A carbon nanofiber/diamond composite film material and its application as a thermal battery energy conversion device

A carbon nanofiber, diamond thin film technology, applied in the direction of thermoelectric device node lead wire material, etc., can solve problems such as complex equipment system, application limitation, etc., to achieve the effect of improving light-heat transmission efficiency and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

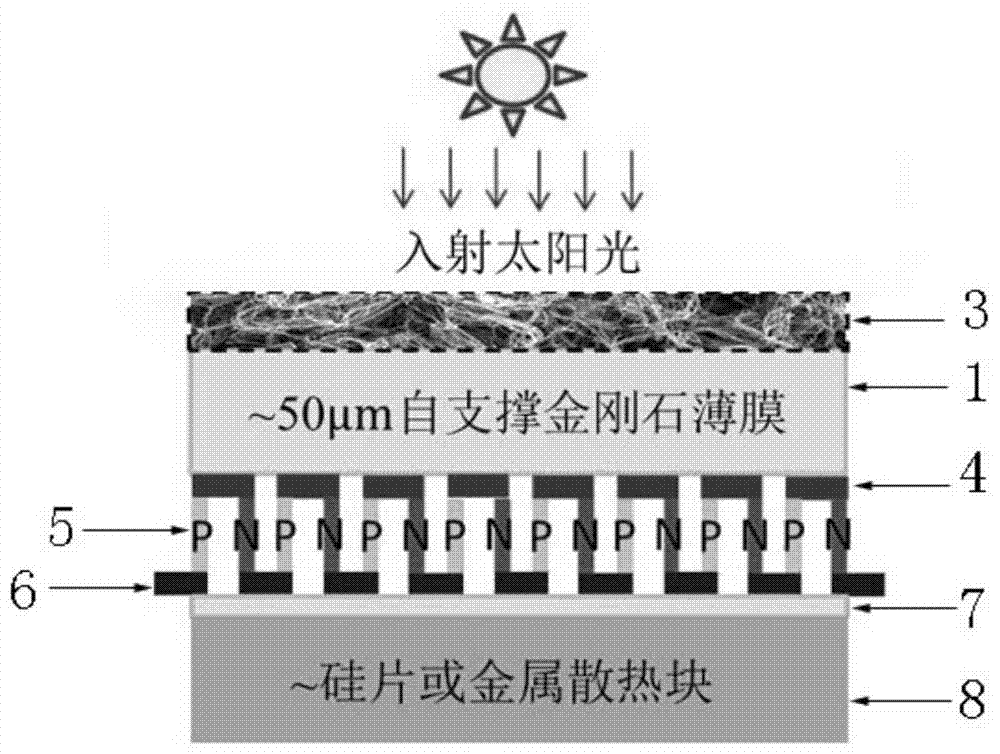

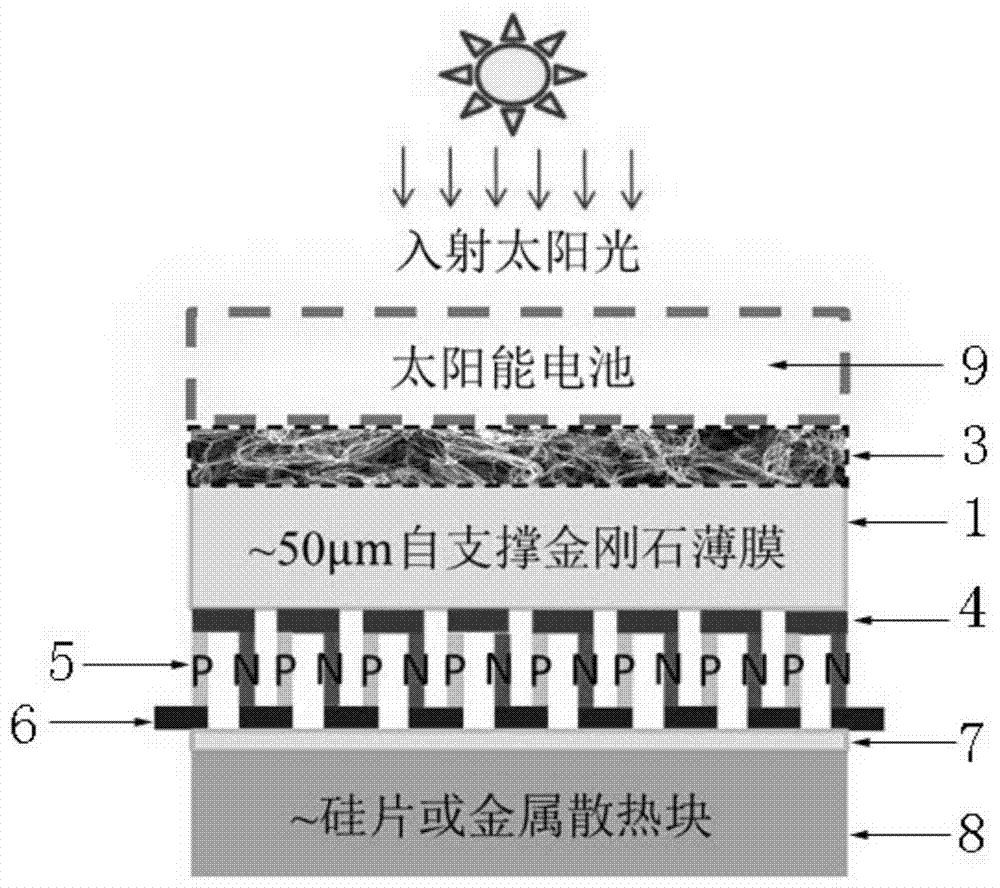

[0040] The preparation process of the carbon nanofiber / diamond composite film material in this embodiment is as follows:

[0041] (1) On the polished silicon wafer substrate, select the microwave plasma chemical vapor deposition method to prepare a diamond film, then soak it in a KOH solution with a concentration of 20wt.% at 75°C, peel off the silicon wafer substrate after soaking for 12 hours to obtain Self-supporting diamond film; the process parameters of the microwave plasma chemical vapor deposition method are as follows: the microwave power is 3000 watts, the air pressure is 5-100 Torr, the raw gas is methane and hydrogen (carrier gas), and the methane content is 10%. The roughness of the silicon wafer base used is less than 5nm, the thickness of the silicon wafer base is 300-500 μm, and the silicon wafer base is preferably a doped p / n type silicon wafer, which is conducive to the growth of diamond.

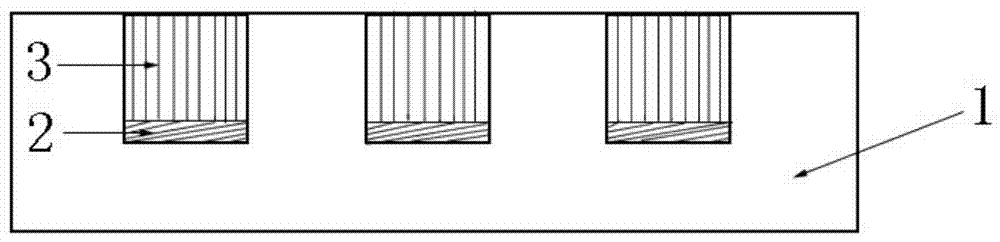

[0042] (2) Prepare a groove structure on the surface of the diamond f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com