Series-tied-arch-type prestressed steel structure cantilever system

A prestressed steel and arch-type technology, applied in special structures, building components, building structures, etc., can solve problems such as difficult to meet the bearing capacity and deformation, achieve convenient construction process, improve bearing capacity and stiffness, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

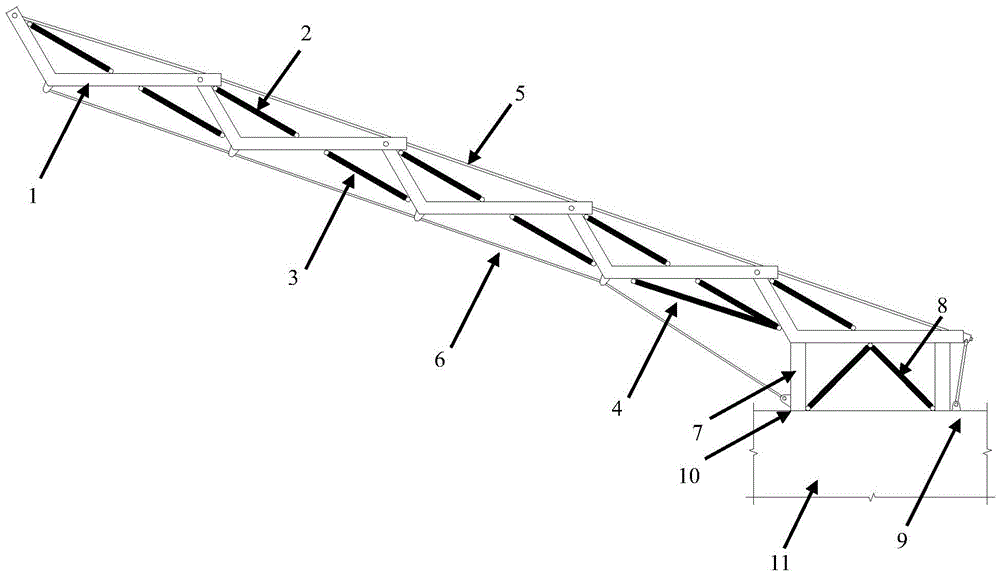

[0021] figure 1 It is a schematic diagram of the structure of the cantilever system of the series tie rod arch type prestressed steel structure using the support diagonal brace in the embodiment of the present invention.

[0022] Such as figure 1 As shown, the arch-type prestressed steel structure cantilever system with tie rods in series has: L-shaped steel arch beam 1, arch inner support 2, arch back support 3, additional arch back support 4, force cable 5, stabilizing cable 6, support column 7 , Support diagonal support 8, force cable support 9, stable cable support 10 and base 11.

[0023] The L-shaped steel arch beam 1 adopts beam-type members or truss-type members such as H-shaped cross-section and box-shaped cross-section. The L-shaped steel arch beam 1 in this embodiment has: a side and a bottom, the two sides are connected to form an L shape, and the angle between the two sides should be between 90° and 120°. The number of L-shaped steel arch beams 1 can be two or ...

Embodiment 2

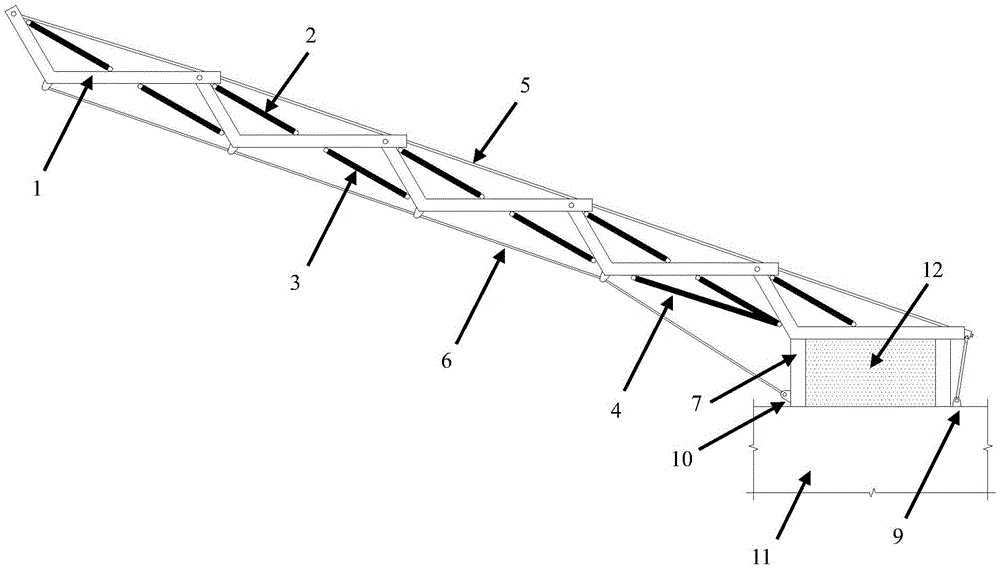

[0039] figure 2 It is a schematic diagram of the structure of the cantilever system of the series tie rod arch type prestressed steel structure using the support shear wall in the embodiment of the present invention.

[0040] Such as figure 2 As shown, in this embodiment, the support shear wall 12 is used instead of the support brace 8, and the structures and connection methods of the rest of the components are the same as those in the first embodiment.

[0041]The support shear wall 12 is arranged within the range surrounded by two adjacent support columns 7 , the bottom edge of the lowermost L-shaped steel arch beam 1 and the base 11 .

[0042] The support shear wall 12 is used to improve the shear resistance of the connection between the cantilever part of the structural system and the base 11, and walls including concrete shear walls and steel plate shear walls can be used. In this embodiment, the support shear wall 12 is a steel plate shear wall.

[0043] Function an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com