Combined double electromagnetic gas injection device

An injection device, dual electromagnetic technology, applied in the direction of fuel supply device, charging system, combustion engine, etc., can solve the problems of affecting control accuracy, large circulating injection volume, and unstable injection, so as to ensure reliability and stability, The effect of simplified engine structure and flexible jet pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with legend the present invention is described in more detail:

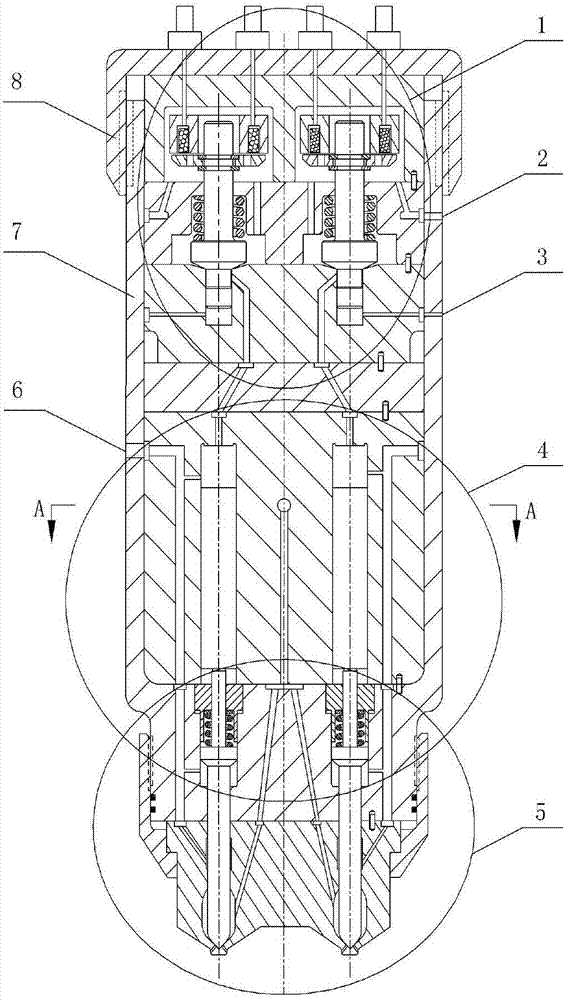

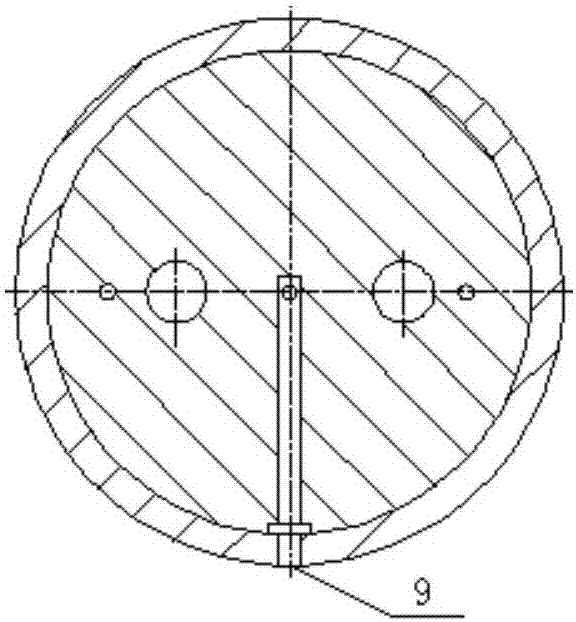

[0023] combine Figure 1(a) to Figure 1(b) , The combined double electromagnetic gas injection device of the present invention is mainly composed of a double solenoid valve part 1, a double control piston part 4, a double needle valve nozzle part 5, an injection device body 7 and an upper end cover 8 of the injection device. The injection device body 7 has a first low-pressure oil drain port 2, a second low-pressure oil drain port 3, a control oil inlet 6, a gas inlet 9, etc., and the oil passage at the gas inlet is shown in Figure 1(b).

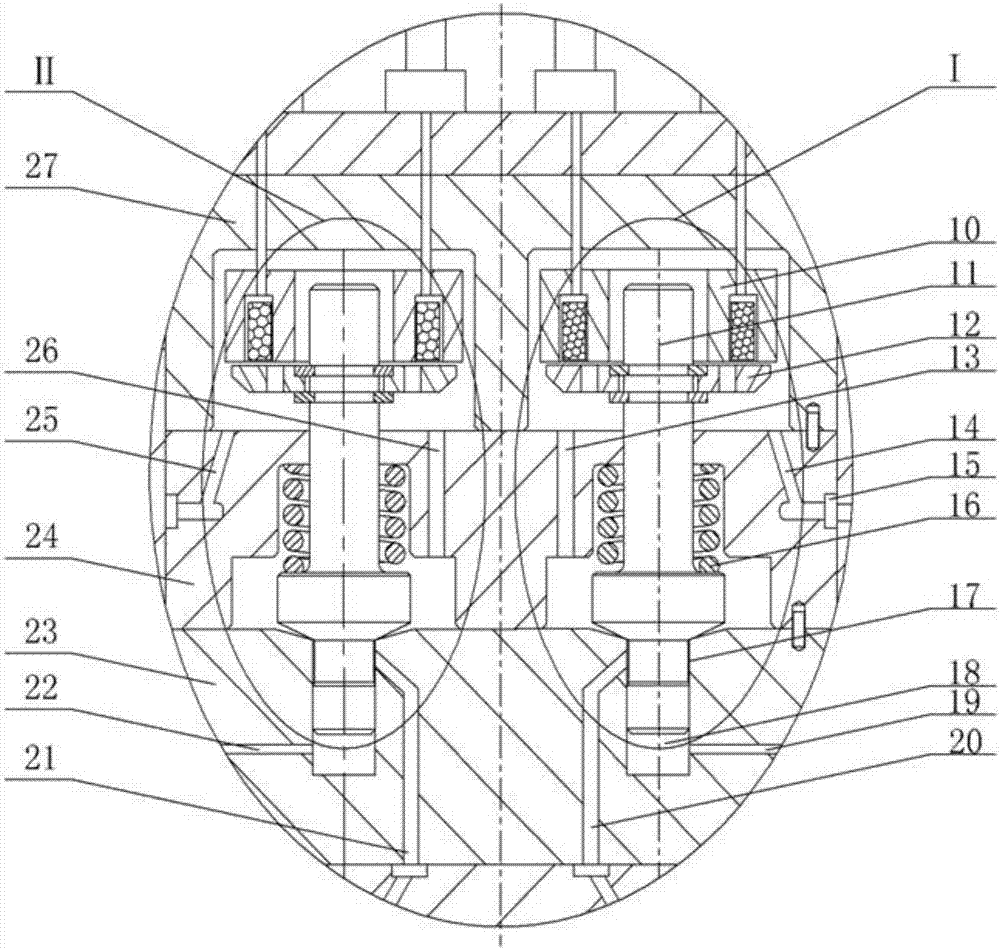

[0024] combine figure 2, double solenoid valve part 1 mainly includes solenoid valve Ⅰ, solenoid valve Ⅱ, solenoid valve body 27, solenoid valve spring seat 24, valve stem sealing base 23, etc. The structure and installation method of solenoid valve Ⅰ and solenoid valve Ⅱ are the same. The device is symmetrically distributed and shares the electrom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com