A retractable manual digging pile support structure and its construction method

A technology of manual excavation piles and construction methods, which is applied in the direction of excavation, sheet pile walls, foundation structure engineering, etc., can solve the problems of water accumulation at the bottom of the hole, large soil disturbance around the pile, and difficult construction, so as to facilitate the filling of gaps and dense, fast and efficient construction, and low overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

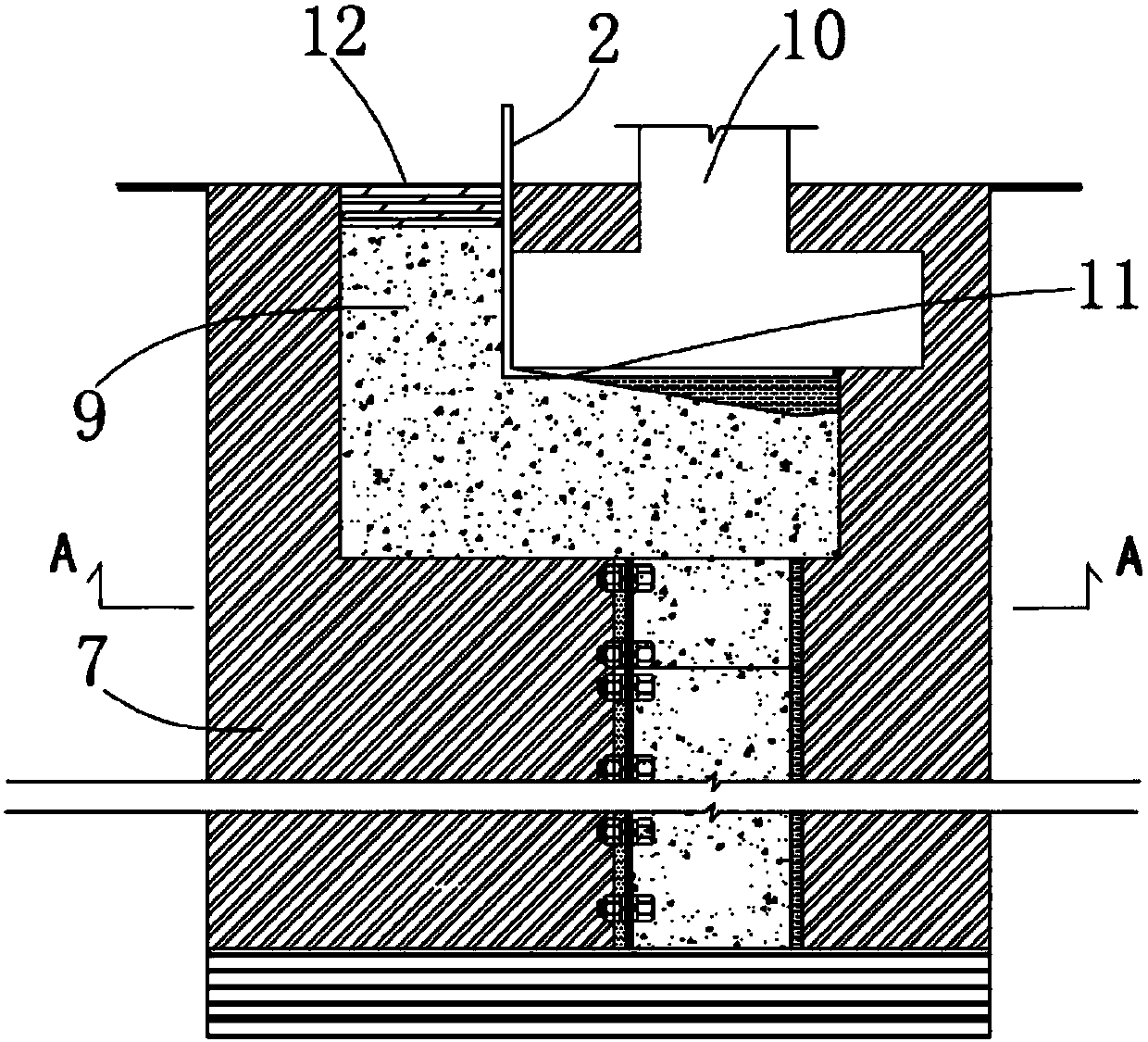

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

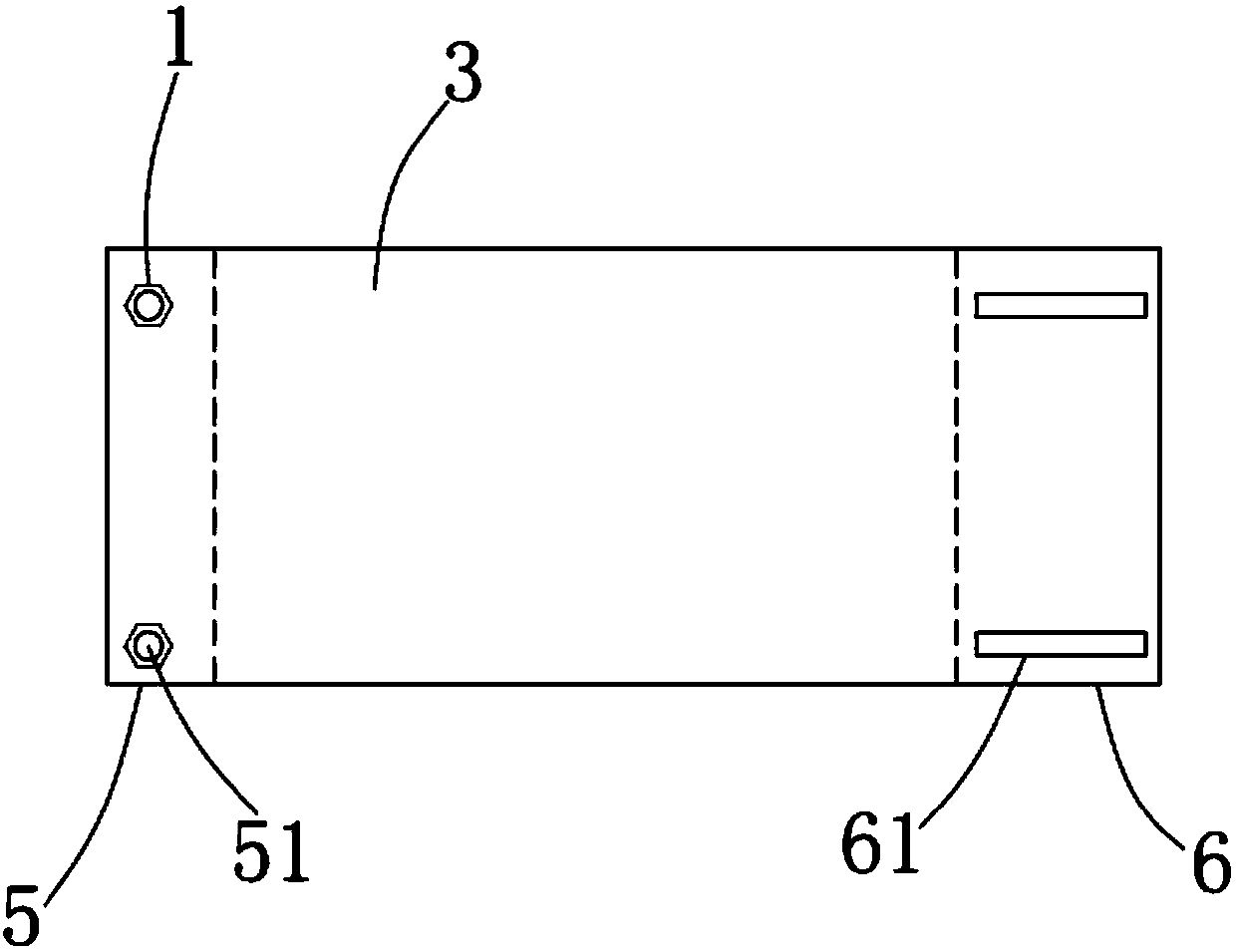

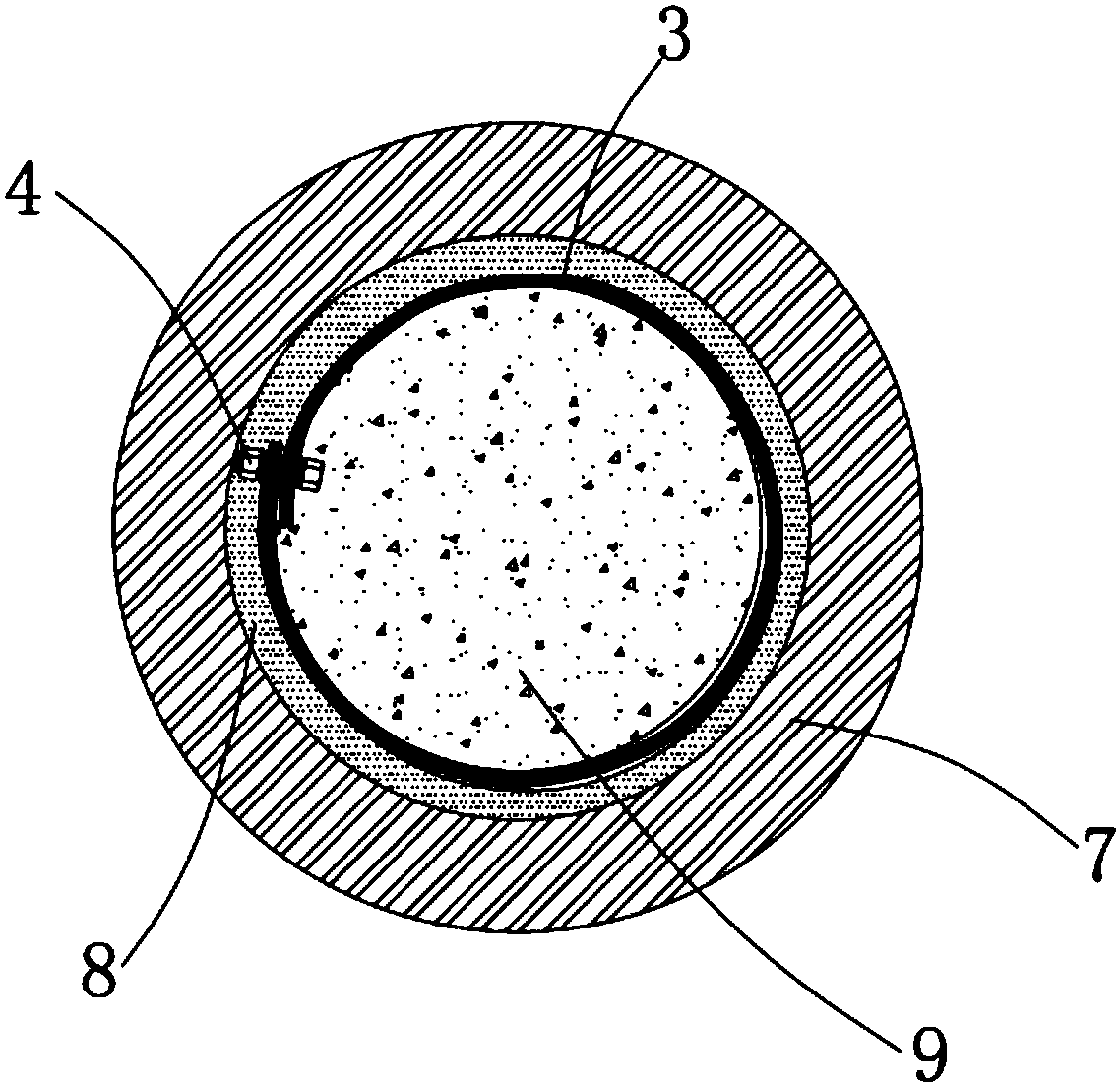

[0031] see Figure 1 to Figure 3 , the retractable artificial hole-digging pile support structure includes a nut 1, a conduit 2, a steel plate 3, a bolt 4, a first connecting portion 5 and a second connecting portion 6 formed on two opposite sides of the steel plate 3, the The first connecting part 5 is formed with a bolt hole 51, the second connecting part 6 is formed with a slide groove 61, and the first connecting part 5 and the second connecting part 6 are stacked so that the steel plate 3 is wound to form The position of the bolt hole 51 corresponds to that of the chute 61, and the bolt 4 is inserted into the bolt hole 51 and the chute 61, so that the first connecting part 5 and the second connecting part 6 are fixedly connected. , the nut 1 is welded to the bolt hole 51 .

[0032] The steel plate 3 is a rectangular steel plate, the first connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com