Polypropylene porous membrane for lithium-ion battery and preparation method of polypropylene porous membrane

A technology for lithium-ion batteries and porous diaphragms, which is applied to battery components, circuits, electrical components, etc., can solve the problems of weak puncture resistance and high porosity, and achieve uniform strength, strong tensile strength, and moderate size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

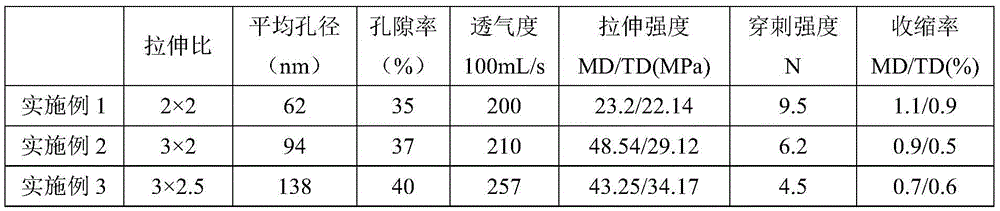

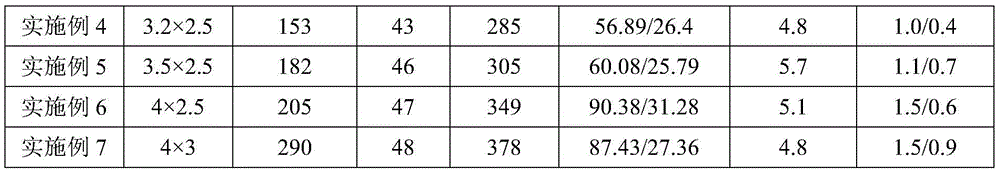

Embodiment 1

[0032] The lithium-ion battery polypropylene porous diaphragm in the present embodiment, raw material is made up of the component of following quality: 2,2'-methylene-di(4,6-di-tert-butylphenol) sodium phosphate 1.5g, sodium benzoate 0.5g, polypropylene resin 2.0kg. Among them, the polypropylene resin has a viscosity average molecular weight of 1.3×10 4 The isotactic resin has a melt index of 15g / 10min.

[0033] The preparation method of polypropylene porous diaphragm, comprises the following steps:

[0034] 1) Accurately take polypropylene resin, 2,2'-methylene-bis(4,6-di-tert-butylphenol) sodium phosphate and sodium benzoate according to the quality, and heat to 180°C to obtain a melt;

[0035] 2) The melt is extruded from the die, cooled and cast into a thick sheet on a cooling roll, and the cooling temperature is 90°C;

[0036] 3) Take the thick sheet and carry out successive stretching at 135°C to 2 times in the vertical direction and then 2 times in the transverse dir...

Embodiment 2

[0039]The lithium-ion battery polypropylene porous diaphragm in the present embodiment, raw material is made up of the component of following quality: 2,2'-methylene-di(4,6-di-tert-butylphenol) calcium hydrogen phosphate 15.0g, benzene Calcium formate 5.0g, polypropylene resin 2.0kg. Among them, the polypropylene resin has a viscosity average molecular weight of 3.0×10 4 A random resin with a melt index of 10g / 10min.

[0040] The preparation method of polypropylene porous diaphragm, comprises the following steps:

[0041] 1) Accurately take polypropylene resin, 2,2'-methylene-bis(4,6-di-tert-butylphenol) calcium hydrogen phosphate and calcium benzoate according to the quality, and heat to 210°C to obtain a melt;

[0042] 2) Extrude the melt from the die, cool it on a cooling roll and cast it into a thick sheet at a cooling temperature of 100°C;

[0043] 3) Take the thick sheet and stretch it at 135°C to 3 times in the vertical direction and then 2 times in the transverse di...

Embodiment 3

[0046] The lithium-ion battery polypropylene porous diaphragm in the present embodiment, raw material is made up of the component of following quality: Methylene bis (2,4-di-tert-butylphenoxy) aluminum phosphate 23.0g, magnesium benzoate 17.0g, Polypropylene resin 2.0kg. Among them, the polypropylene resin has a viscosity average molecular weight of 1.1×10 5 The syndiotactic resin has a melt index of 7.8g / 10min.

[0047] The preparation method of polypropylene porous diaphragm, comprises the following steps:

[0048] 1) Accurately take polypropylene resin, methylene bis(2,4-di-tert-butylphenoxy)aluminum phosphate and magnesium benzoate according to the quality, and heat to 210°C to obtain a melt;

[0049] 2) The melt is extruded from the die, cooled and cast into a thick sheet on a cooling roll, and the cooling temperature is 110°C;

[0050] 3) Take the thick sheet and carry out successive stretching at 140°C at a ratio of 3 times in the longitudinal direction and then 2.5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com