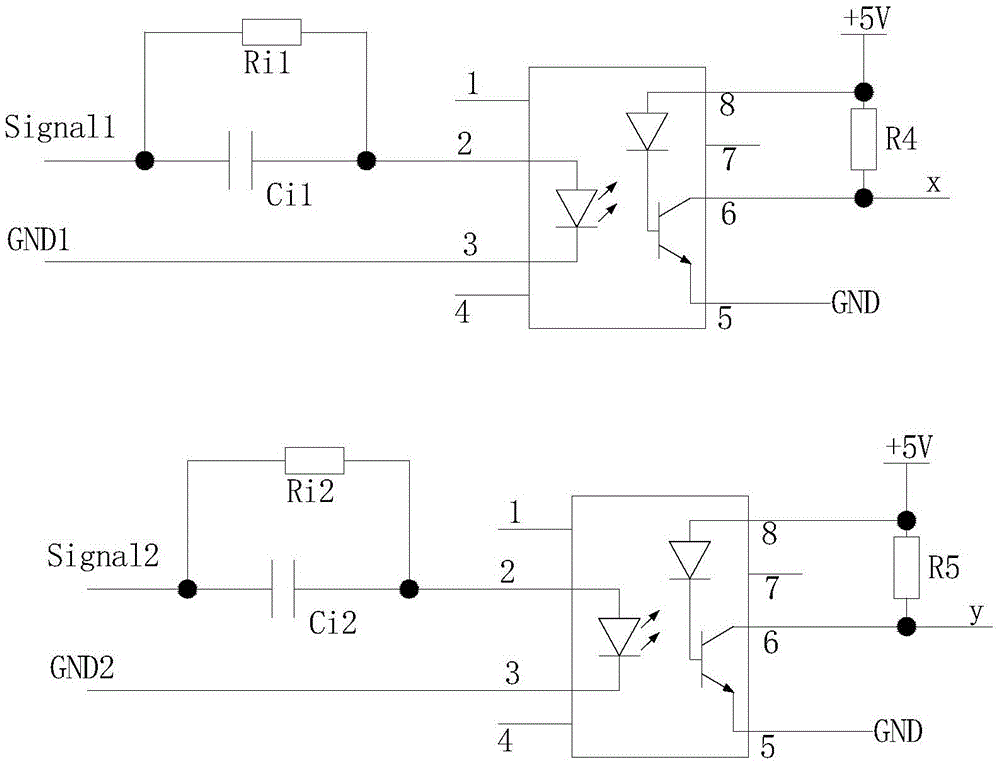

[0026] figure 1 It is a block diagram of the present invention, figure 2 It is the circuit schematic diagram of the power amplification module of the present invention, image 3 It is the circuit schematic diagram of the optocoupler isolation unit of the present invention, Figure 4 It is the circuit principle diagram of the fault detection unit of the present invention. As shown in the figure, a multifunctional IGBT drive circuit provided by the present invention includes a power supply module, a signal processing module and a power amplification module, and the power supply module contributes to the signal processing module and the power amplification module supply power, the signal processing module outputs a control signal to the power amplification module, and the power amplification module outputs an IGBT drive signal, an IGBT test signal or an IGBT shutdown signal according to the control signal output by the signal processing module, through this The structure can n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com